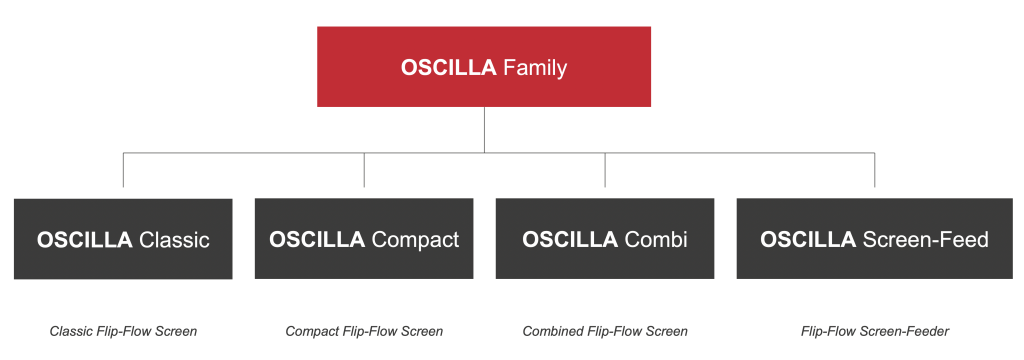

Screening challenging and inhomogeneous products requires special processing technology. During operation, blockages in the screen are almost entirely prevented and the material is dispersed to enable fine grain separation. Conventional screens are usually unable to deliver this performance – this is where JOEST Flip-Flow Screens from the OSCILLA Family are used. Typical cross cuts range between 0,5 and 40 mm.

