Dosing Feeders

Precision meets flexibility – JOEST dosing feeders are the ideal solution for the precise, consistent, and controlled conveying of powders, granulates, and bulk materials. They are used wherever exact dosing quantities and reproducible material distribution are required – whether in the food, chemical, plastics, or packaging industries.

Thanks to their compact design, flexible configurability, and optional integrated cooling or heating, JOEST dosing feeders can be seamlessly integrated into almost any process chain. Each system is tailored to customer-specific requirements – from trough design and surface finish to cleanability and ATEX compliance.

FUNcTION

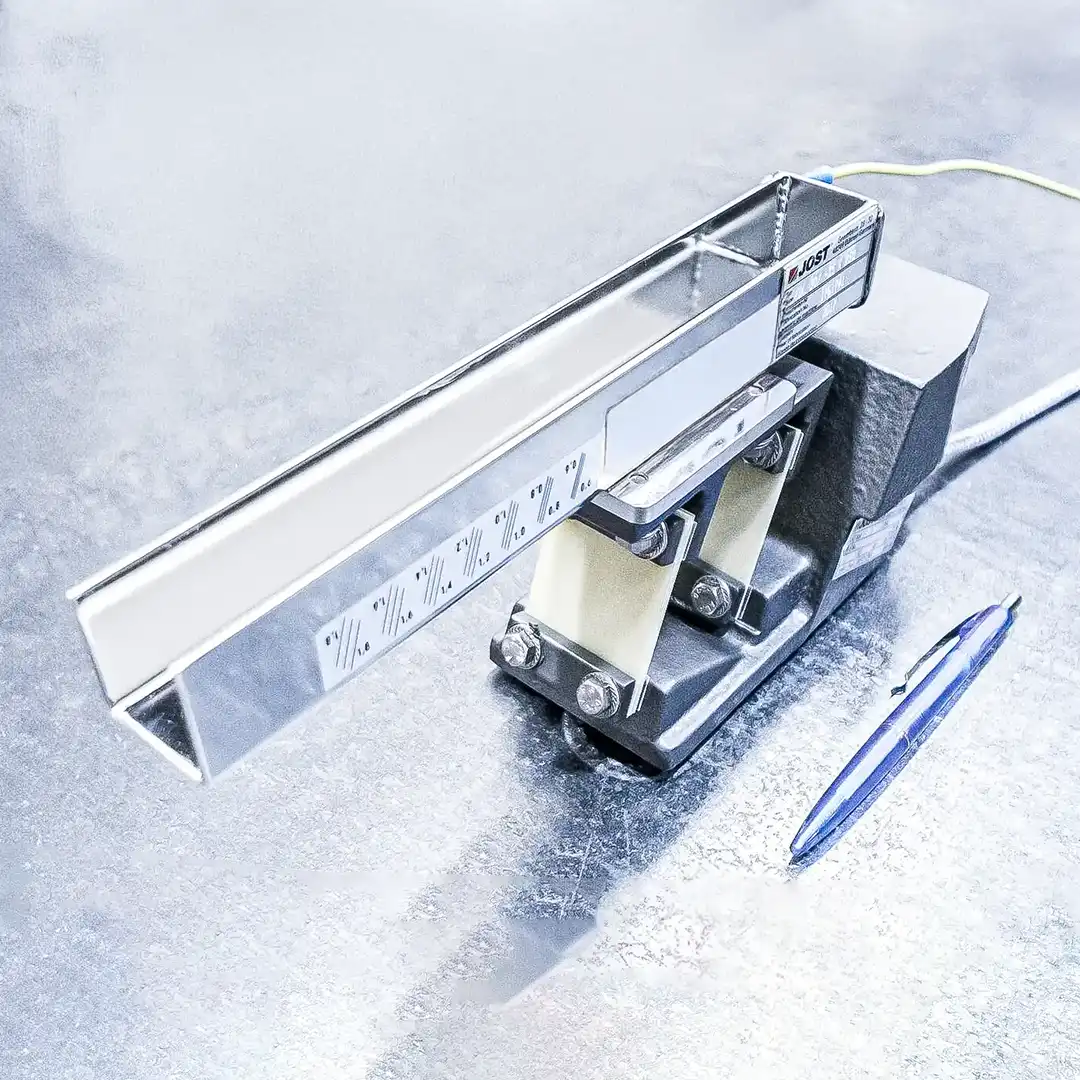

JOEST dosing feeders are based on proven vibratory conveying technology using JD dosing drives. The linear vibrators generate a micro-throw motion that enables particularly gentle and uniform material transport. Dosing is continuously adjustable via amplitude control, allowing for precise regulation of product throughput and residence time in the conveying zone.

Optionally, the feeder trough can be equipped with an integrated heating or cooling system to specifically control the material temperature. Custom air-cooling solutions can also be implemented.

