STAMPING INDUSTRY

Scrap disposal with

three movable containers

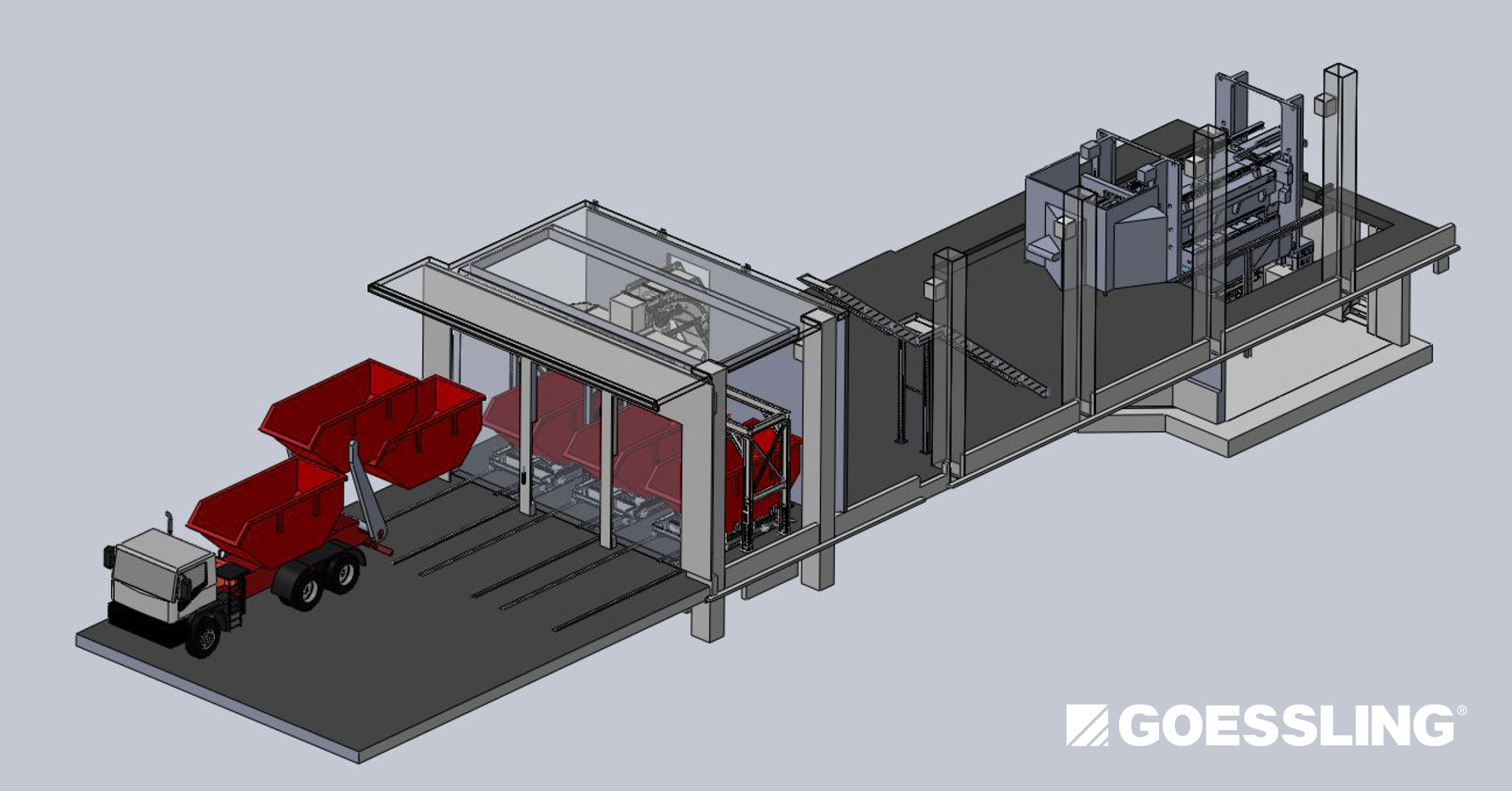

GOESSLING Conveying Technology for stamping scrap in chassis

manufacturing.

