J-SEN 4.0

The J‑SEN 4.0 Vibration Sensor is our innovative solution for monitoring and analyzing vibrations on machines and equipment. A unidirectional measurement combined with intelligent signal evaluation enables reliable condition monitoring of vibrating machines.

The robust and compact sensor can be easily integrated into existing systems thanks to its flexible interface options – helping to detect wear and damage at an early stage and minimize unplanned downtime.

FUNCTION

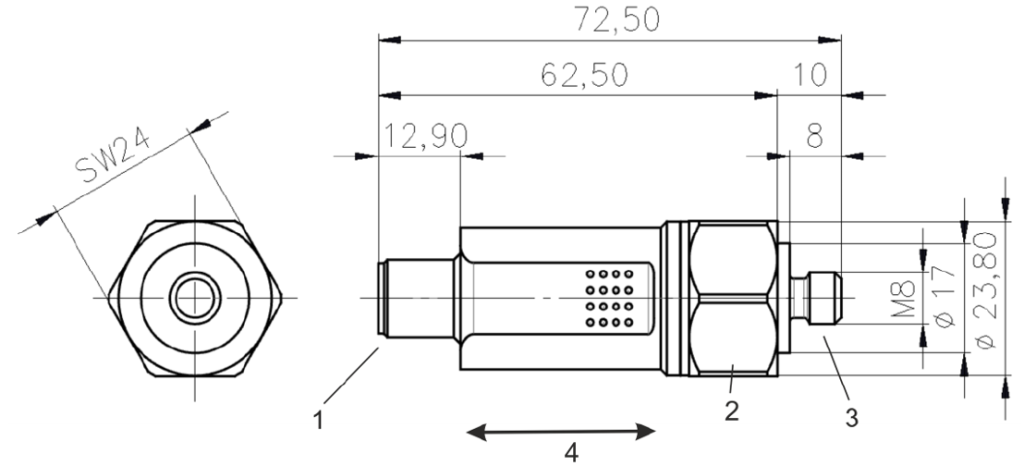

- Compact design with integrated evaluation unit – ready for direct installation on the vibrating machine

- Multifunctional sensor for simultaneous measurement of amplitude, frequency, and acceleration

- Integrated temperature sensor for monitoring operating temperature

- Internal signal processing and data transmission to higher-level control systems

PRODUCT DETAILS

Configurable Interface

Output 1: IO-Link (standard)

Output 2: Analog output 4–20 mA (standard)Analog output scaling: Vibration amplitude 0–40 mm (standard)

Scope of Delivery

Sensor incl. 5 m, 4-pin M12 connection cable

To operate or connect the IO-Link interface, an IO-Link master is required. The master is not included in the scope of delivery. If not already available on site, it can be offered separately upon request.

TECHNICAL DATA

Output signal: IO‑Link (IEC 61131‑9)

Analog output: 4–20 mA (scaled for vibration amplitude 0–40 mm)

Supply voltage: 18–30 VDC

Vibration frequency: 5–100 Hz

Vibration amplitude: 0–40 mm

Acceleration: max. ±15 g

Temperature range: –40 °C to +80 °C

Protection class: IP 66/67

Certifications: CE / UL

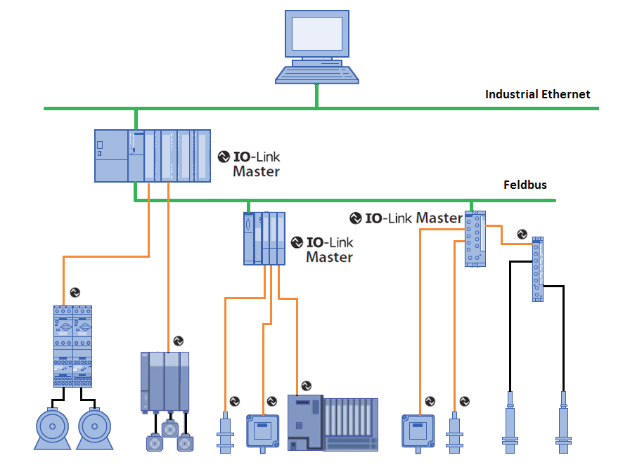

IO-Link Master

The J‑SEN 4.0 uses IO-Link – a globally established communication standard for reliable point-to-point connection between sensor and control system. Sensor parameters are individually configurable via IO-Link – this requires an IO-Link master.

To integrate the sensor into higher-level systems, a dedicated IODD (IO Device Description) is available. It contains all relevant sensor information and is specifically adapted to the J‑SEN 4.0.

Data exchange takes place both cyclically, in the form of configurable process data, and acyclically, for example for maintenance and diagnostic data. This ensures continuous monitoring and seamless integration of the sensor into modern automation environments.

