Feeders

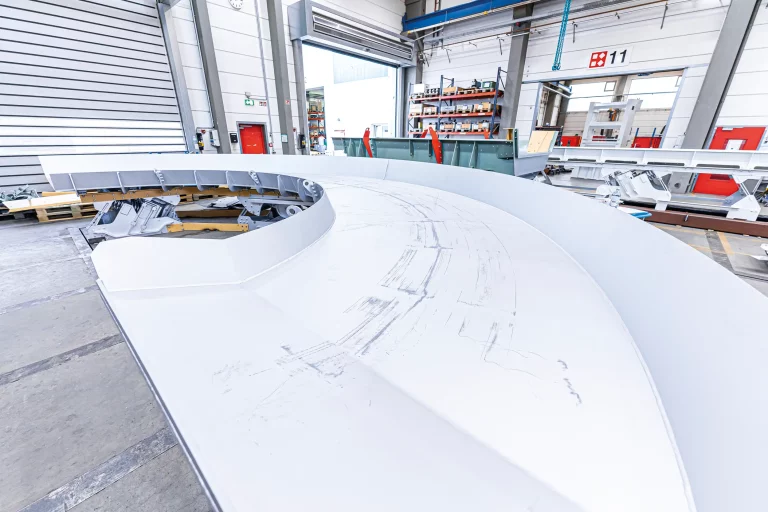

JOEST feeders are reliable and precise conveying systems for a wide variety of bulk and piece materials – from coarse foundry sand to sensitive food products. Whether for continuous material transport, accurate discharge from bunkers, or finely tuned dosing: our trough and tubular feeders are technically advanced, modular in design, and used across a broad range of industries.

Depending on your specific requirements, different drive concepts are available: unbalance motors for high throughput, magnetic drives for precise metering, or resonance systems for energy-efficient long-distance conveying. Whether open or enclosed, made of steel or stainless steel – thanks to their modular design and numerous configuration options, JOEST feeders can be tailored precisely to your application – robust, hygienic, energy-efficient, or all of the above.

FUNcTION

Unbalanced-Driven Systems

Two self-synchronizing unbalance motors generate a linear oscillating motion that moves the material via micro-throw movements. This technology enables high throughput rates and is ideally suited for use in foundries, quarries, recycling plants, or in processing coarse bulk materials.

Magnetic Drives for Dosing Precision

Magnetic feeders offer continuously adjustable amplitude and instantaneous response when starting and stopping – ideal for cyclic processes, batch feeding, or precise dosing into weighing units. Material flow can be accurately controlled and metered.

Resonance Feeders for Long Distances

This technology uses a crank drive to generate vibration, which is transmitted with maximum energy efficiency via a tuned two-mass system. The low dynamic loads on the foundation and quiet operation make these systems especially attractive for long conveying distances or sensitive environments.

Product details

Various feeder systems are available to suit different applications:

- Unbalanced-driven feeders for high conveying capacities and heavy-duty applications

- Magnetically driven feeders for precise metering and immediate response in cyclic operation

- Resonance feeders for particularly energy-efficient transportation over longer distances

- Enclosed tubular feeders for hygienic or potentially explosive environments

JOEST feeders are precisely engineered to match your material properties, operating conditions, and process objectives – available as open or enclosed designs, in steel or stainless steel, and with optional features such as integrated screening sections, trough heating, or bed depth control gates.

Options

Our feeders are available in various sizes and configurations. Custom designs for special requirements are also possible at any time. Optional features include:

- Dust- and gas-tight design (e.g. ATEX)

- Stainless steel versions for hygiene-critical areas

- Welded or bolted wear linings

- Bed depth control gates for mass flow regulation

- Integrated screen sections for residual material separation

Fields of Application

JOEST feeders are used across a wide range of industries – wherever bulk or piece materials need to be conveyed reliably, either continuously or in precise doses. Thanks to adaptable designs and a variety of material options, our systems are suited for a broad spectrum of applications and materials. Their versatility allows JOEST feeders to be precisely tailored to specific material properties and process conditions – from abrasive to hygroscopic, or for dust- and explosion-prone environments.

Wet casting process, cold box process, lost foam process, core sand conveying, sand conveying, used foundry sand conveying, casting transportation, coke transportation, alloying agent transportation, bunker discharge, separation, melting operation

Powders, granulates, sugar, hygiene-critical materials, plastics

ASR (Automotive Shredder Residue), broken glass, industrial waste, scrap metal, plastics, MSW (Municipal Solid Waste), RDF (Refuse-Derived Fuel), WEEE (Waste Electrical and Electronic Equipment), slag, shredder light and heavy fractions

Natural stone, construction debris, ores, minerals, coal, stones

Equipment Options

To ensure every feeder fits your process precisely, JOEST offers a wide range of configuration options and special features – technically refined, field-proven, and individually combinable.