![]()

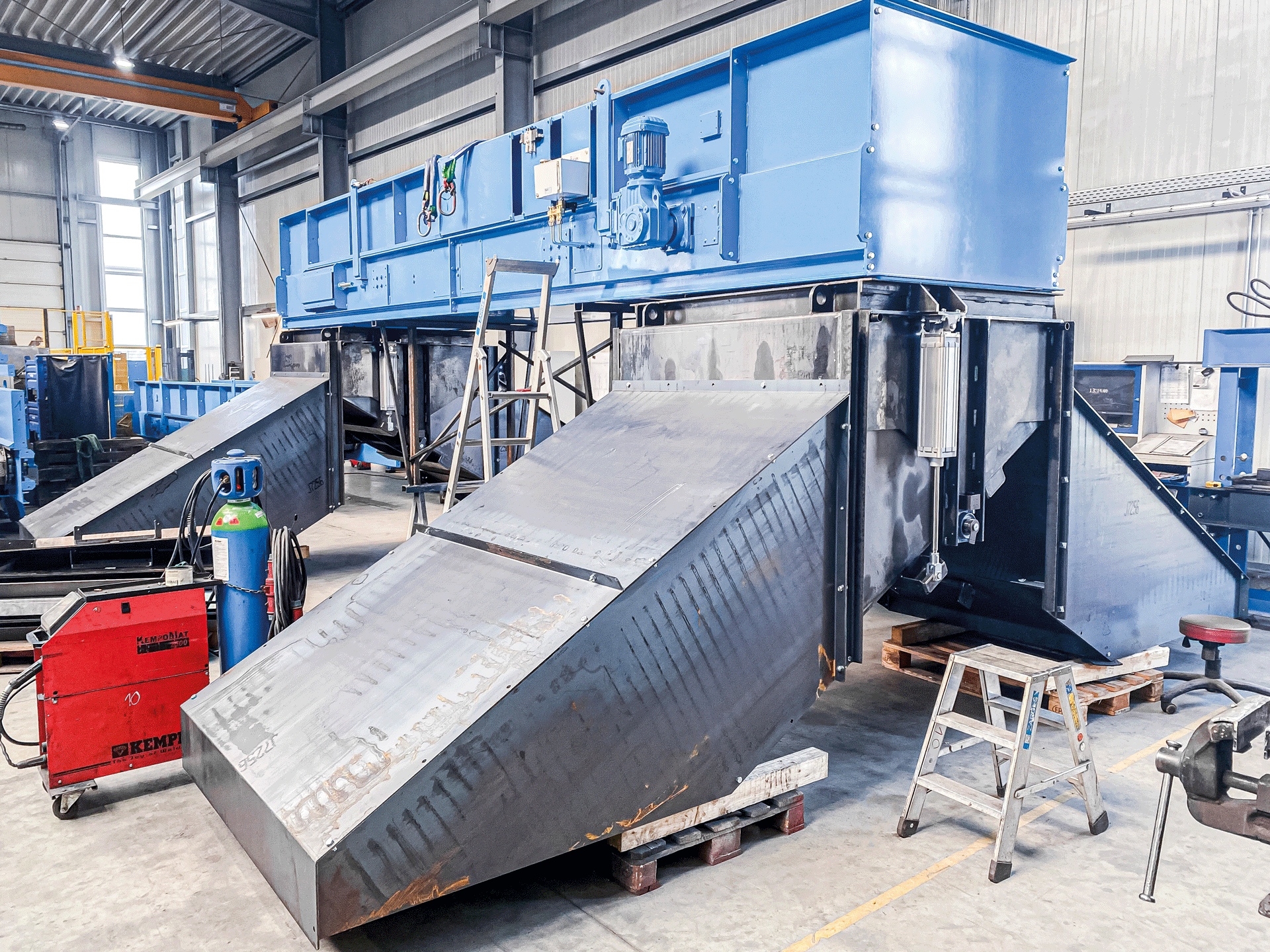

This year in September, the division GOESSLING delivered a customized conveying solution to a long-term client that once again relied on the high quality and positive user experience.

When manufacturing chassis parts, stamping scrap occurs beneath the stamping press. These scrap parts must be disposed in containers. Using their experience in GOESSLING conveying technology, JOEST was able to offer the client a robust solution with excellent service.

The special challenge of this project was that the stamping scrap is charged over a special chute system in the basement onto a Double-Z-Conveyor with an effective width of 625 mm. The scrap is then transferred on a reversible conveyor with the same effective width. At the the transitions, the reversible conveyor has pivoting chutes. The both pivoting slides enable the oily scraps to be distributed into three displaceable containers.

The conveying system, made from aluminum, steel, stainless-steel and galvanized sheet metal is low-maintenance and is delivered in an oil-tight configuration. Stamping scrap can be conveyed at a throughput of four to six tons per hour.

Weitere Beiträge

Happy International Women’s Day!

Today, we want to give special thanks to all women! Our worker’s council, in collaboration with IG Metall, is bringing smiles to the faces of the women in the #JOESTeam with fresh colorful primroses!

For our long-standing customer, Dyckerhoff company, we have now exchanged JOEST tube type feeder at two star distributors for silo loading during the winter overhaul for the 4th year in a row, thus reaching the halfway point of the overall project.

Excited to finally announce the launch of our new website! Find out about our solutions in bulk material handling! Explore now and let’s elevate your efficiency together!