STAMPING INDUSTRY

Scrap disposal with

three movable containers

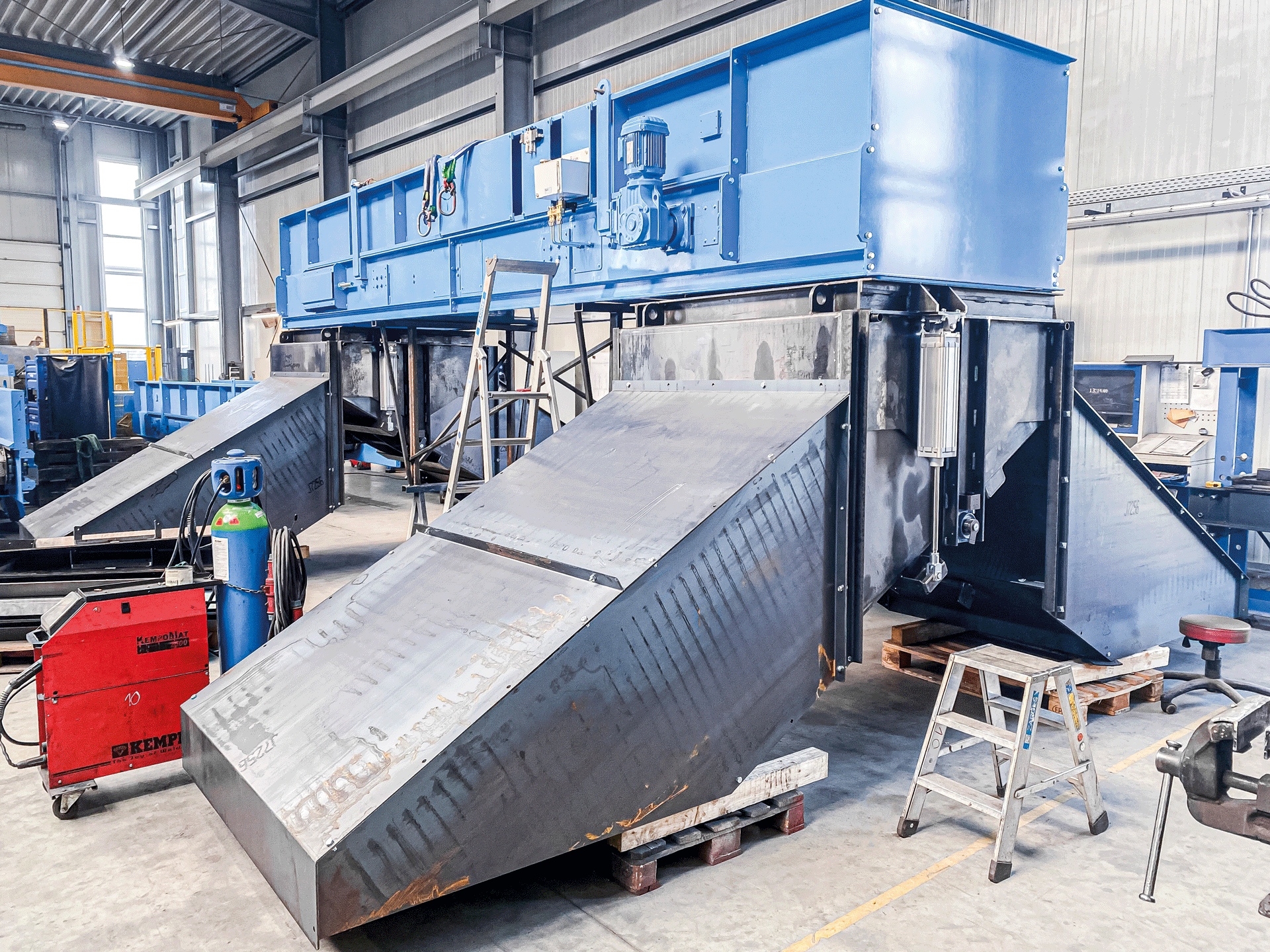

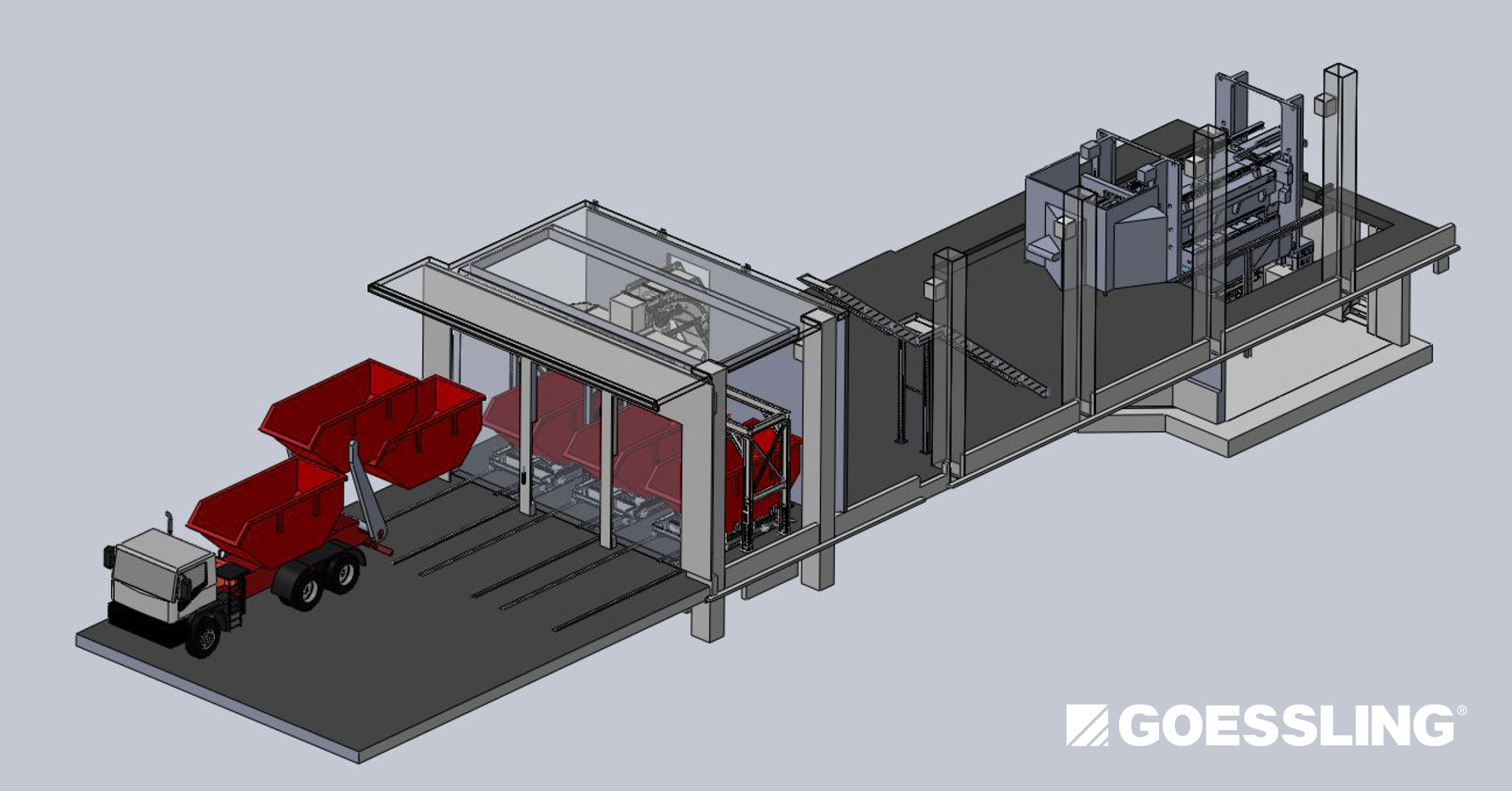

GOESSLING Conveying Technology for stamping scrap in chassis

manufacturing.

![]()

This year in September, the division GOESSLING delivered a customized conveying solution to a long-term client that once again relied on the high quality and positive user experience.

When manufacturing chassis parts, stamping scrap occurs beneath the stamping press. These scrap parts must be disposed in containers. Using their experience in GOESSLING conveying technology, JOEST was able to offer the client a robust solution with excellent service.

The special challenge of this project was that the stamping scrap is charged over a special chute system in the basement onto a Double-Z-Conveyor with an effective width of 625 mm. The scrap is then transferred on a reversible conveyor with the same effective width. At the the transitions, the reversible conveyor has pivoting chutes. The both pivoting slides enable the oily scraps to be distributed into three displaceable containers.

The conveying system, made from aluminum, steel, stainless-steel and galvanized sheet metal is low-maintenance and is delivered in an oil-tight configuration. Stamping scrap can be conveyed at a throughput of four to six tons per hour.

Weitere Beiträge

As we kick off the new training year, we are excited to welcome eight motivated young talents to our team:

JOEST’s latest MUCKI Tipping Device sets new standards in automated material handling. Specifically designed to feed a tumblast shot blasting machine in forging operations, this robust system ensures a reliable and fully automated process.

In sensitive production environments such as the chemical and food industries, equipment must meet stringent requirements – from cleanability and operational safety to compliance with explosion protection standards.

From October 21 to 24, 2025, it’s that time again: Blechexpo in Stuttgart opens its doors