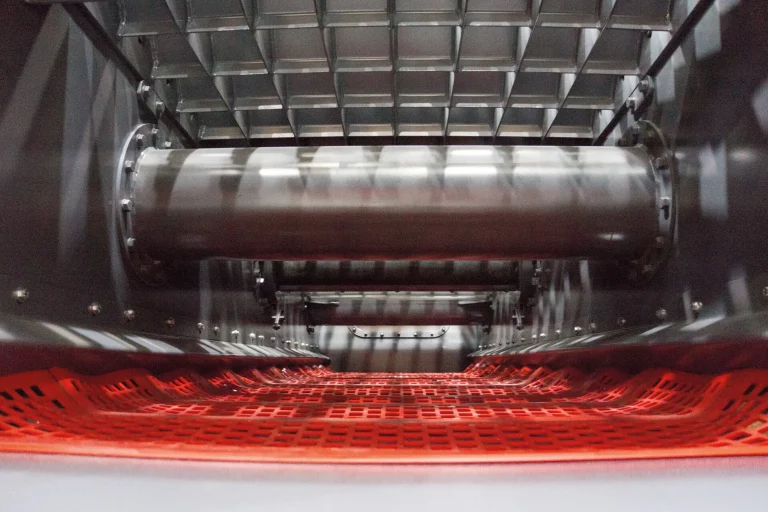

Circular Motion Screens

Circular motion screens from JOEST are proven screening machines for the pre-classification of free-flowing, medium- to coarse-grained bulk materials, for control screening, and for producing high-quality final products.

The circular motion, combined with an individually adjustable inclination angle (typically 10° to 30°), allows for high throughput rates with consistently high separation accuracy – even under demanding operating conditions.

Whether equipped with unbalance motors, shaft drives, or oil-lubricated exciter units, the machines are available in various drive configurations and can be fitted with up to five superimposed screen decks. Depending on the application requirements, different screening surfaces – such as perforated plates, PU decks, or wire mesh – can be selected to achieve the best screening results for the feed material.

Whether in the mining, recycling, or food industry, JOEST circular motion screens stand for robust design, easy maintenance, and high operational reliability in continuous operation.

FUNCTION

Circular motion screens operate on the principle of rotary motion, generated by shaft drives, unbalance motors, or oil-lubricated exciter units.

The screening machine is installed at an inclination angle between 10° and 30°, depending on the application.

The circular motion continuously conveys the bulk material across the screen deck while simultaneously performing effective classification. The material retention time on the screen, as well as material transport, can be precisely influenced via the inclination angle and amplitude.

Depending on the design, the machine can be equipped with up to five screen decks, enabling multi-stage separation of different particle sizes within a single system. The choice of screening surface depends on the requirements – ranging from PU or rubber modular panels to perforated plates or wire mesh.

This machine type is particularly suited for dry, free-flowing bulk materials with medium to coarse grain sizes and is highly effective in preventing pegging.

To keep the screening surface clear even under difficult screening conditions, special tapping devices can be installed beneath the screen meshes. As a rule, JOEST circular motion screens are equipped with a feed deck and, if required, one or more cascade steps to ensure product recirculation.

OPTIONS

- Up to five screen decks possible

- Various drive concepts (unbalance motor, exciter unit, shaft drive)

- Screening surfaces made of PU, rubber, wire mesh, perforated plate, or bar grate

- Dust-tight enclosed machine design

- Reinforced construction for coarse or heavy products

- Inspection openings for easy inspection and maintenance

- Wear linings for highly abrasive materials

- Integrable covers or suction hoods

Fields of Application

JOEST circular motion screens are used wherever medium- to coarse-grained bulk materials need to be classified efficiently – whether for pre-classification, final classification, or protective screening.

Thanks to their robust design and variable configuration, they are ideally suited for high material throughputs, abrasive materials, and demanding environments.

Gravel, crushed stone, sand, natural stone, grit, and broken raw materials

Construction debris, slags, waste glass, metal fractions

Fertilizers, minerals, catalyst carriers

Ores, limestone, quartz sand

Equipment Options

A wide range of equipment options is available to optimally adapt to your requirements. Whether screening media, drive technology, or machine design – JOEST circular motion screens can be individually configured and flexibly integrated into existing processes.

Up to five screen decks possible

Multiple decks allow simultaneous separation of different grain sizes within a single machine – space-saving and efficient in operation.

Various drive concepts available

Depending on the application: unbalance motors, oil-lubricated exciter units, or shaft drives – precisely matched to the conveying material, machine length, and screening capacity.

Flexible screening surfaces for any application

PU panels, rubber linings, wire mesh, perforated plates, or bar grates – all screening media can be adapted to the material characteristics.

Dust-tight design for enclosed operation

Enclosed machine design with optional covers reduces dust emissions and protects both operating personnel and the surrounding environment.

Reinforced design for heavy-duty applications

Special heavy-duty versions with reinforced construction are available for particularly coarse, heavy, or abrasive materials.

Inspection openings for easy maintenance

Generously sized access points facilitate inspection, cleaning, and maintenance – without the need for extensive machine disassembly.

Wear protection for abrasive bulk materials

Replaceable wear linings extend machine service life when handling aggressive, highly abrasive materials.

Suction hoods or protective covers

Integrable on request to minimize dust or as protective covers – individually adapted to the plant environment.

Advantages

JOEST circular motion screens are used worldwide whenever reliable and high-performance screening solutions are required. Whether in ore processing in mining, sorting and recovery in recycling, or demanding processes in the chemical industry – our machines are designed for the specific requirements of each industry. They stand out for their high throughput rates, proven drive technology, and minimal maintenance requirements.

High throughput capacity with consistent screening quality

Circular motion and adjustable inclination angle for high screening performance with consistently reliable separation accuracy.

Robust design for continuous operation

Heavy-duty machine construction with wear-resistant components for abrasive and heavy bulk materials in continuous use.

Flexibly adaptable screening surfaces

PU panels, rubber, wire mesh, bar grate, or perforated plates – the machine can be configured precisely to material properties and particle size.

Multi-deck screening for different particle sizes

Up to five screen decks allow parallel separation of multiple fractions – space-saving, efficient, and economical in operation.

Easy maintenance and good accessibility

Inspection openings, quick-change systems, and robust construction ensure short downtime and low maintenance costs.

Safety & environmental friendliness

Enclosed design with suction hood for dusty materials or sensitive environments – safe and environmentally friendly.

Reliable operation even with coarse materials

Even with irregular or coarse feed material, screening performance remains stable – ideal for pre-screening and coarse separation.

Adjustable stroke and inclination

Vibration parameters can be adapted to changing materials – for optimum performance with consistently high separation accuracy.

Your Material. Our Test Center.

To ensure our solution works reliably for you, we carry out preliminary testing in our in-house technical center. Your materials are tested under practical conditions – creating a concept that matches your exact requirements.