OSCILLA Flip‑Flow Screen Family

When screening challenging, sticky, or inhomogeneous bulk materials, conventional screening machines often cannot meet the requirements. This is where the OSCILLA Flip‑Flow Screens from JOEST come into play: They operate with minimal risk of clogging, loosen the material, and enable efficient fines separation – even under the most demanding conditions.

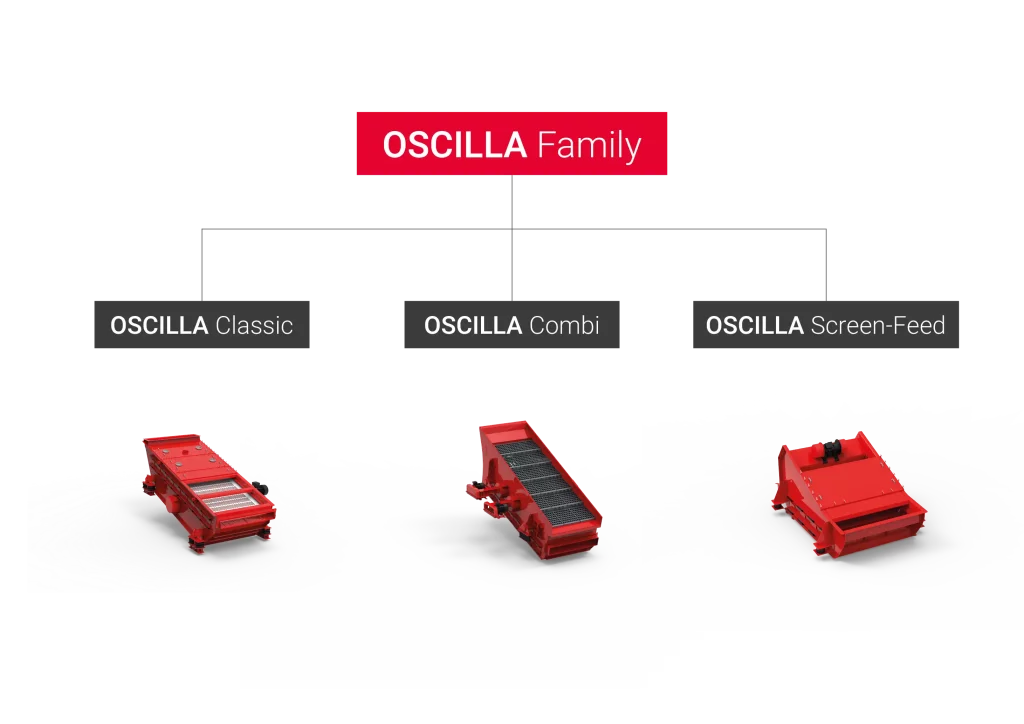

The systems are available in various configurations: from the classic Flip‑Flow Screen to the combined version with an additional conventional screen deck, and the specially developed Screen‑Feed Unit. Typical screen cuts range from 0.5 mm to 40 mm.

With acceleration values of up to 50 g on the screen deck, engineered resonance drive technology, and flexible PU screen mats, OSCILLA screens deliver high separation accuracy with minimal maintenance – for example, through clog‑free operation, even with difficult products and high throughput rates.

FUNCTION

The JOEST OSCILLA Flip‑Flow Screens operate on a resonance system in which the inner screen frame, in reaction to the directly excited outer screen box, is set into relative motion. This relative movement forms the basis for the excitement of the machine’s main frame. Flexible polyurethane screen mats, each attached on one side to the main frame and the screen frame, are alternately tensioned and relaxed. This enables acceleration values of up to 50 g on the screen deck to be achieved.

The newly designed rubber shear springs, in combination with aluminum crossbars , enable greater stroke amplitudes and higher acceleration forces than conventional flip‑flow screens. This design also allows for multi‑deck configurations combining a flip‑flow deck with a conventional screening deck on top without difficulty. Depending on the application and requirements, all common screen deck systems can be used – from wire mesh and perforated plates to rod decks or modular PU systems.