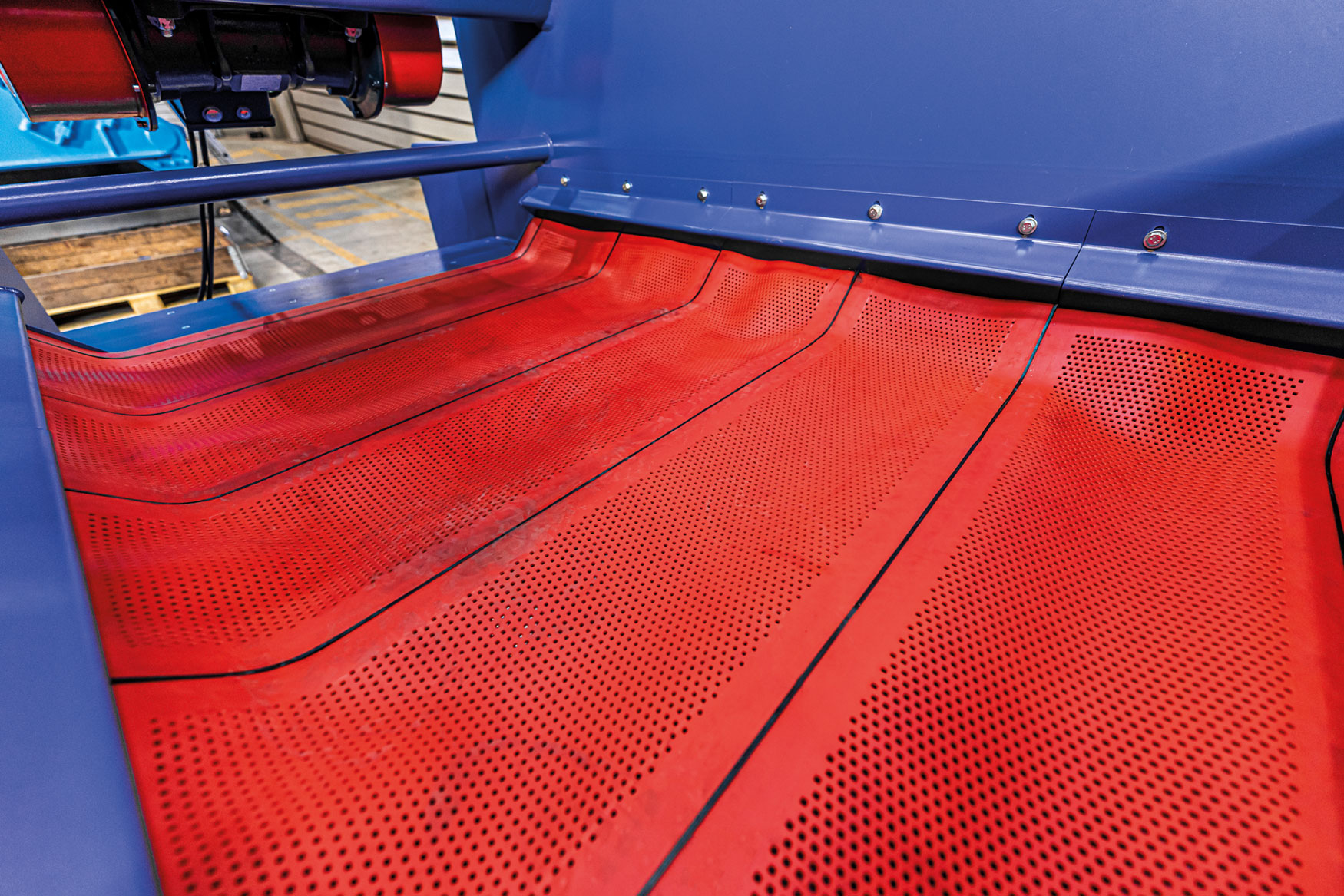

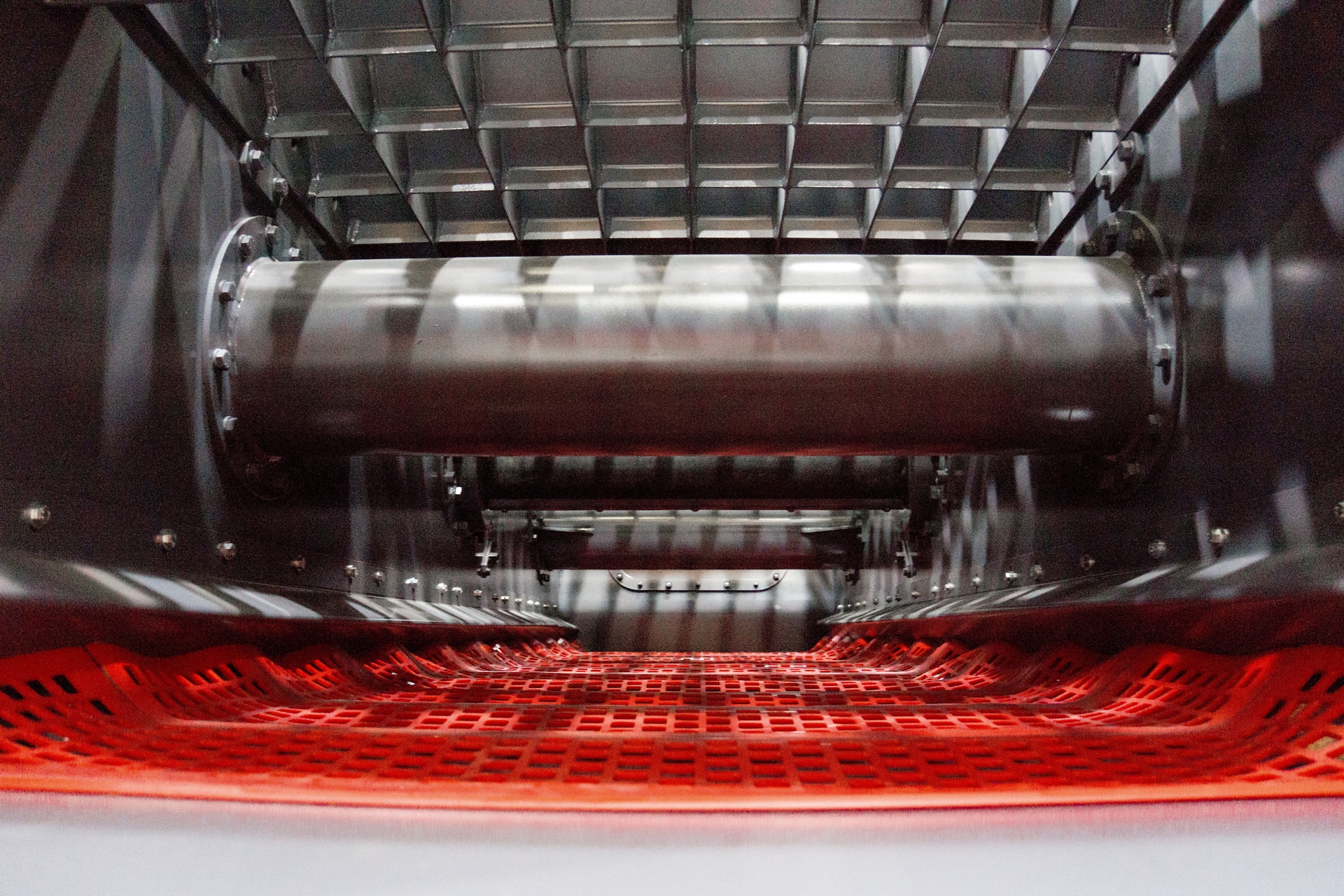

The OSCILLA Family of JOEST Flip-Flow Screens is based on a resonance system. The internal screen frame performs a relative motion in reaction to the directly excited external frame. Flexible polyurethane screens are attached to both frames with one side each. The relative motion of the frames exerts and releases tension on the screens, resulting in acceleration rates of up to 50 G on the screen deck.

The newly designed Vibroblocks combined with aluminum cross bars enable larger oscillation amplitudes and acceleration rates than conventional Flip-Flow Screens.

This design allows for a combination of multiple decks, such as a Flip-Flow Screen with a conventional Screen on top. Depending on the application, all available screen types from wire-mesh and perforated plates to rod-screens and PU clip systems can be implemented.

Best product dispersing results and high screening efficiency with acceleration rates > 50 G

Energy efficient due to optimized oscillating weight

In-house drive manufacturing

Reduced maintenance cost and high availability thanks to clamped screening mats and easily accessible spring elements

Fully bolted design

D E T A I L S

Feed Product up to 100 mm and Screen Cut up to 40 mm.