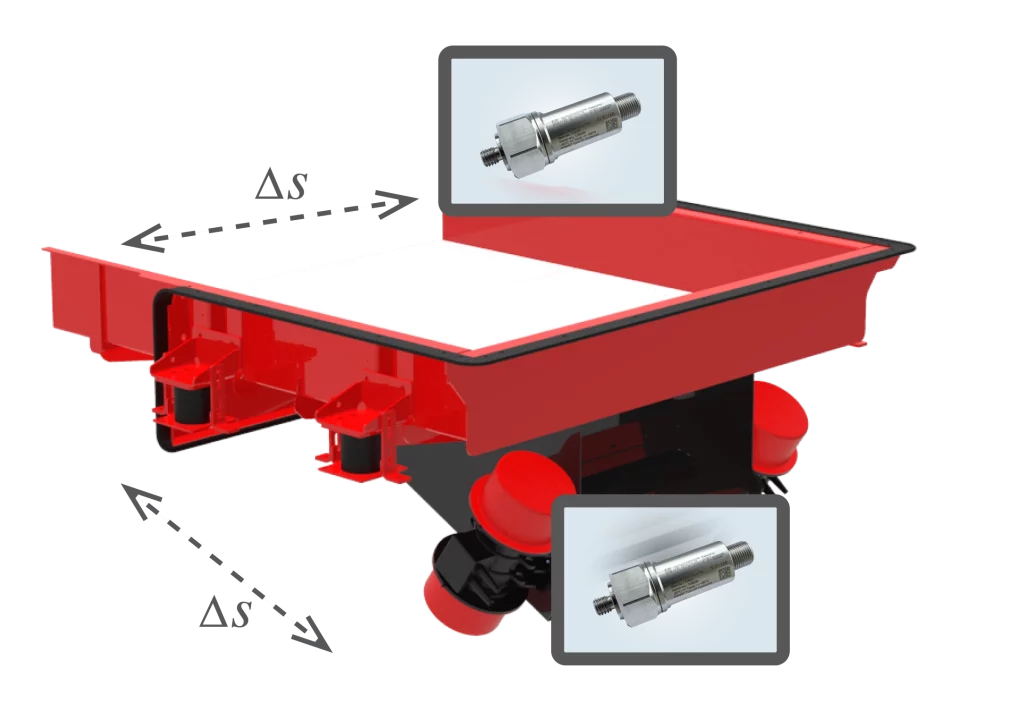

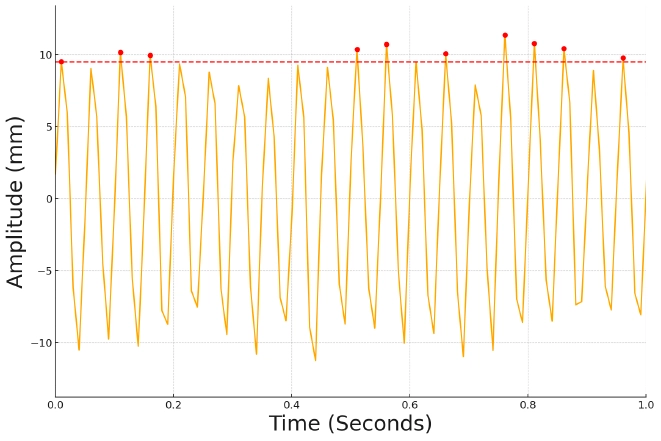

Stroke Monitoring

The J‑SEN 4.0 enables continuous monitoring of the vibration amplitude and delivers an output signal as soon as a defined threshold is exceeded. The system is suitable for detecting standstill conditions and is compatible with all types of vibrating machines.

Additionally, the J‑SEN 4.0 allows for multiple measurements – for example, simultaneously in longitudinal and transverse directions – to gain a comprehensive picture of vibration behavior.

