Finger Cascade Screen TopSpin

The Finger Cascade Screen TopSpin has been specially developed for the pre-classification of difficult-to-screen products in recycling plants.

It is used wherever conventional screening systems reach their limits – for example, with fibrous, elongated, or contaminated mixed fractions.

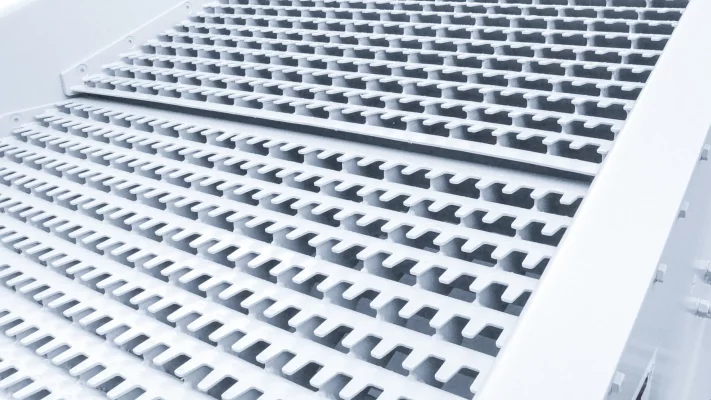

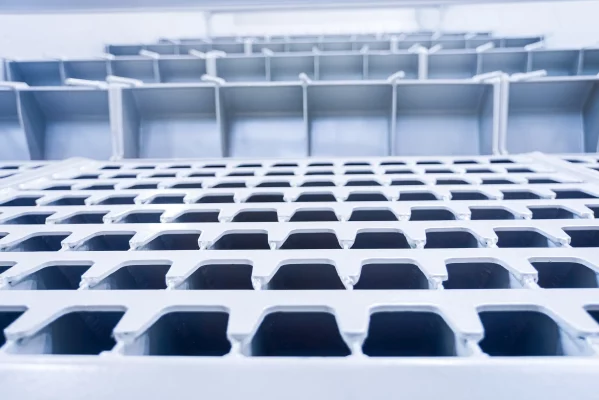

The cascade steps ensure particularly effective product circulation, while the screen surface guarantees high throughput and clog-free screening. While fines are reliably screened out, elongated pieces are specifically discharged via the screen overflow.

The system is based on a circular vibratory screen with shaft drive, achieving above-average acceleration values – ideal for materials such as ASR, shredder residues, RDF, MHW, or waste wood. In combination with optional features such as vibration monitoring, covers, or maintenance platforms, the TopSpin cascade screen offers a reliable and low-maintenance solution for demanding applications.

FUNCTION

The circular vibratory motion is generated by a shaft drive with unbalance system, ensuring uniform material distribution across the screen deck. The material is conveyed over several stages – the so‑called cascades. At each step, the conveying material is deliberately overturned, loosening the product and distributing it evenly over the screen surface.

While fine and small-particle material passes through the screen surface, elongated pieces, contaminants, and oversize particles are discharged over the overflow. This effect makes the cascade screen the ideal solution for difficult-to-screen, fibrous, or inhomogeneous mixed materials, where conventional screening machines tend to clog or lose separation efficiency.

Thanks to the design of the screen surface and the high acceleration values, the screen remains almost clog-free, even in demanding applications. The machines can be adapted to specific requirements in length, width, inclination, and design – ensuring a stable, low-maintenance, and efficient screening process.

OPTIONS

- Various machine widths and lengths

- Optionally single- or multi-deck design

- Screen surfaces also available in special materials

- Covers for dust or splash protection

- Integrated maintenance and inspection openings

- Walk-on platform for maintenance and operation

- Vibration and oscillation monitoring systems

- ATEX-compliant design for use in hazardous areas

- Special designs for specific requirements

Fields of Application

Fields of Application

The JOEST cascade screen is the ideal solution for the pre-classification of difficult-to-screen, inhomogeneous, or elongated materials, which tend to cause clogging or insufficient separation efficiency in conventional screening plants. Thanks to its special design featuring a cascade deck, circular motion, and robust construction, it is particularly well suited for demanding recycling processes with varying material fractions.

Shredder residues (ASR), refuse-derived fuels (EBS, RDF), mixed municipal waste, household waste (MHW), bulky waste, plastics, used tires

mixed scrap, light metal fractions, contaminated construction waste

waste wood, rootstocks, mixed wood with foreign materials

Equipment Options

For optimal adaptation to material, process, and plant environment, the cascade screen offers numerous equipment options – flexibly configurable and proven in practice.

Adjustable Cascade Deck Geometry

The number, shape, and inclination of the cascade steps are designed according to process requirements – for maximum product circulation and reliable separation results.

Single- or Multi-Deck Design

The cascade screen is available as a single- or multi-deck system, depending on the desired separation accuracy, feed material, and available space on site.

Protective Covers

Depending on the environment and material properties, the machine can be equipped with a cover – improving safety and cleanliness.

Integrated Maintenance and Inspection Openings

Generously sized inspection openings facilitate cleaning, inspection, and maintenance – reducing downtime and enabling easy handling.

Walk-On Platform for Maintenance and Operation

A sturdy maintenance platform can optionally be supplied – ensuring safe access to the machine for inspection, cleaning, or adjustment work.

Vibration and Oscillation Monitoring Possible

Sensors can be integrated for process control to monitor machine condition and oscillation behavior in real time and visualize the data.

ATEX-Compliant Version Available on Request

For use in hazardous areas, a certified ATEX version with standardized components is available.

Special Designs Available

Depending on process requirements, the cascade screen can be supplied in stainless steel or with special coatings – e.g. for aggressive media.

Advantages

The cascade screen has been specially developed for the separation of difficult-to-screen materials. Thanks to its circular vibratory motion, open deck geometry, and robust design, it offers an exceptionally clog-free, high-performance, and durable solution – ideal for use in recycling processes with varying material streams.

CLOG-FREE SCREENING FOR ELONGATED PIECES AND MIXED MATERIALS

Thanks to the open cascade deck and product circulation, the machine remains reliably operational even with elongated or inhomogeneous materials.

EFFICIENT SEPARATION OF OVERSIZE PIECES AND CONTAMINANTS

Elongated pieces and coarse components are specifically discharged via the overflow – for a clean, well‑defined material stream.

HIGH SCREENING PERFORMANCE IN A COMPACT DESIGN

With circular vibratory motion and a precisely tuned cascade structure, the machine achieves high throughput rates with minimal footprint.

CUSTOMIZABLE CASCADE DECKS

The number of steps, deck inclination, and screen surfaces can be precisely adapted to product behavior, particle size, and plant requirements.

ROBUST DESIGN FOR CONTINUOUS OPERATION

The cascade screen is designed for demanding processes – ensuring high availability and minimal maintenance effort, even in multi-shift operation.

REDUCED DOWNTIME THROUGH EASY ACCESS

Large inspection openings and easily accessible components enable quick cleaning and straightforward maintenance.

OPTIONAL ATEX VERSION AVAILABLE

For special processes, explosion-protected or corrosion-resistant versions with certified design are available.

IDEAL FOR ASR, RDF, MHW, WASTE WOOD, AND MORE

Thanks to its special design, the cascade screen is ideal for problematic recycling materials with a high proportion of contaminants.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYour Material. Our Test Center.

Before a solution reaches you, it is thoroughly tested in our in‑house test center. Here, we test your materials under real‑life conditions and develop optimal, practical concepts.