PRODUCT DETAILS

The OSCILLA Flip‑Flow Screens have been specially developed to meet the requirements of classifying difficult‑to‑screen, moist, or inhomogeneous bulk materials. A distinctive feature is the use of flexible screen mats clamped between fixed supports, moving at high frequency under resonance conditions. This motion enables efficient screening without clogging, even when handling challenging feed materials.

Vibration is generated by unbalanced motors or exciters integrated into a two‑mass system. The main mass (machine body) remains largely at rest, while the flexible screen mats operate at accelerations of up to 50 g. Material transport takes place via a slow, linear motion of the machine carrier – resulting in material conveying with simultaneous screening.

OSCILLA screens are available in various configurations:

- Classic version – for pure fine‑grain screening

- Combi version – with additional coarse screen deck (linear)

- Screen‑Feed version – with integrated pre‑acceleration stage for improved material distribution

The machines are designed for cut sizes from 0.5 mm to approx. 40 mm and can be equipped with different PU screen mats or special deck coverings. The modular design allows for easy exchange of screening surfaces and flexible adaptation to different product characteristics or process requirements.

Variants are also available with dust‑tight enclosures, stainless steel components, or ATEX‑compliant designs. These machines are particularly low‑maintenance and, thanks to their compact, low‑vibration design, offer quiet, durable, and efficient operation – even with high throughput rates and demanding materials.

OPTIONS

- Single‑ or multi‑deck design (Classic, Combi, Screen‑Feed)

- Selectable drive systems (unbalanced motor or exciter)

- Various screen deck coverings (PU mats, special meshes)

- Interchangeable screen modules for easy maintenance

- Optional coarse screening stage with linear motion (Combi)

- Screen‑Feed pre‑acceleration module for optimized material distribution

- Dust‑tight enclosure with aspiration option

- Stainless steel design for hygienic or corrosive applications

- ATEX‑compliant design for use in potentially explosive areas

- Integrated process visualization and control

Fields of Application

OSCILLA Flip‑Flow Screens are used wherever conventional screening machines reach their limits – especially when handling difficult‑to‑screen, inhomogeneous, or moist bulk materials. The high acceleration of the screen mats, combined with their self‑cleaning action, makes them the ideal solution for demanding screening processes with high separation accuracy and minimal risk of clogging.

Biomass, compost, refuse‑derived fuels (RDF), commercial waste

Screened sand, crushed sand, clay‑stone mixtures

Dolomite, alumina, ores, slags

Equipment Options

Thanks to their modular design and intelligent system components, OSCILLA Flip‑Flow Screens can be individually adapted to the product, process, and installation situation. A wide range of equipment options allows precise tuning to feed rate, screening task, and ambient conditions.

Single‑ or Multi‑Deck Design

Depending on the screening task, available as a single‑deck version or combined with an additional coarse screen deck – flexible for fine and coarse separation.

Selectable Drive System by Application

Unbalanced motor or exciter provides the required vibration energy – matched to machine size, product, and desired screening frequency.

Various Screen Deck Coverings and Mats

Flexible PU mats or special meshes can be precisely adapted to the screening task – for durable, clog‑free screening even under high loads.

Interchangeable Screen Modules for Easy Maintenance

The screen mats are modular in design and can be changed quickly and without special tools – ideal when switching between products or replacing worn parts.

Integrated Coarse Screen Deck (Combi Version)

A pre‑mounted linear coarse screen deck enables pre‑screening of coarse materials – for greater efficiency and reduced load on the main screen deck.

Dust‑Tight Enclosure with Aspiration

To reduce emissions, the machine can be completely enclosed – including connections for external dust extraction systems.

Stainless Steel Version for Sensitive Processes

For applications in the food, chemical, or pharmaceutical industries, a hygienic stainless steel version with smooth surfaces is available.

ATEX‑Compliant Machines for Hazardous Areas

On request, versions in compliance with ATEX guidelines are available for use in potentially explosive areas, featuring certified components.

Integration of Control and Visualization

The machines can be equipped with modern control technology, including touch panel and process monitoring – for safe operation.

OSCILLA Flip‑Flow Screen Family

The OSCILLA Flip‑Flow Screens have been specifically developed for demanding screening applications where conventional machines reach their limits. By combining high‑frequency vibration, flexible screen mats, and modular design, they offer numerous benefits – especially when handling difficult‑to‑screen, moist, or highly inhomogeneous materials. Their self‑cleaning action, low maintenance requirements, and high separation accuracy make them a powerful and reliable solution for continuous operation.

