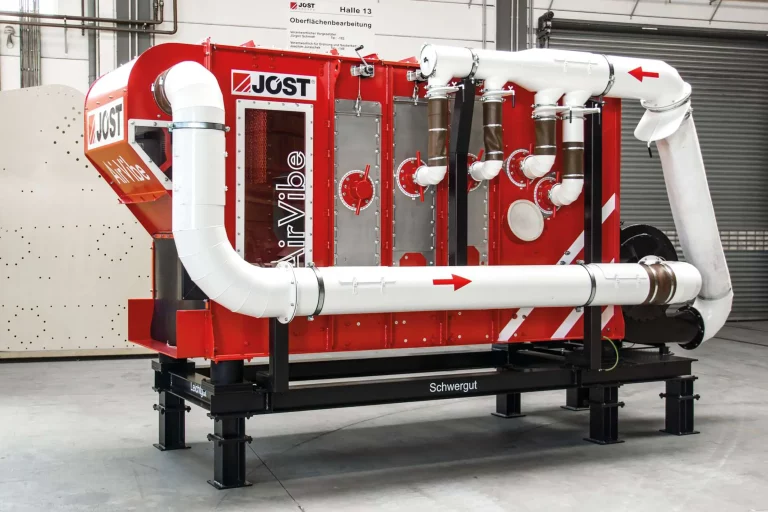

AirVibe Vibratory Air Separator

The JOEST AirVibe is a high-performance sorting system for dry classification of coarse bulk materials up to 300 mm – ideal for demanding recycling processes. By combining cross-flow sifting and ballistic separation, materials are precisely separated by density, shape, and surface – even in heavily contaminated material streams.

The three-stage system reliably separates heavy material, light material, and ultra-light material (e.g. foils or dust) into separate fractions. Thanks to its compact design, modular structure, and optional recirculating air operation, the AirVibe can be flexibly integrated into existing plants.

Typical applications include municipal and commercial waste, construction debris, glass, or RDF. With throughput capacities of up to 15 t/h – especially for glass – the AirVibe offers a low-maintenance, space-saving, and economical solution for modern material stream separation, even without complex filter technology.

FUNCTION

The AirVibe operates with a multi-stage separation principle based on the combination of cross-flow sifting, vibratory conveying, and ballistic separation. The goal is the efficient separation of coarse, dry bulk materials – even with highly fluctuating particle size distribution or material shape – into three main fractions: heavy material, light material, and ultra-light material.

First, the material is conveyed into the separation zone via an accelerated vibrating trough conveyor. During the conveying process, it is singulated by defined edges and transferred into a stable trajectory. A horizontal air stream, introduced from below, strikes the material crosswise to the conveying direction and deflects light particles (e.g. foils, paper, wood residues). These are collected in the light material fraction.

At the same time, the heavy material (e.g. stones, metals, glass) falls into the heavy material discharge in an almost undisturbed parabolic flight path. A third, optional separation stage additionally separates the ultra-light material, i.e. very light, flat, or dusty particles, via a separate outlet.

The separation parameters such as air volume, inclination angle, and throwing distance can be adjusted individually – ideal for changing material properties. The AirVibe can be operated either with fresh air or in recirculating air mode and, in combination with a cyclone, requires no additional filter technology.

The result is a clean, single-grade separation with high process reliability, even with heterogeneous input – ideal for modern recycling plants.

PRODUCT DETAILS

The AirVibe from JOEST is a high-performance dry sorting system for triple separation of coarse bulk materials by density, shape, and aerodynamics – entirely without the use of water or complex filter technology. Designed for particle sizes up to 300 mm, the system is ideal for demanding recycling processes with highly fluctuating material compositions.

The machine combines mechanical conveying via a vibrating trough, cross-flow sifting, and ballistic trajectory separation in a compact housing. The feed material is divided into three fractions:

- Heavy material (e.g. stones, glass, metals)

- Light material (e.g. plastics, wood, paper)

- Ultra-light material (e.g. foils, fluff, dust)

The individual separation parameters such as air volume, inclination, acceleration, or throwing distance can be individually adjusted and matched to the specific material feed. Depending on the variant, the AirVibe is available in various sizes – with throughput rates of up to 15 t/h, e.g. for glass. The system can be operated with fresh air or in recirculating air mode and requires no additional filter technology when connected to a cyclone.

