SCREW & SMALL METAL FABRICATION INDUSTRY

Automatic feed systems

for welding studs

and flange nuts

JOEST delivers feeding technology to screw technology manufacturer.

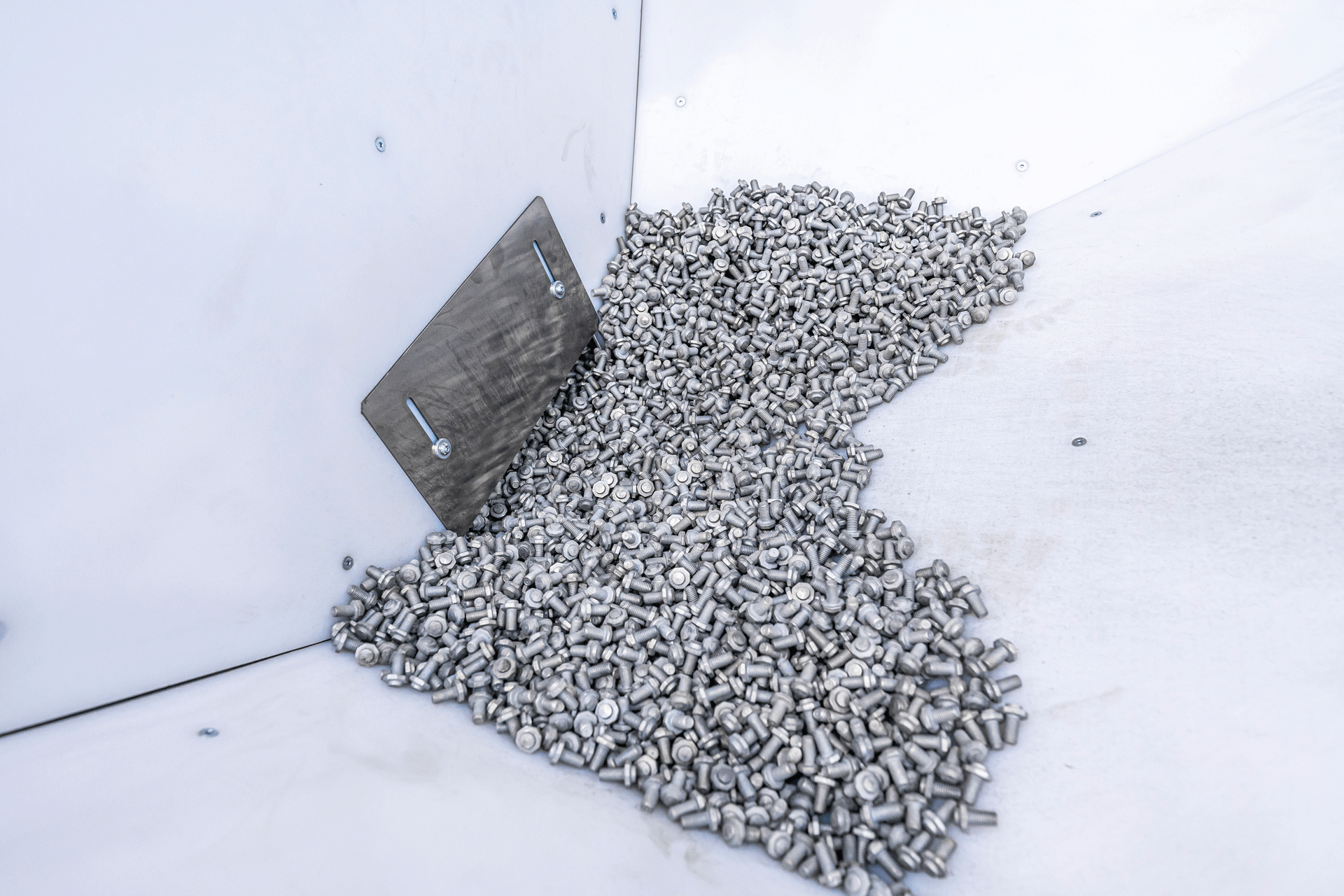

JOEST manufactured two automaticfeed systems to convey, sort and feedwelding studs and flange nuts. Thesystems are built up of an overheadconveyor with a link chain, a storage container, a linear feeder and a workpiece recirculation.

![]()

The workpieces are provided manually in a storage container with an effective volume of 320 liters. The container has a steel design and is lined with PU plates. It also features a filling level indicator. The parts are presorted by workpiece specific carrier rails, conveyed upwards and fed into a linear feeder.

The linear feeder is equipped with two parallel sorting feeders. On these feed-ers, alignment mechanisms force the workpieces into the correct orientation. Excess or falsely orientated parts are rejected by the linear feeder and are recirculated to the storage container. The sorting feeders are equipped with pneumatic deflectors to prevent the magazine from overflowing and to control the feeding lane in case a screw is left out.

At the end of the linear feeder, the workpieces are fed into the existing processing machines in a defined position. The welding studs are discharged to the left and the flange nuts to the right.

After development and manufacturing, the feeding systems were delivered in the fourth quarter of this year. The project was completed to the full satisfaction of all parties and JOEST is looking forward to new exciting projects.

Weitere Beiträge

The Berfus Info Exchange 2024 in Nottuln at the Liebfrauenschule was a complete success for us at JOEST and a great opportunity to get in touch with many committed young people. As an internationally active company, we are always happy to introduce young talents to our diverse training and career opportunities.

The Hey Job Apprentice Bus Tour 2024, which took place on October 10, was a complete success. Pupils from secondary schools in Dülmen had the opportunity to visit a total of 14 local companies on five different routes. The tour was organized by the City of Dülmen’s business development department and offered pupils in the 9th and 10th grades an ideal opportunity to introduce themselves directly to companies and gain an insight into various training occupations.

On 25.09.24, our #JOESTeam was at the “Anschub” training fair at Richard-von-Weizsäcker-Berufskolleg in Lüdinghausen!

We look back on a successful exhibition! The JOEST group was proud to be part of the EUROCAST booth – our Polish representation – at the Metal Expo in Kielce, and we would like to thank everyone who visited us at our stand!