EFFECTIVE SCREENING OF DIFFICULT MATERIALS

Flexible screen mats with high natural frequency reliably classify even moist, sticky, or fibrous materials without clogging.

HIGH ACCELERATION AT THE SCREEN DECK (UP TO 50 G)

Special flip‑flow technology generates extreme vibrations at the screen deck – ideal for fine cuts and high screening performance with fine fractions.

SELF‑CLEANING SCREENING ACTION WITHOUT AIDS

The high‑frequency movement of the screen mats prevents material build‑up – without the need for knocking devices or external cleaning systems.

COMBINABLE WITH COARSE SCREENING STAGE (COMBI VERSION)

A pre‑mounted linear coarse screen deck enables the removal of larger particles and relieves the downstream fine screening stage.

OPTIMAL MATERIAL DISTRIBUTION (SCREEN‑FEED MODULE)

An optional pre‑acceleration deck distributes material evenly across the screening surface – ensuring optimal utilization of the screen width and consistent throughput.

MODULAR DESIGN WITH INTERCHANGEABLE SCREEN MATS

Screen mats are built in modules, can be changed without tools, and allow for quick adaptation to different materials.

LOW‑MAINTENANCE AND ROBUST DESIGN

Thanks to compact resonance technology, low inherent vibration, and robust steel frames, the machines are durable and easy to maintain.

ADAPTABLE TO PROCESS, PRODUCT, AND ENVIRONMENT

Whether ATEX, stainless steel, dust protection, or integrated controls – OSCILLA screens can be precisely configured to meet industry‑specific requirements.

Our Flip‑Flow Screens at a Glance

OSCILLA Classic

For products with a grain size of up to 100 mm and fractions up to 40 mm.

In the OSCILLA Classic Flip‑Flow Screen, the main frame is set into a circular motion. This motion excites the inner frame, creating a superimposed vibration. This additional vibration applies extra acceleration to the product and supports material transport. Even if the screen deck is overloaded, it will automatically clear itself again. The inclination can be reduced to as little as 10 degrees.

The drive unit of the Flip‑Flow Screen is available in either grease‑ or oil‑lubricated versions.

Application areas of the OSCILLA Classic range from plastics, household and commercial waste, shredder residue, and compost to natural stone, ores, other minerals, and coal.

OSCILLA Combi

For products with a grain size of up to 1000 mm and fractions up to 300 mm.

The OSCILLA Combi Flip‑Flow Screen combines the flexible flip‑flow screen deck of the OSCILLA Classic with conventional screen decks. This combination helps to relieve the flip‑flow deck when handling larger cut sizes, limit the maximum particle size, or achieve additional crosscuts that the flip‑flow deck alone is not suitable for – provided the material is free‑flowing in coarse fractions.

A cascade finger deck, such as the TopSpin finger cascade screen, is often used in this configuration, offering excellent self‑cleaning performance with heterogeneous materials. Typical applications can be found in the processing of recycling materials such as household and commercial waste, shredder residue, incinerator bottom ash, plastics, packaging waste, or ASR. As with the OSCILLA Classic, the drive is shaft‑mounted, causing the machine to operate in a circular motion.

OSCILLA Screen-Feed

For products with a grain size of up to 100 mm and fractions up to 40 mm.

In the OSCILLA Screen‑Feed Flip‑Flow Screen, a feeding unit is combined with an OSCILLA screen deck to ensure that downstream sorting equipment operates more efficiently and with higher purity – even when handling difficult products.

The products are either pre‑classified or cleaned at high acceleration and still transferred evenly to the next processing stage at the machine’s discharge point.

The OSCILLA Screen‑Feed is driven by proven JX unbalanced motors and operates as a linear motion screen. Typical applications include plastics and glass recycling, household and commercial waste, as well as plastics processing, incinerator bottom ash, and ASR materials.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYour Material. Our Test Center.

At our in‑house test center, we subject our solutions to extensive testing before they go into practical use. Your materials are tested under realistic conditions – providing the basis for customized, field‑proven concepts tailored precisely to your requirements.