JOEST

JOEST trainee among the best in Muensterland

We wish to warmly congratulate our trainee Florian Hagedorn, who has successfully completed his apprenticeship as a mechatronics engineer by earning the grade “Very good”. This year, 660 trainees sat their final examination at the Chamber of Industry and Commerce (IHK) of North Westphalia. 56 of the candidates managed to score at least 92 out of 100 possible marks. On November 17, 2016 the top-scoring graduates were invited to the Autohaus Toennemann in Coesfeld, where IHK Vice President Heinrich-Georg Krumme and host Jochen Toennemann jointly presented the certificates and congratulated the young specialists.

Florian Hagedorn started his apprenticeship as a mechatronics engineer on August 1, 2013. In parallel, he is also studying mechanical engineering at the FH Münster (Münster technical college) in Burgsteinfurt. The apprenticeship in mechatronics consists of a combination of mechanics, electrical engineering and computer science. The training content includes: mechanical processing, assembly and disassembly work, creation of technical drawings, wiring work, PLC programming, control engineering as well as pneumatics and hydraulic circuits.

“I deliberately chose to combine my training as a mechatronics engineer with the company JÖST GmbH + Co. KG with st

udying mechanical engineering. The training teaches you a lot of basic knowledge in a practical context. During my studies, these subjects are addressed and given even more depth,” explains Florian Hagedorn.

JOEST recognizes the importance of outstanding individual performance for the overall quality and progress of a com

pany, and we would therefore like to congratulate Mr Hagedorn once again — we are proud to have such a hard-working and committed employee on board.

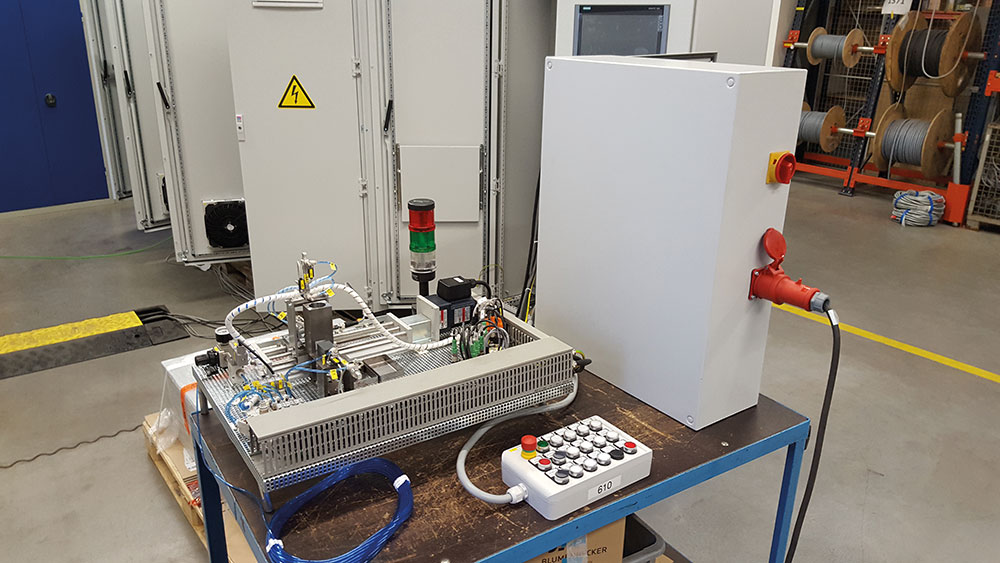

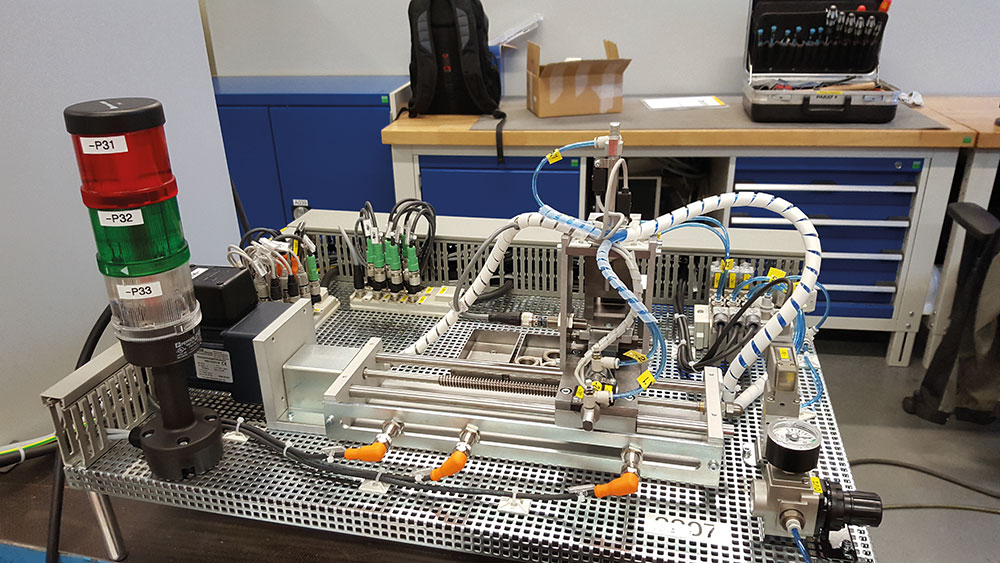

Journeyman’s piece:

Weitere Beiträge

As we kick off the new training year, we are excited to welcome eight motivated young talents to our team:

JOEST’s latest MUCKI Tipping Device sets new standards in automated material handling. Specifically designed to feed a tumblast shot blasting machine in forging operations, this robust system ensures a reliable and fully automated process.

In sensitive production environments such as the chemical and food industries, equipment must meet stringent requirements – from cleanability and operational safety to compliance with explosion protection standards.

From October 21 to 24, 2025, it’s that time again: Blechexpo in Stuttgart opens its doors