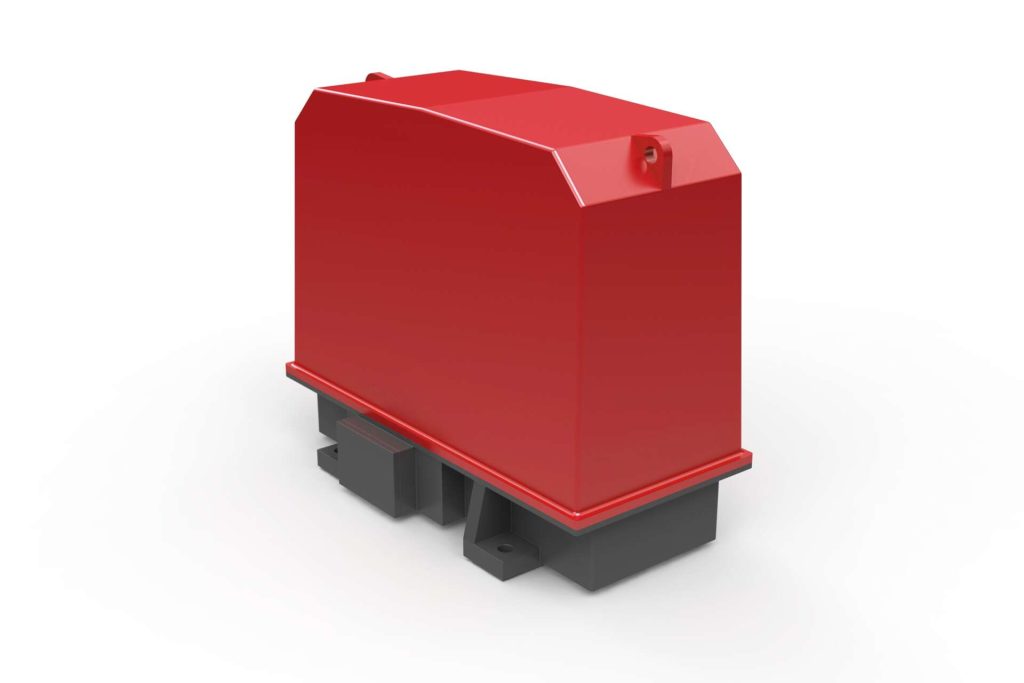

JVM® Magnetic Drives

JOEST MS magnetic drives are electromagnetic linear drives specifically designed to power vibratory feeders, troughs and other vibration-based conveying systems. They stand out for their compact design, high reliability, and completely maintenance-free operation – making them ideal for continuous duty in demanding industrial environments.

With precise vibration generation and flexible control options, material flow and conveying performance can be accurately adapted to specific process requirements.

FUNCTION

Applications

MS magnetic drives are used wherever bulk materials need to be conveyed, metered, or fed in a controlled manner – from food processing and the chemical and plastics industries to metalworking and recycling applications.

Technical Data

Two Vibration Frequency Ranges

Two frequency ranges (25/50 Hz and 30/60 Hz) allow optimal adjustment to different conveying processes and material properties.

Flexible Power Supply

Load Capacities up to 1,300 kg

The drives are designed for high load capacities and enable reliable operation even with heavy troughs or feeders.

Continuous Duty (100% Duty Cycle – S1)

Designed for uninterrupted continuous operation – ideal for ongoing production processes.

Dust and Water Jet Protection

Protection class IP65 according to EN 60529

Dust-tight and protected against water jets – suitable for reliable use even in harsh industrial environments.

Explosion-Proof Versions: ATEX II 3 DG, cCSAus

Optional versions available for use in hazardous areas according to international safety standards.

Special Voltages

Special voltages and configurations available upon request.

JOEST offers customized adaptations of the drives tailored to specific technical requirements and regional conditions.