Product details

Our dosing feeders are precision conveying systems that can be adapted to a wide range of applications thanks to their modular design and well-engineered features. The units are based on a robust vibratory conveyor system with linear drives and are specifically designed for metered discharge of powders, granulates, and fine bulk materials.

The feeder troughs are available in various widths and lengths and can be configured as open, covered, or fully enclosed versions depending on the application. For hygienically sensitive or potentially explosive environments, stainless steel and ATEX-compliant versions are available.

A key feature is the option for integrated product cooling or heating: via water-cooled double walls or optionally through process air, the material temperature can be precisely controlled during conveying. This makes the dosing feeders a highly versatile solution for temperature-sensitive processes.

Special equipment such as layer height gates, hopper solutions, cleaning access points, or electropolished surfaces allow adaptation to industry-specific requirements – for example, in the food, chemical, or plastics industries.

Options

Our dosing feeders are available in various sizes and configurations. Optional features include:

- Various trough geometries: rectangular, V-shaped, circular, or trapezoidal

- Heated or cooled feeder trough designs

- Compact substructures – stationary or mobile

- With or without hopper/bin

- Outlet configuration with discharge edge or connection spout

- Trials with your product possible at the JOEST Test Center

- Full enclosures for dust-protected operation

- Hygienic design allowing for complete and contamination-free discharge

- Stainless steel versions with ground or electropolished surfaces

- ATEX-compliant versions for use in potentially explosive atmospheres

- Accessories such as layer height gates for mass flow regulation

Fields of Application

JOEST dosing feeders are used wherever powdered, granulated, or fine-grained materials need to be precisely dosed, separated, or conveyed. They are particularly suitable for continuous or batch processes that require a reliable material flow and adherence to hygienic standards. Thanks to the optional integrated heating or cooling function, even temperature-sensitive products can be handled safely and efficiently – making these dosing feeders ideal for applications in the food, chemical, plastics, and packaging industries.

Spice powders, sugar, grain products, flour, starch, dry goods (e.g. cereals), etc.

Chemical powders, fine chemicals, color pigments, raw materials requiring thermal treatment

Plastic granulates, additives, temperature-sensitive mixtures

Equipment Options

JOEST dosing feeders can be flexibly adapted to individual processes. A wide range of options ensures that each machine is precisely tailored to the conveyed material, operating environment, and specific requirements. Below is an overview of the key equipment features:

Heated or cooled feeder trough design

Double-walled trough elements enable precise temperature control of the material – using water, cooling media, or process air to ensure stable product quality.

Various trough shapes and cross-sections

Trough geometries such as rectangular, V-shaped, or circular allow for optimal adaptation to material properties and conveying direction.

Oscillating or stationary covers

Protects against dust or environmental influences while ensuring easy access for cleaning or maintenance – tailored to your process area.

Hygienic design for easy cleaning

Complete emptying without product contamination, smooth internal surfaces, and optional integrated cleaning water drains support manual or automated cleaning.

ATEX-compliant design for Ex zones

For use in potentially explosive atmospheres, gas- and dust-tight designs are available in compliance with current ATEX directives.

Customizable discharge variants

Whether discharge edge, outlet spout, or flexible sleeve – product discharge can be configured precisely to suit your requirements and plant layout.

Hoppers, bins, and feeding units

Upon request, the feeder can be equipped with integrated hoppers or bins – dust-tight, with level sensors or defined feed control.

Stationary or mobile support structures

Available as a fixed setup or mobile version with rollers or lifting system – ideal for flexible installation sites or easy maintenance access.

Surface treatments & special materials

Electropolished, ground, or coated surfaces are available for enhanced hygiene, chemical resistance, or gentle product handling.

Process reliability through layer height gate

Layer height gates allow regulation of material height in the trough and ensure consistent discharge – especially important for handling sensitive products.

Advantages

JOEST dosing feeders combine precise conveying technology with a high degree of flexibility in design. Thanks to intelligent drive systems, compact construction, and optional temperature control, they offer numerous advantages for a wide range of applications – from exact dosing to thermal product treatment. Below is an overview of their key strengths.

Precise, uniform dosing

Accurate control of feed rate for reproducible processes and minimal product loss.

Continuously adjustable conveying capacity

Amplitude control allows the material flow to be individually adapted to the process.

Thermal product treatment

Integrated cooling or heating functions enable precise temperature control during conveying.

Compact, space-saving design

Ideal for confined installation spaces and easy to integrate into existing production lines.

Hygienic and easy to clean

Smooth surfaces, complete product discharge, and optional integrated cleaning drains.

Low maintenance requirements

Robust drive units and low-maintenance design ensure high operational availability.

Individually configurable

Trough geometry, materials, surfaces, and features are tailored to your specific application.

ATEX-compliant version available

Suitable for use in potentially explosive atmospheres in accordance with applicable directives.