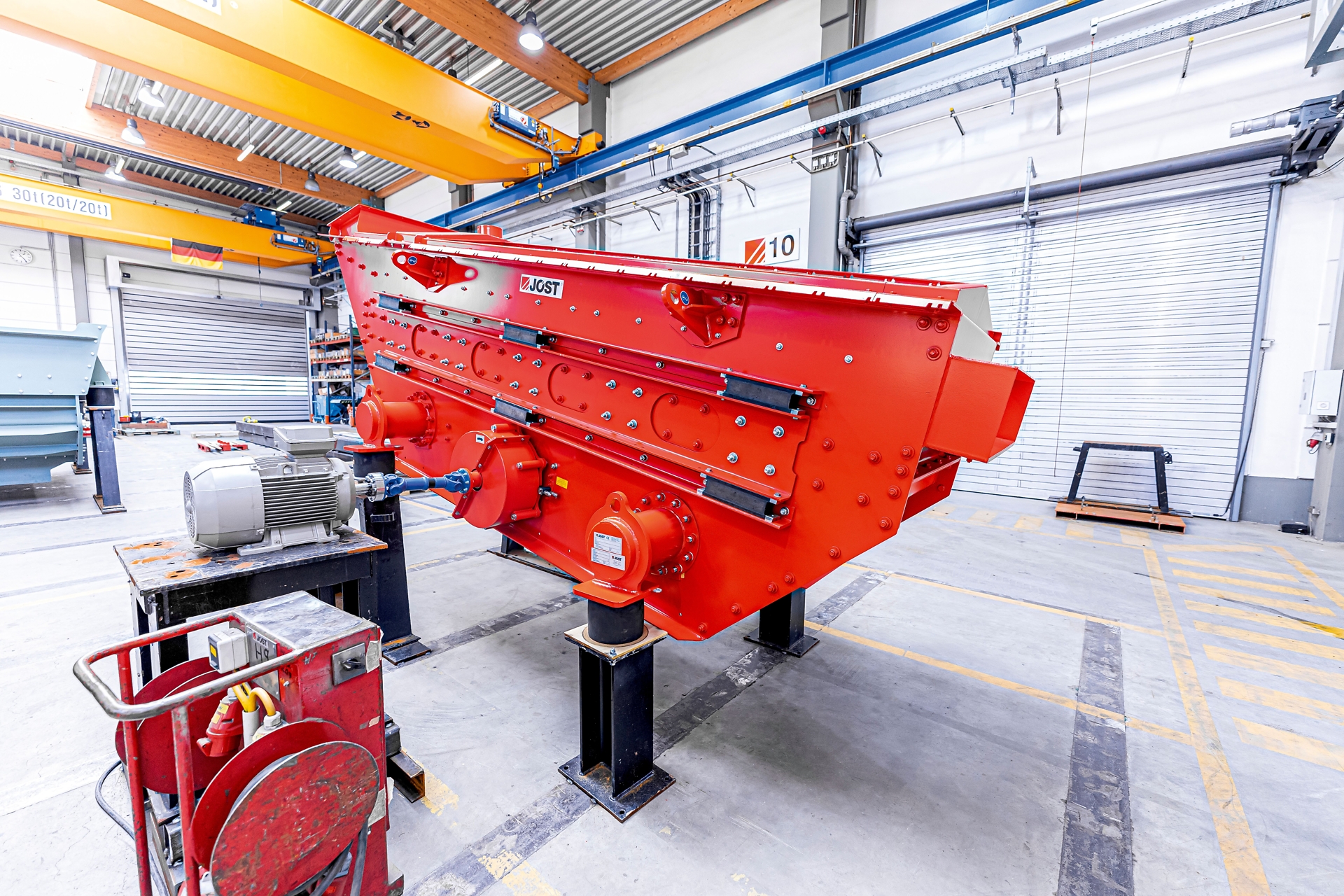

In the OSCILLA Classic version of this Flip-Flow Screen, the base frame is set into a circular motion. This excites the internal frame, creating an overlay of oscillations. The overlay enhances material flow by exerting additional acceleration forces on the product. Even if the machine was overflowing with material, it would be capable of clearing itself. The decline angle can be reduced to a minimum of 10 degrees.

The drive system of the Flip-Flow Screen is available with grease or oil lubrication.

Applications for the OSCILLA Classic range from plastics, domestic and industrial waste and shredded scraps to compost, ores, minerals and coals.

Reduced plant and processing costs by use of multiple, individually adjustable screening decks

Small influence of heavy loads

Robust design

Choice of grease or oil lubrication

Wear protection and anti-stick coatings

Electronic machine surveillance

Electronic control of oscillation amplitude

ATEX-Version

Dust tight Version

Air Suspension

| 2.640 | 3.300 | 3.960 | 5.300 | 5.940 | 7.260 | 7.920 | |

|---|---|---|---|---|---|---|---|

| 600 | x | ||||||

| 900 | x | ||||||

| 1.200 | x | ||||||

| 1.500 | x | x | |||||

| 2.100 | x | x | |||||

| 2.400 | x | x | x | ||||

| 3.000 | x | x |

ASR

Demoliton Waste

Glass Recycling

Industrial Waste

Metal Scraps

MHW

Plastic

RDF

Shredder Heacy Fraction

Shredder Light Fraction

Slag

WEEE

D E T A I L S

Product Feed up to 100 mm and Screen Cut up to 40 mm.

