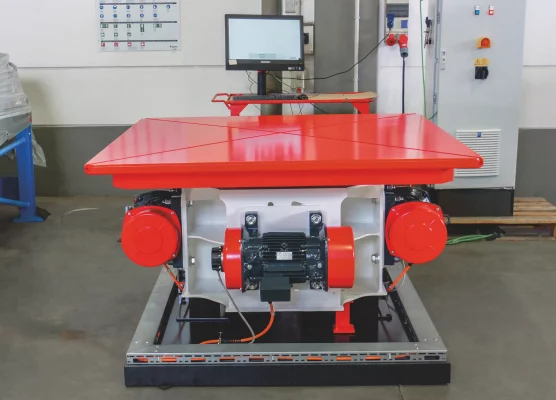

Compaction table

The JOEST compaction table has been specially developed for demanding applications in the lost foam process. It enables complete compaction of binder-free molding sand – even in hard-to-reach, horizontal, and multi-angled cavities of complex patterns. Precisely controllable vibration in three spatial directions ensures targeted filling of all mold areas.

The system features resonance-free start and stop behavior and particularly gentle handling of the product – ensuring consistently high mold quality with minimal scrap.

FUNcTION

Product details

Options

- The control system can also be expanded with features such as recipe management.

Fields of Application

Cold box process, Lost Foam casting process

Equipment Options

Control system versions

Various control system versions are available and can be flexibly adapted to individual process requirements. Depending on the application, the control system can be expanded with features such as recipe management.

Advantages

ADJUSTABLE TABLE SIZES

Flexibly configurable for various plant layouts and mold dimensions.

THREE-AXIS VIBRATION CONTROL

Enables precise sand flow in horizontal and vertical cavities.

RESONANCE-FREE OPERATION

Prevents unwanted effects during process start and stop.

ELECTRONIC FINE-TUNING

Individual adjustment of frequency, amplitude, and vibration direction.

INTEGRABLE CONTROL SYSTEM

Compatible with standard control systems for automated process chains.

Your Material. Our Test Center.

At our in-house technical center, all solutions are tested under realistic conditions before being deployed in series production. We analyze your materials in detail and develop tailored, application-oriented concepts with maximum practical relevance.