J-Flow Air Seperator

FUNcTION

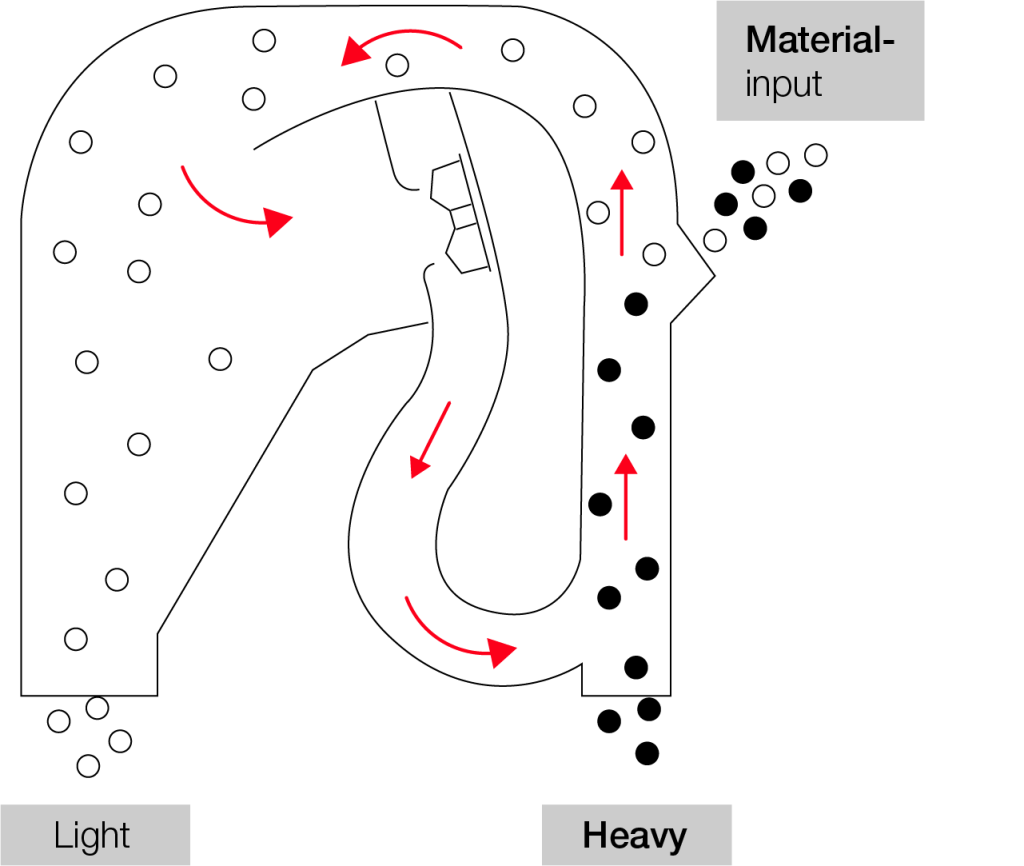

The JOEST J-Flow operates based on the principle of gravity separation in a recirculating air system. It has been specifically developed for the reliable removal of light contaminants from bulk materials—such as non-ferrous metal fractions from ASR like Zorba (non-ferrous metals), ICW (cable fractions), Zurik (stainless steel), or Platinums.

Material typically enters the separation chamber via an integrated vibrating feeder. Inside the chamber, an upward-flowing air stream interacts with the falling material. Due to differences in density, shape, size, and surface properties, light particles are carried upwards, while heavy particles pass through the airflow and fall downward.

The airflow is generated by up to four parallel-connected integrated fan units and circulates within a closed loop. The separated light fraction is conveyed into the expansion separator, where it is discharged separately. The cleaned main fraction exits at the bottom of the separator or is directly transferred for further processing—such as to an eddy current separator or sensor-based sorting system in SHF plants.

Thanks to its compact, enclosed design, the J-Flow is particularly space-saving, energy-efficient, and low-maintenance. The system is delivered with a control cabinet including a frequency converter, allowing for precise adjustment of the air volume flow—enabling optimal tuning of the separation process to the specific material characteristics.