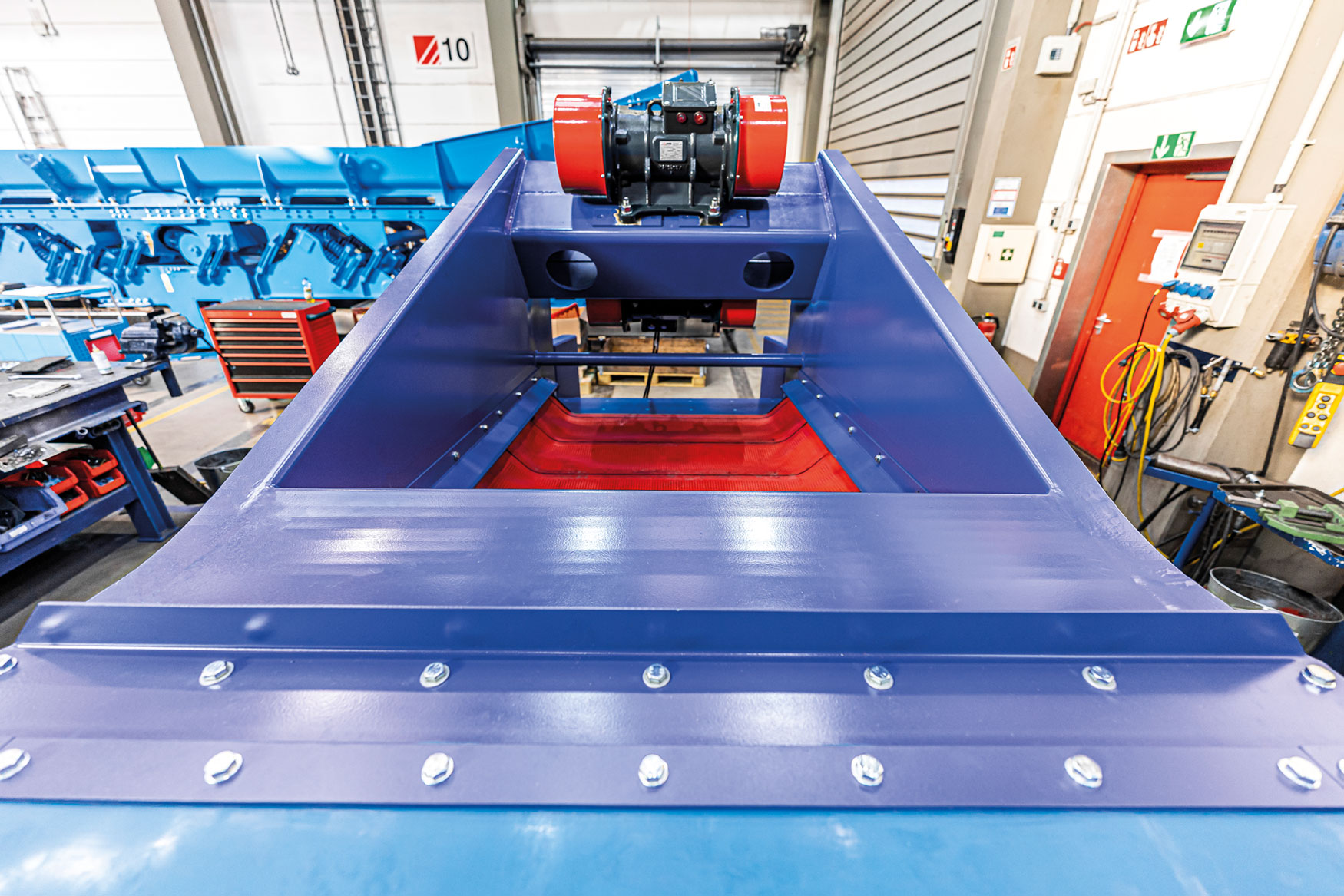

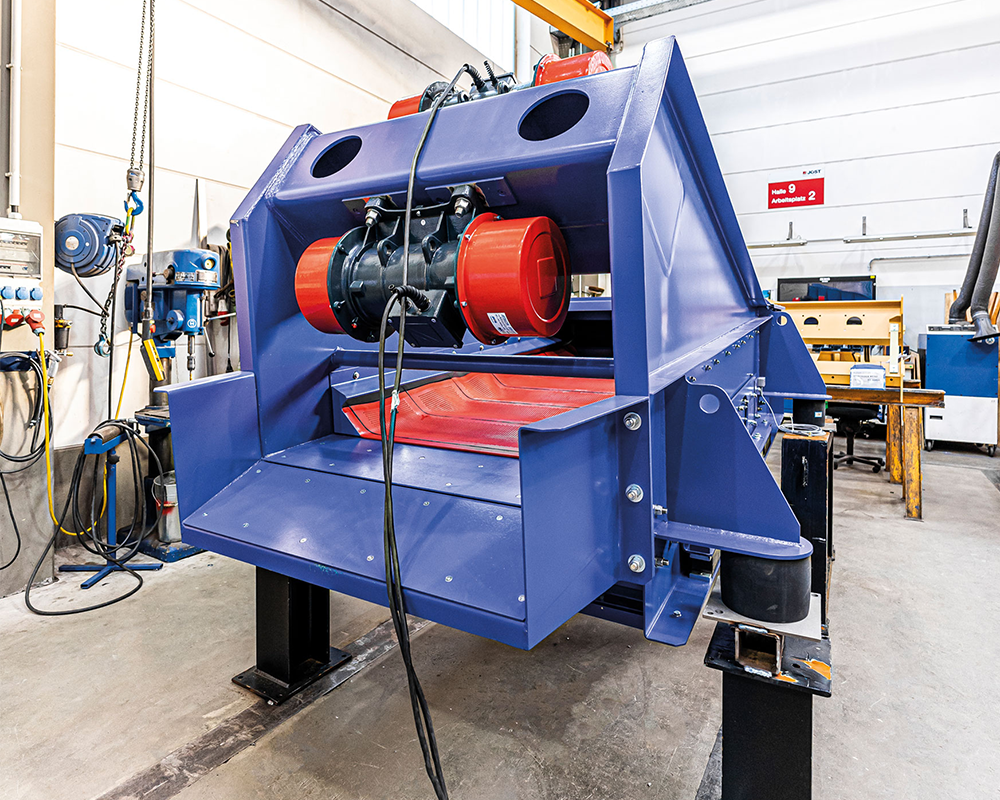

The OSCILLA Compact Flip-Flow Screen is powered by a slider crank drive. In this system, the internal frame is set into motion and the base frame serves as a counterweight. Installing the Vibroblocks at a decline angle adds a vertical component to the screen deck.

This system is typically used when small restoring forces are demanded, limiting the design of the support frame.

The multi deck version allows each deck to be configured individually. In addition to plastics and glass recycling, applications include construction rubble, slag and metal scrap.

Small dynamic restoring forces

Lightweight design

Multi-deck versions with individually configurable screen decks

Wear protection

Maschinenüberwachung

ASR

Demolition Waste

Glass Recycling

Industrial Waste

Metal Scraps

MHW

Plastic

RDF

Shredder Heavy Fraction

Shredder Light Fraction

Slag

WEEE

D E T A I L S

Product Feed up to 1000 mm and Screen Cut up to 300 mm.

The OSCILLA Combi Flip-Flow Screen is a combination of the OSCILLA Classic with any conventional screen deck(s) of choice.

They are used to relieve the load of the Flip-Flow Screen deck with a pre-separation stage or to limit the maximal grain size. Furthermore, an additional separating cut can be implemented that is not suited for a Flip-Flow Screen. To do so, the large grain product must be free flowing.

A particularly effective system is created by combining the OSCILLA with the finger cascade screen TopSpin. Its geometry results in a strong self-cleaning effect, even with heterogeneous materials. Major applications include recycling such as domestic and industrial waste, shredded scraps, slag, plastics, packaging and ASR.

The machines are equipped with shaft drives, just like the OSCILLA Classic. Therefore, they are operated as circular oscillators. The required base amplitude is set for the conventional screen deck, as the OSCILLA Classic can be easily adjusted on its own.