Various Drive Technologies

Depending on the application, unbalanced, magnetic, or resonance drives are available. While unbalanced drives enable high conveying capacities, magnetic drives offer particularly precise metering. Resonance systems stand out for their energy-efficient operation over long conveying distances with minimal dynamic loading.

Open or Closed Design

JOEST feeders are available as open trough-type systems or fully enclosed tubular conveyors. Closed systems offer dust- and gas-tight conveying – ideal for hygiene-sensitive or potentially explosive environments (ATEX).

Material Variants

In addition to standard carbon steel designs, stainless steel versions are available – particularly for the food, chemical, and pharmaceutical industries. Special materials and surface treatments can also be implemented.

Wear Linings

To handle abrasive media, feeders can be equipped with bolted or welded wear plates. This significantly extends service life and reduces maintenance costs.

Bed Depth Control Gates

To regulate material flow, a bed depth control gate can be integrated into the feeder structure. This allows mass flow to be precisely and reliably controlled – especially ahead of downstream screening or weighing systems.

Covers & Hoods

For dust reduction or protection against contamination, feeders can be fitted with stationary or vibrating covers. Special hood solutions for transfer points or interface areas are also available as options.

Trough Heating

For products with high moisture content or a tendency to stick, trough heating systems are available. These prevent material buildup and ensure consistent material flow – especially important for hygroscopic or temperature-sensitive bulk materials.

Screening Sections & Separation Troughs

If needed, screening sections can be integrated into the feeder trough – either partially or completely. This allows fines to be removed or particles to be separated by size – an ideal solution for complex conveying processes.

Transfer Hoods & Chutes

For dust-minimized and controlled transfer of conveyed material to downstream systems, various hood and chute designs are available – custom-tailored in geometry, material, and connection dimensions.

Needle Gates & Dosing Flaps

For applications requiring controlled interruption or precise release of material flow, JOEST offers robust slide gate solutions – ideal for batch feeding or combined conveying and dosing systems.

Mobile or Stationary Design

Feeders can be delivered as stationary units or with mobile substructures. This allows flexible deployment – e.g., for cleaning, maintenance, or changing process lines.

Custom Connection Solutions

Whether with inlet nozzles, flange connections, or flexible transfer sleeves – all interfaces are manufactured exactly according to customer specifications. This ensures seamless integration into existing processes at any time.

Custom Dimensions

Custom sizes are available – from compact units to large-scale systems. Magnetically driven feeders are typically available with widths up to 2 m and lengths up to approx. 5 m. Resonance feeders can be built with lengths of up to 60 m, depending on the application.

Advantages

Our feeders combine technical precision with high operational flexibility. The combination of robust mechanical engineering, intelligent drive concepts, and individually configurable options makes them the ideal solution for a wide range of conveying tasks – from simple bunker discharge to hygiene-sensitive processes.

High Conveying and Discharge Capacity

Reliable material transportation even with large volumes, challenging grain sizes, or abrasive products.

Precise Control and Dosing

Accurate regulation of material flow for cyclic operation, scale feeding, or continuous processes.

Custom Design According to Requirements

Adaptation to material behavior, bunker pressure, grain size, moisture, and other process parameters.

Flexible Designs and Drive Concepts

Unbalanced, magnetic, and resonance drives available – in open or enclosed configurations.

Durable and Low-Maintenance Operation

Robust construction, wear-resistant linings, and easy maintenance for long service life.

Energy-Efficient at High Performance

Efficient drives with minimal dynamic loading – ideal for energy-optimized processes.

Noise-Reduced System Design

Vibration-optimized construction with optional sandwich trough for quiet operation.

Dust- and Gas-Tight Design Possible

Encapsulated tubular conveyors for hygienic or explosion-prone applications in accordance with ATEX.

Hygienic and Easy to Clean

Quick access for cleaning and inspection – especially important during product changeovers.

Expandable with Additional Functions

Numerous options such as screening sections, heating, or mobile versions can be individually combined.

Self-Clearing Bridge Formation in the Hopper

Vibrations often dissolve material bridges in the hopper automatically.

Your Material. Our Test Center.

Before a solution reaches you, it is thoroughly tested in our in-house technical center. Here, we test your materials under real-world conditions and develop optimal, practical concepts tailored to your needs.