Technical Data

| Type | Working width in mm | Dimensions B x L x H in m | Throughput in t/h | Airflow in m³/h | Weight in kg | Power in kW |

|---|---|---|---|---|---|---|

| J-Flow 450 * | 450 | 0,6 x 2,0 x 1,9 | 1,5 up to 3 | 6.000 | 1 x 4,5 | |

| J-Flow 900 | 900 | 1,2 x 2,0 x 1,9 | 3 up to 6 | 12.000 | 850 | 2 x 4,5 |

| Feeder 800/-200×1600 | 800 | 1,5 x 2,0 x 1,0 | 3 up to 6 | 650 | 2 x 0,95 | |

| OSCILLA Screen-Feed 900×1980 | 900 | 1,7 x 3,3 x 1,7 | 3 up to 6 | 1.600 | 2 x 1,6 | |

| J-Flow 1350 * | 1.350 | 1,6 x 2,0 x 1,9 | 4,5 up to 9 | 18.000 | 3 x 4,5 | |

| Feeder 1250/-200×1600 * | 1.250 | 1,7 x 1,6 x 0,9 | 4,5 up to 9 | 2 | ||

| OSCILLA Screen-Feed 1200×1980 | 1.200 | 2,0 x 3,4 x 1,8 | 4,5 up to 9 | 1.900 | 2 x 2,5 | |

| J-Flow 1800 | 1.800 | 2,1 x 2,0 x 1,9 | 6 up to 12 | 24.000 | 1.300 | 4 x 4,5 |

| Feeder 1700/-200×1800 | 1.700 | 2,0 (2,4) x 2,1 x 1,0 | 6 up to 12 | 800 | 2 x 0,95 | |

| OSCILLA Screen-Feed 1500×1980 | 1.500 | 2,0 (2,4) x 3,4 x 1,8 | 6 up to 12 | 2.100 | 2 x 2,5 |

*Coming soon.

All table data are approximate values.

Options

- Vibrating feeder trough for uniform material feeding and product distribution across the entire screening width

- Replacement of the vibrating feeder trough with OSCILLA ScreenFeed for feed materials with upstream fines separation

- Discharge chutes with extraction ports for dust-free discharge

- Various machine sizes available

- 50 mm channel extension included in scope of supply for bulky products

Fields of Application

ASR (Automotive Shredder Residue) for post-cleaning of metal fractions, SHF (Shredder Heavy Fraction), SLF (Shredder Light Fraction), ICW (Insulated Copper Wire), PCBs (Printed Circuit Boards), WEEE (shredded small electrical and electronic equipment)

For the separation of light contaminants such as fluff, films, textiles, or foam materials