Optional designs include a feed chute, height-adjustable separation zone, automatic adjustment, stainless steel components, ATEX-compliant versions, or integration into complete plants. The compact design, ease of maintenance, and low energy consumption make the AirVibe an economical and reliable solution for modern bulk material classification.

OPTIONS

- Various machine sizes and designs

- Adjustable air volume, inclination, and throwing distance

- Feed chute with variable feed rate control

- Height-adjustable separation zone

- Operation possible with recirculating air or fresh air

- Separation into two or three fractions

- Integration into modular complete plants

- Stainless steel components for sensitive media

- ATEX-compliant version available

- Cyclone or filter connection optional

Applications

The JOEST AirVibe is ideal for dry sorting of coarse, heterogeneous bulk materials where separation by density, shape, and surface property is required – without the use of water, with low energy consumption, and with high separation precision. Thanks to its versatility, the AirVibe is successfully used in a wide range of waste and recyclable material processing applications.

Residual waste, lightweight packaging, bulky waste, composite materials

Masonry, screed, tiles, insulation materials, wood

Hollow glass, flat glass, contaminated glass mixtures

Mixed fractions from household and commercial waste

Equipment Options

To ensure that the AirVibe can be seamlessly integrated into a wide range of processes and material streams, numerous equipment options are available – modular, adaptable, and field-proven.

Different machine sizes and configurations

The AirVibe is available in various performance levels and sizes – depending on the desired throughput, particle size, and plant layout.

Individually adjustable separation parameters

Air volume, inclination angle, and throwing distance can be precisely adapted to the material feed – for maximum separation accuracy with changing material streams.

Feed chute with adjustable material feed

The feed chute ensures even material distribution and allows flexible adjustment of intensity and cycle.

Height-adjustable separation zone for fine tuning

For precise separation, the separation zone height can be adjusted – ideal for varying particle properties.

Operation with fresh air or recirculating air

The AirVibe can be operated with a cyclone in recirculating air mode or with an external fresh air supply – efficient according to process requirements.

Separation into two or three material fractions

Depending on requirements, the AirVibe can be equipped with an additional stage for ultra-light material – for clean, single-grade material discharges.

Easy integration into modular complete plants

Thanks to its compact design, flexible inlet and outlet connections, the AirVibe can be easily integrated into existing lines.

Stainless steel components for sensitive materials

For aggressive, abrasive, or hygienically sensitive products, stainless steel is available for all product-contacting components.

ATEX-compliant design for hazardous areas available

For applications with explosion hazards, a certified ATEX design is available with all necessary safety features.

Prepared for cyclone or filter connection

For dust removal, the AirVibe can be combined with a cyclone or filter unit – without additional space requirements for filter technology.

Advantages

The AirVibe combines cross-flow sifting, vibratory conveying, and ballistic separation into a powerful overall system – without water or complex filter technology. Its compact design, high separation precision, and flexible adaptation to various material streams make it an ideal solution for modern recycling processes.

Efficient dry sorting without water requirement

Separation is carried out purely mechanically with air and motion – without wet processes or additional water treatment.

Triple separation in a compact unit

Heavy material, light material, and ultra-light material are reliably separated – in a small footprint and without complex plant structure.

Easy adjustment to changing materials

All separation parameters such as air volume, throwing distance, or inclination can be individually adjusted – ideal for varying material streams.

High-precision separation even for coarse fractions

Particle sizes up to 300 mm can be safely separated – even for inhomogeneous or difficult-to-sort material mixtures.

Low maintenance thanks to robust technology and recirculating air system

Operation is carried out without moving parts in the material stream – in combination with recirculating air technology, particularly energy-efficient and easy to maintain.

Versatile equipment for every application

Whether feed chute, separation stage adjustment, or stainless steel components – the AirVibe can be precisely adapted to your process requirements.

Perfect integration into existing plant concepts

Thanks to its modular design and flexible connection options, the AirVibe can be easily integrated into existing processing lines.

Suitable for recycling, RDF, glass, construction debris & more

Whether municipal waste, packaging, or mineral fractions – the AirVibe covers a broad range of materials and ensures single-grade outputs.

Your material. Our test center.

In our test center, we simulate real operating conditions to analyze your materials precisely and develop optimal solutions – practical and economical.