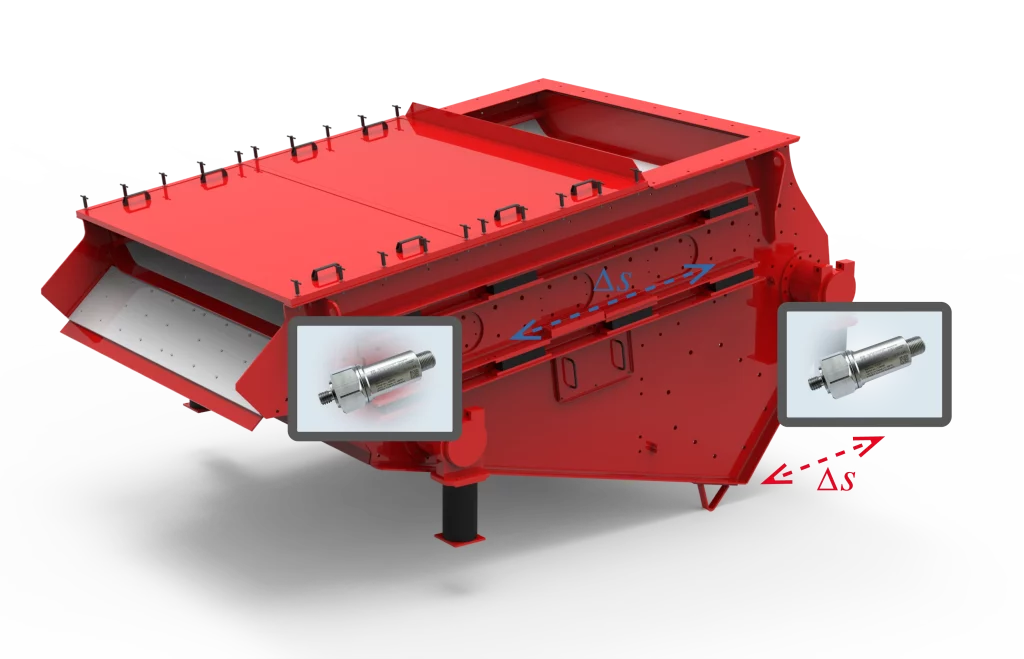

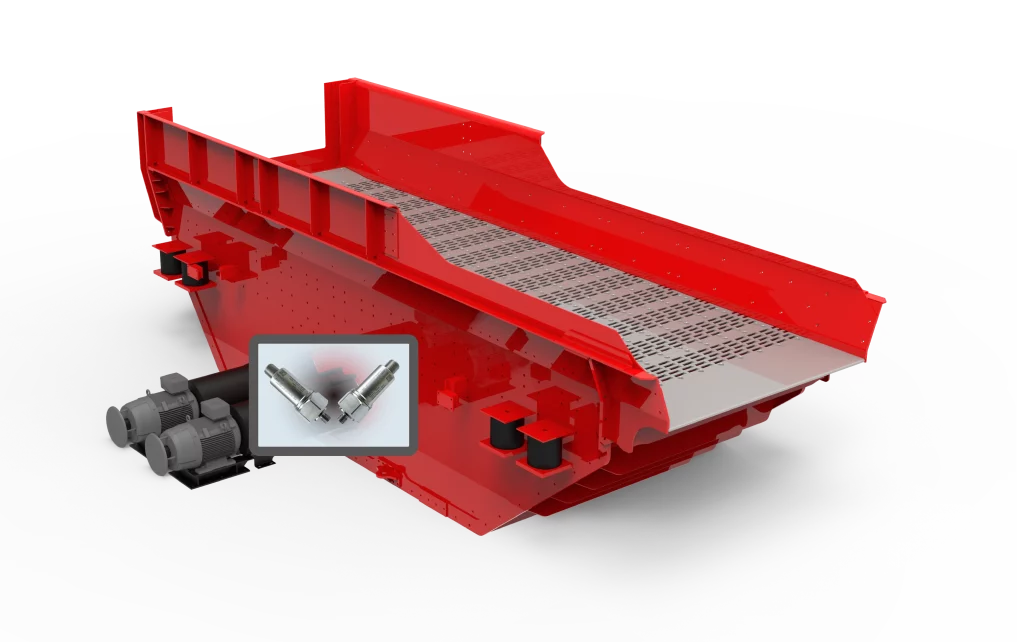

OSCILLA Family – Spannwell Screens

For the OSCILLA Family Spannwell Screens, two J‑SEN 4.0 sensors are used to independently record the stroke of the inner and outer frame. By precisely measuring both components, the relative motion between the frames can be calculated with high accuracy. This enables a detailed analysis of motion dynamics and supports reliable condition monitoring of the machine.

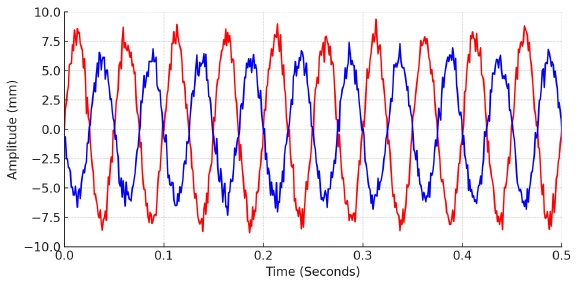

Circular Motion Screen

In circular motion screens, two J‑SEN 4.0 sensors capture the circular motion with precision. This dual measurement enables accurate analysis of vibration parameters and supports both optimization of the screening process and condition monitoring of the machine.