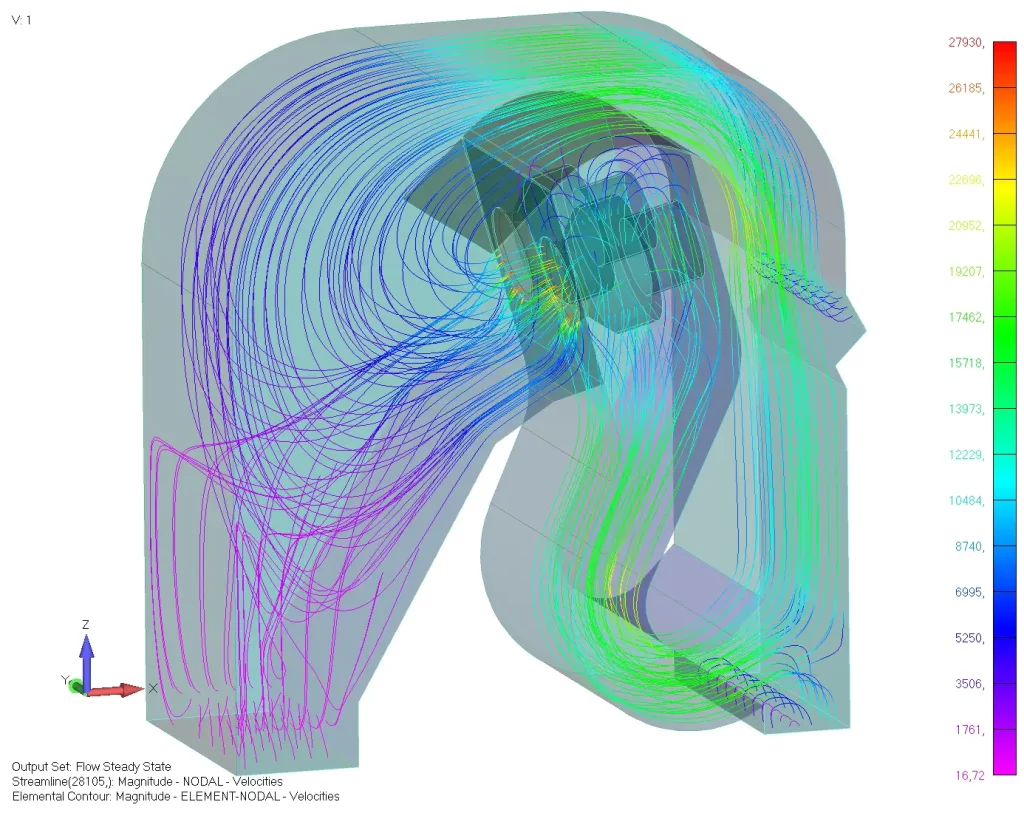

As an example project for one of the largest metal recyclers in the USA, we set out to develop a compact air separator for straightforward applications. To achieve this, we thoroughly analyzed the entire process and all key parameters, and developed intelligent new features. Using in-house flow simulations, we optimized the separation efficiency in the separation channel and expansion chamber, guiding the airflow in such a way that material build-up inside the machine is effectively prevented.

Equipment Options

To optimally adapt the J-Flow to different material streams and process conditions, a wide range of equipment options is available – modular, precise, and proven in practice.

Different machine sizes and performance levels

Depending on throughput and material properties, various machine sizes are available – ideal for new installations or integration into existing plants.

Vibrating trough for material feeding

For uniform feeding and product distribution across the entire working width, the J-Flow can optionally be equipped with a vibrating feeder trough.

OSCILLA ScreenFeed as material feed system

If the feed material contains a high proportion of fines, our OSCILLA ScreenFeed can be used to separate fines via tension rod screening. Even in this setup, uniform feeding and product distribution across the full width are ensured.

Adjustable air volume

The air flow can be precisely adjusted – enabling optimal separation accuracy with varying material compositions. A control cabinet with frequency converter is included as standard.

Integrated recirculating air system with fans

The machine operates in a closed-loop air system with up to four parallel fans – efficient, compact, and requiring no additional space for external filters.

Can be combined with screening, sorting, and separation systems

The J-Flow can be flexibly connected to upstream or downstream systems – ideal for modular plant concepts in the recycling industry.

For dusty materials

For dusty materials, the J-Flow can be equipped with discharge chutes including extraction ports for dust-free discharge.

Advantages

The J-Flow was specifically developed for compact separation of light materials in metal-containing material streams. With high separation precision, a maintenance-friendly design, and precisely adjustable airflow, it offers a cost-effective and reliable solution for demanding recycling processes – efficient, robust, and easy to integrate.

EFFICIENT LIGHT MATERIAL SEPARATION

Reliable separation of fluff, textiles, or films from metal-containing fractions – even with highly variable input materials.

COMPACT DESIGN FOR FLEXIBLE INTEGRATION

The J-Flow requires minimal space and can be easily integrated into existing processing lines – also ideal as a retrofit solution.

RECIRCULATING AIR OPERATION WITHOUT ADDITIONAL FILTER TECHNOLOGY

Thanks to the recirculating air system, no external filter unit is required – saving space, energy, and maintenance effort.

EASY ADJUSTMENT OF SEPARATION PARAMETERS

The air volume is adjustable – ensuring consistent separation accuracy with changing materials.

IDEAL AS A PRE-STAGE FOR OPTICAL SORTERS

Perfectly prepares material streams for eddy current or sensor-based systems – by removing light contaminants.

LOW-MAINTENANCE DESIGN WITH ROBUST TECHNOLOGY

No moving parts in the material stream and wear-resistant construction – ideal for continuous operation under harsh conditions.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information