METALLURGY

Conveyor plant for

quality inspection of

aluminum forging parts

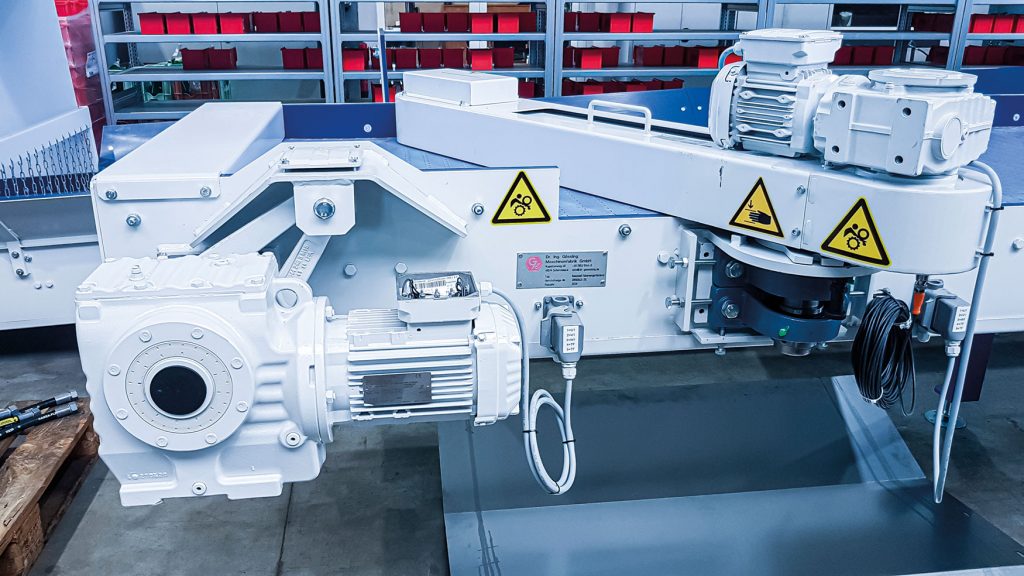

Dr. Goessling designs plastic Hinged Belt Conveyor with special discharge arms.

For a longstanding client with expertise in metal processing, Dr. Goessling Maschinenfabrik GmbH designed a special conveyor plant that allows for aluminum forging parts to be gently conveyed in a circuit. A particular discharge enables employees to manually perform quality inspections in full operation.

The client’s demands were to design a conveyor plant to gently transport aluminum forging parts. One specification was for the plastic Hinged Belt Conveyor to run in a circle and to discharge the parts at multiple arms for manual quality controls. Many years of experience in the development and manufacturing of conveyors of all sorts and the capability to incorporate individual client demands made Dr. Goessling the first choice.

The client’s demands were to design a conveyor plant to gently transport aluminum forging parts. One specification was for the plastic Hinged Belt Conveyor to run in a circle and to discharge the parts at multiple arms for manual quality controls. Many years of experience in the development and manufacturing of conveyors of all sorts and the capability to incorporate individual client demands made Dr. Goessling the first choice.

Four similar plants have already been delivered to the client. The good cooperation, service and quality of the Goessling machines were once again the reason behind the decision to build another conveyor together. Commissioning is scheduled for the end of the year and is performed by Dr. Goessling.

The Dr. Goessling team was once again able to offer an individual design, meeting special demands and reaching full customer satisfaction. Dr. Goessling is looking forward to your application too and is happy to consult.

Weitere Beiträge

As we kick off the new training year, we are excited to welcome eight motivated young talents to our team:

JOEST’s latest MUCKI Tipping Device sets new standards in automated material handling. Specifically designed to feed a tumblast shot blasting machine in forging operations, this robust system ensures a reliable and fully automated process.

In sensitive production environments such as the chemical and food industries, equipment must meet stringent requirements – from cleanability and operational safety to compliance with explosion protection standards.

From October 21 to 24, 2025, it’s that time again: Blechexpo in Stuttgart opens its doors