Reduction of plant and processing costs through combination of different screening principles

Choice of the ideal screen according to the feed material

Flexible adjustment of the Flip-Flow Screen deck

Various incline angles to match the feed loads of each screen deck

Choice of grease or oil lubrication

Wear protection and anti-stick coatings

Electronic machine surveillance

Electronic control of oscillation amplitudes (OSCILLA Screen decks)

Air suspension

| 3.300 | 3.960 | 5.300 | 5.940 | 7.260 | 7.920 | |

|---|---|---|---|---|---|---|

| 900 | x | |||||

| 1.200 | x | |||||

| 1.500 | x | x | ||||

| 2.100 | x | x | ||||

| 2.400 | x | x | x |

ASR

Demolition Waste

Industrial Waste

Metal Scraps

MHW

Plastic

Slag

WEEE

D E T A I L S

Product Feed up to 100 mm and Screen Cut up to 40 mm.

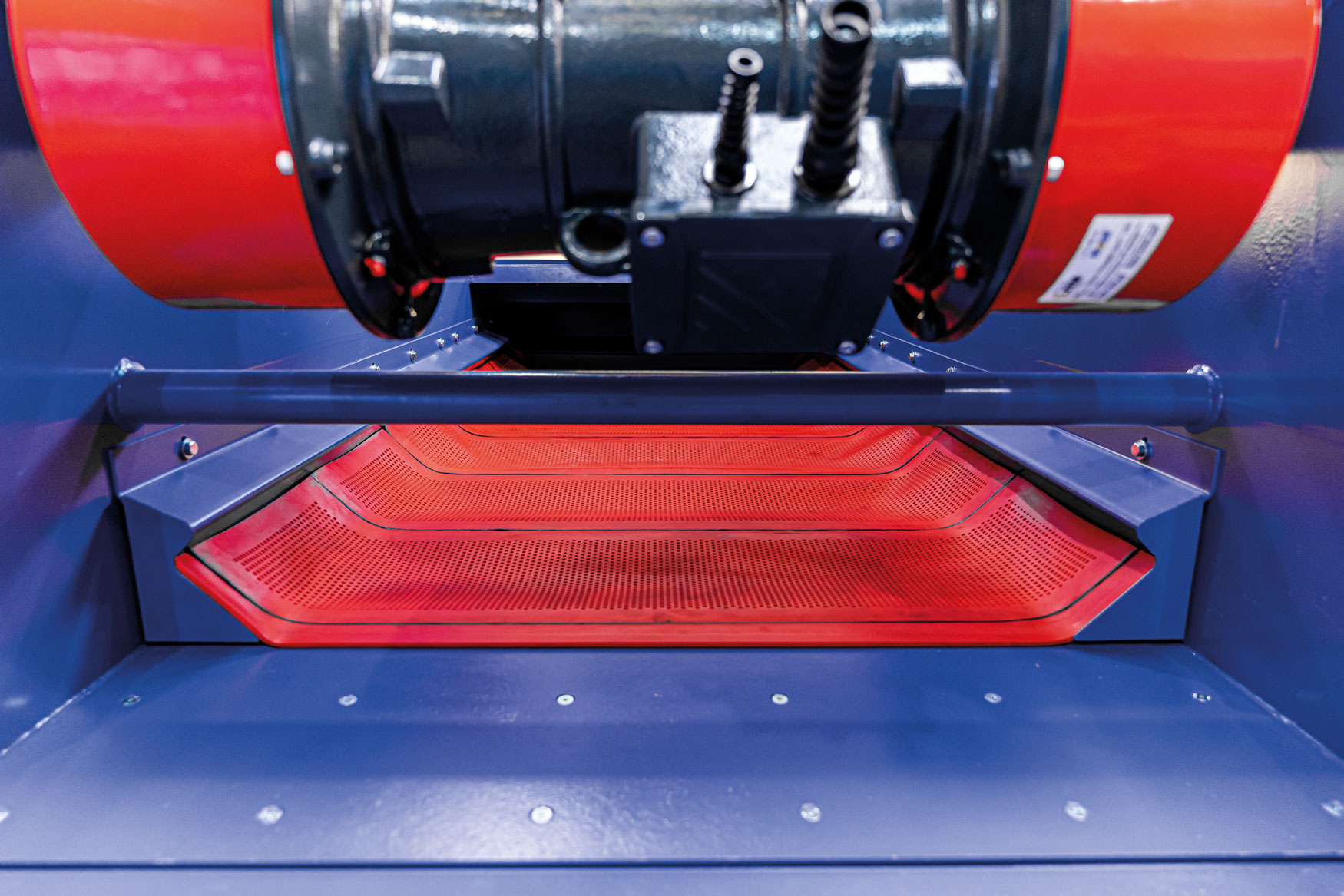

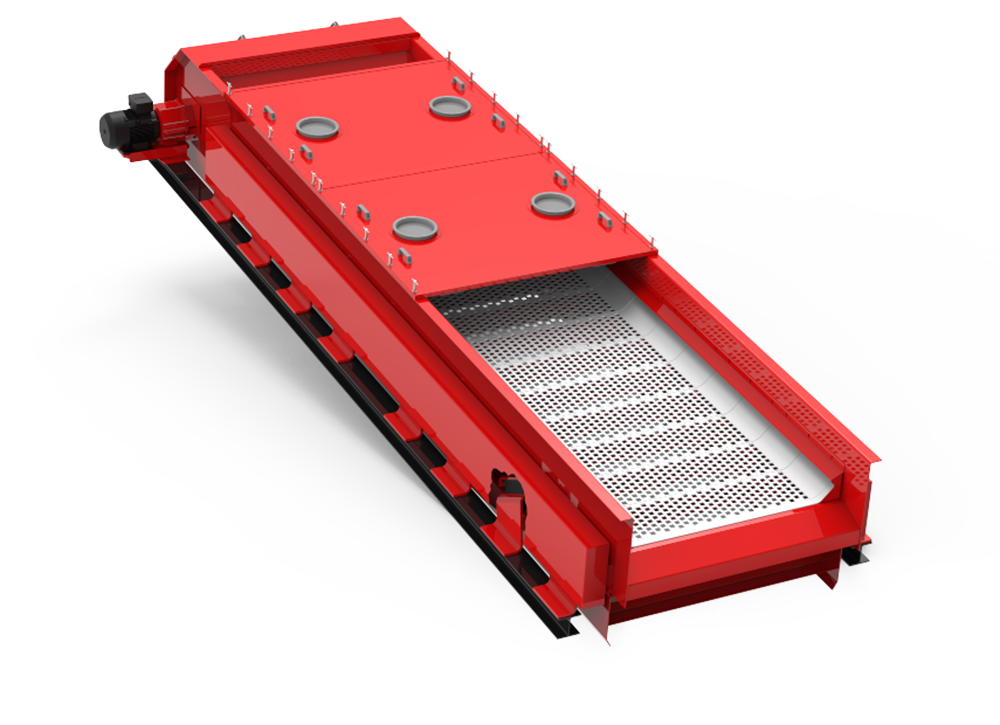

The Flip-Flow Screen OSCILLA Screen-Feed combines a feed unit with an OSCILLA Screen deck. This ensures that down-stream sorting machines can achieve a more efficient and clean separation, even with challenging products.

The product is pre-classified or cleaned at high acceleration rates and is still discharged evenly to the following machine.

The OSCILLA Screen-Feed is driven by the well proven JX unbalanced drives and operates as a linear oscillator. Typical applications include plastics and glass recycling, domestic and industrial waste as well as slag and ASR.

Reduction of plant and processing costs by feeding and screening in one processing step

Increased efficiency of downstream sorting

Small height difference between material feed and discharge

Wear protection and anti-stick coating

Electronic machine surveillance

Centralized fine grain discharge

Discharge adapted to sorting unit

| 1.980 | 2.640 | |

|---|---|---|

| 900 | x | |

| 1.200 | x | |

| 1.500 | x | |

| 2.100 | x |

ASR

Demolition Waste

Glass Recycling

Industrial Waste

Plastic

RDF

Shredder Heavy Fraction

Shredder Light Fraction

Slag