Linear Motion Screens

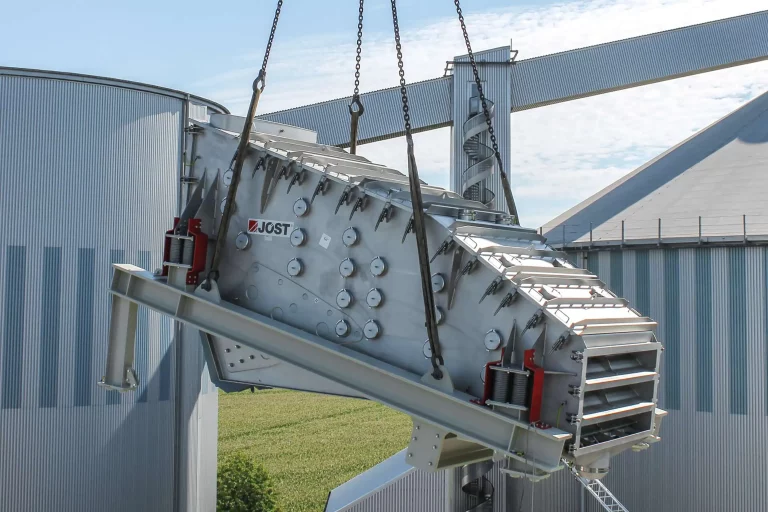

JOEST Linear motion screens are high-performance machines for pre-classification, control screening, or final classification of bulk materials ranging from fine to coarse particles. Thanks to their linear motion, they can be precisely adapted to the screening behavior of different materials – whether for uniform particle size distribution, high throughput, or demanding process conditions.

The machines are available with various drive concepts – from magnetic drives and unbalanced motors to exciter drives – and come in different structural designs. JOEST linear motion screens are available in many versions – as single-deck or multi-deck units, in horizontal or inclined configurations, as well as multi-slope or banana screens. All designs are easily accessible and allow for efficient cleaning; optionally available with ATEX-compliant features.

Thanks to their modular design, they can be used in almost all industrial sectors – from mining & minerals, stone and earth industries, and metal & glass recycling to food and chemical production.

Function

JOEST Linear motion screens operate with a directed linear vibrating motion, in which the entire screen box is set into horizontal or inclined motion. This movement enables continuous, uniform material transport while efficiently classifying the bulk material.

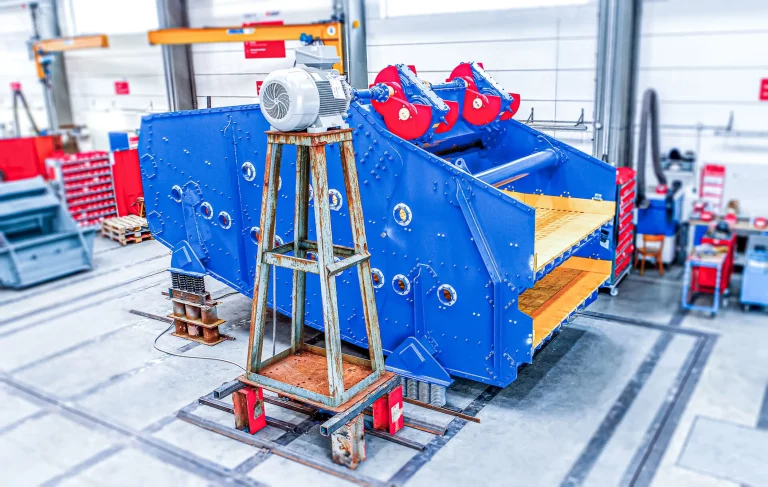

The excitation of the vibration is provided – depending on the design – by unbalanced motors, exciters, or magnetic drives. The choice of drive system depends on the application, screen size, throughput, and desired vibration parameters.

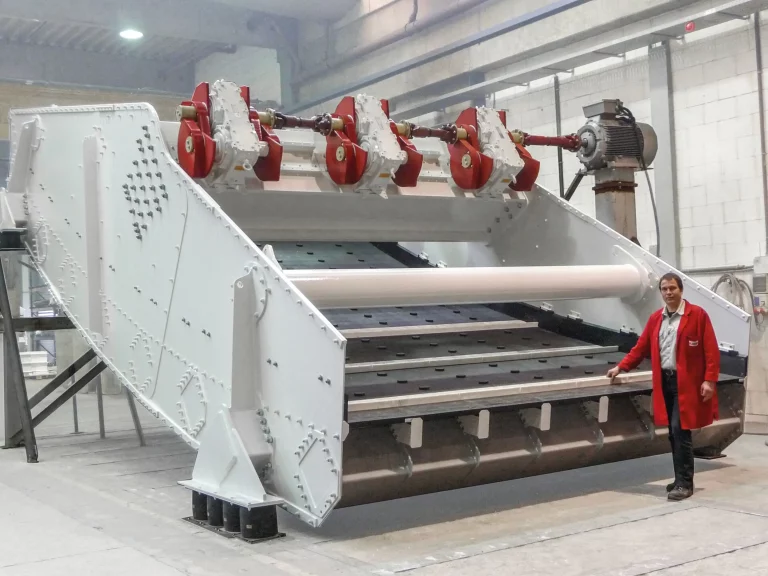

Especially for large screening surfaces or high material loads, synchronized exciter cells are used, allowing high acceleration values.