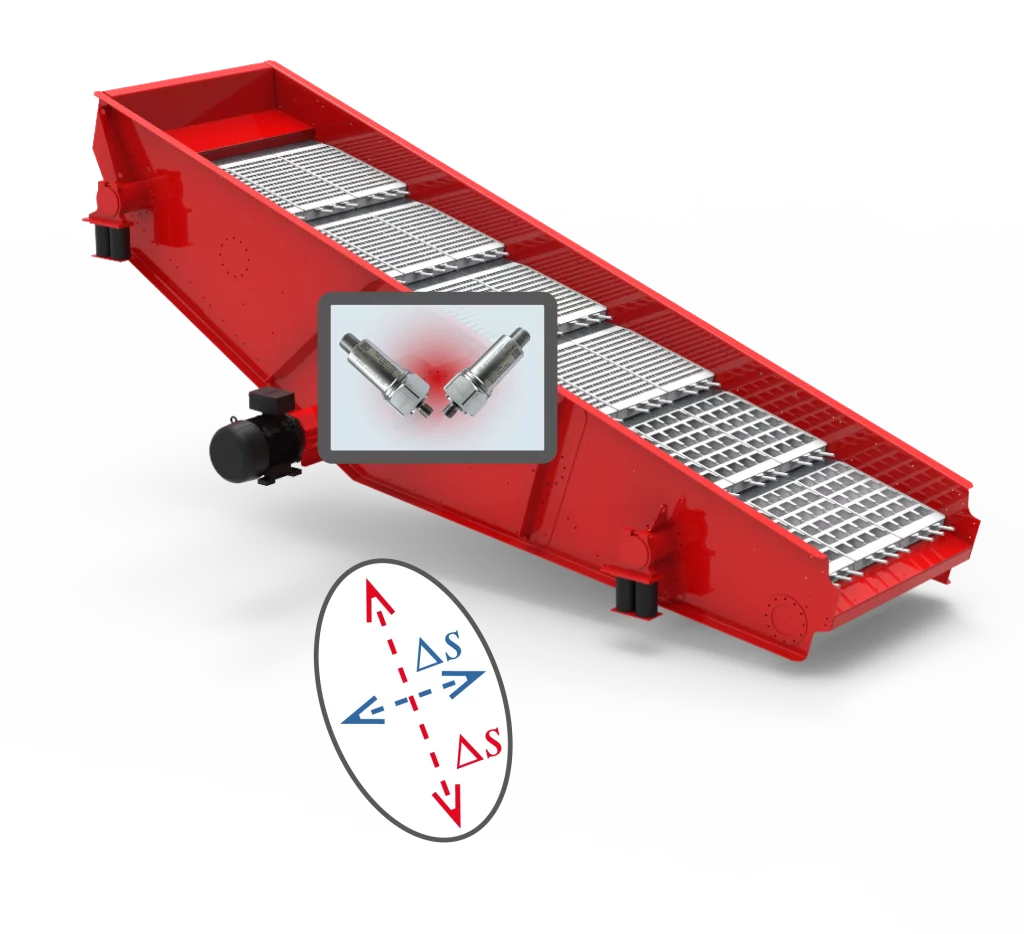

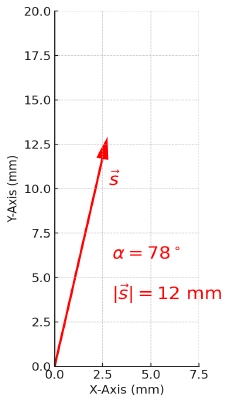

Separation Trough with Adjustable Vibration Angle

Two J‑SEN 4.0 sensors are mounted at a 90° angle to precisely measure the inclination angle of the separation trough.

Continuous measurement and accurate calculation of the angle allow the vibration behavior to be monitored, analyzed, and optimized specifically for the separation process.

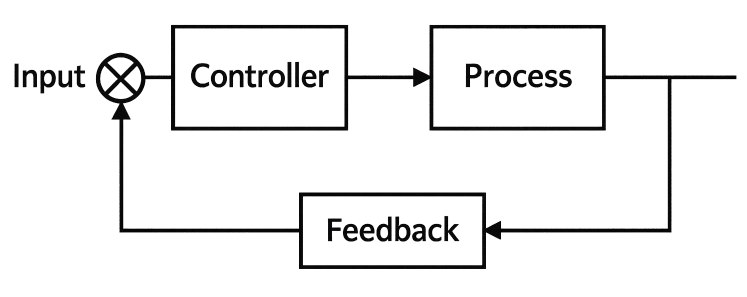

Control of Resonance Conveyors

By implementing a closed-loop control system, the operation of a resonance conveyor can be actively regulated. The J‑SEN 4.0 functions as a feedback sensor to continuously monitor the actual vibration amplitude.

Based on this feedback, the drive power can be automatically adjusted – ensuring maximum process stability and energy efficiency.