Depending on requirements, between one and four screen decks can be combined to achieve multiple cut points in a single operation.

The linear vibration ensures high separation accuracy. Thanks to the ability to individually adjust stroke, frequency, and inclination angle, the screen can be precisely adapted to the conveying characteristics of the respective bulk material.

Product Details

The JOEST Linear motion screens stand out because they can be optimally designed for specific applications – ideal for demanding processes, for example in the food, chemical, and bulk material industries.

Hygienic and Flexible Design

For applications with high hygiene requirements, we also offer our machines in stainless steel versions with pickled and passivated surfaces. Depending on the requirements, dust-tight or gas-tight designs are available. Single-deck and multi-deck configurations with up to five screen decks are possible.

Efficient Screen Tensioning and Flexible Screen Surfaces

An optional pneumatic screen-tensioning device allows for quick screen changes, minimizing downtime. Available screening surfaces include wire mesh, perforated plates, or PU system panels – matched to your specific material requirements and process conditions.

Control and Quality During Operation

For maximum process reliability, our Linear motion screens enable sampling and visual inspections during operation – without interrupting production.

Options

- Design available as single- to four-deck units for multiple cut points

- Various drive types: unbalanced motors, exciters, magnetic drives, or double-shaft drives

- Horizontal, inclined, as well as banana and multi-slope screen decks possible

- Screening surfaces made of PU, wire mesh, perforated plates, or bar grates

- Dust-tight enclosures with optional extraction

- Wear protection and reinforced design for abrasive products

- Inspection openings and quick-change systems for maintenance

- ATEX-compliant versions for potentially explosive areas

- Various materials and surface treatments available

- Integrable control, visualization, and process monitoring

Fields of Application

JOEST Linear motion screens are suitable for a wide range of screening tasks – from pre-screening and dewatering to final classification. Thanks to their modular design, variable screen decks, and adaptable drive systems, they can be precisely tailored to material behavior, particle size, and process requirements. They are particularly well-suited for dry, free-flowing, or slightly moist bulk materials with medium to fine particle sizes.

Sand, chippings, gravel, crushed natural stone, hard rock

Construction debris, waste glass, plastic flakes, metal scrap

Granulates, powders, fertilizers, additives

Flour, starch, sugar, flakes, confectionery

Equipment Options

For maximum flexibility in function, installation, and maintenance, JOEST offers numerous equipment options – individually configurable for product, process, and environment.

Single- to four-deck designs possible

Multiple screen decks enable simultaneous classification of several fractions – efficient, space-saving, and flexible in particle distribution.

Selectable drive systems to suit requirements

Unbalanced motors, exciters, or magnetic drives – matched to product, machine size, and desired vibration characteristics.

Horizontal, inclined, or banana screen decks

The deck design can be selected according to the screening task – for particularly gentle material handling and longer screening sections.

Individually combinable screen surfaces

PU, rubber, wire mesh, perforated plates, or bar grates – all screening surfaces can be flexibly adapted to product behavior and cut size.

Dust-tight design with suction hood

For dusty bulk materials or sensitive production areas – available with integrated extraction to improve workplace safety.

Reinforced design for abrasive materials

Robust construction with wear plates and reinforced components – ideal for high feed rates or abrasive media.

Inspection openings and exchangeable screen frames

For easy cleaning and maintenance – quick access to the screen decks without disassembly, optionally with quick-change system.

ATEX-compliant version available

Safe operation even in potentially explosive areas – with certified components according to ATEX Directive, available on request.

Selectable materials and surface finishes

Mild steel or stainless steel, blasted, painted, coated, or polished – individually adaptable to process and product requirements.

Integrated control and process monitoring

Available with complete plant control technology, touch panel, visualization, and vibration monitoring for process-safe operation.

Advantages

JOEST Linear motion screens stand out for their high separation accuracy, versatile configurability, and robust design – ideal for demanding screening processes in continuous operation.

High separation accuracy with uniform material flow

The linear vibration motion enables precise classification and consistent conveying – even with sensitive or critical materials.

High flexibility in screen deck design

Horizontal, inclined, or banana design – the construction can be precisely adapted to product characteristics and the desired screening effect.

Custom design on request

Adaptation to material behavior, bunker pressure, particle size, moisture content, and other process parameters available on request.

Versatile drive concepts available

Unbalanced motors, exciters, or magnetic drives provide process-specific vibration and optimal energy efficiency.

Individually adaptable screening surfaces

PU, wire mesh, rubber, perforated plates, or bar grates – the choice of screening medium is tailored to material, wear characteristics, and target particle size.

Robust design for demanding processes

Sturdy frames, reinforced components, and wear protection ensure reliable operation even with abrasive and coarse bulk materials.

Maintenance-friendly design with inspection access

Quick-change systems and large openings make cleaning, inspection, and maintenance easier – minimizing downtime.

ATEX-compliant and hygienic design available

Available on request in explosion-protected or food-grade versions – including documentation and certified components.

Your material. Our technical center.

At the JOEST technical center, we test your materials under real-world conditions – and develop a practical concept that works.