Non-Discharging Shakeout

The JOEST shakeout is specifically designed for the robust separation of molding sand and castings in foundry operations. It is used wherever molding boxes need to be emptied efficiently and sand lumps reliably broken down – particularly in large casting processes with high-mass cold box molding materials.

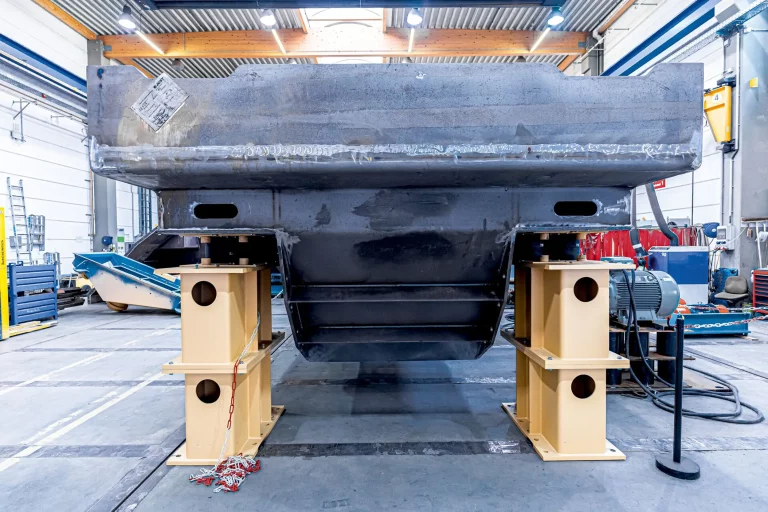

Targeted vertical oscillations break up the mold block while castings remain on the grate. The system is engineered for extreme loads of up to 80 tons and can be customized as a single- or multi-part design to accommodate various spatial requirements. Isolation frames can be integrated to effectively isolate vibrations from the foundation, ensuring smooth and reliable operation even under heavy loads.

With its wear-resistant construction, high mechanical strength, and modular design, JOEST’s shakeout technology is a proven solution for demanding foundry processes – efficient, low-maintenance, and built to last.

FUNcTION

During the shakeout process, the mold box – typically positioned on the grate by crane or transport vehicle – is subjected to vertical vibrations generated by the shakeout grate. These vibrations act directly on the mold block. The binder-hardened molding sand is broken down into smaller lumps and falls through the defined openings of the grate system. The castings remain on top of the grate and can be removed manually or via automation. The system ensures controlled sand discharge while minimizing mechanical stress on adjacent equipment components through an optionally integrated counter-vibration unit.

Product details

The JOEST shakeout is designed for large mold weights and high throughput rates. Its single- or multi-part construction allows for sizes up to 4,500 × 4,500 mm and loads of up to 80 tons. The grates are made of wear-resistant material and are specifically engineered to withstand the impact of hot sand masses and heavy castings. The vibration unit is isolated from the foundation to prevent unwanted force transmission and to increase the overall service life of the system.

Options

- Single- or multi-part design up to 4,500 × 4,500 mm

- Grate elements made of wear-resistant special steel

- Counter-vibration frame for foundation isolation

- Adaptable to individual sand handling and conveying concepts

- Compatible with sand hoppers and conveying systems

- Drive configuration depending on machine size

Fields of Application

The JOEST shakeout is specifically designed for foundries and is used in the cold box process to reliably separate molding sand from the casting.

Shakeout of large cold box molds, casting-sand separation

Break-up of compacted sand blocks, processing of hot and abrasive molding materials

Use in central shakeout stations, integration with sand extraction and conveying systems, crane systems, and dust collection units

Equipment Options

As a central element in the shakeout process, the JOEST shakeout is used in a wide variety of foundry environments. It ensures safe and efficient separation of mold blocks and castings and can be seamlessly integrated into both manual and automated system concepts.

Modular grate design

Single- or multi-part systems for optimal adaptation to available space and process layout.

Counter-vibration frame

Ensures low-vibration operation and protects surrounding components and foundations.

Highly wear-resistant grate elements

Designed to withstand extreme loads from heat, abrasion, and impact forces.

Sand collection and conveying units

Can be combined with hoppers and discharge systems for seamless integration into material logistics.

Replaceable grate segments

Facilitates maintenance and repair – fast spare parts availability thanks to standardized components.

Sand collection hoppers

Optimal guidance and collection of loosened sand – adaptable to downstream conveying systems.

Integration with discharge systems

Dust protection enclosure

Optional housing to minimize dust and noise emissions at the workstation.

Interfaces for process control

Prepared for sensor integration, vibration monitoring, or connection to existing control systems.

Advantages

The JOEST shakeout is designed for maximum durability and long service life. It combines a robust design with functional efficiency and makes a key contribution to process reliability in foundry operations. Thoughtful technical details and application-oriented equipment options ensure that the system operates not only reliably but also economically – even under the toughest operating conditions.

DESIGNED FOR LARGE MOLD WEIGHTS

High load capacity up to 80 t for large mold boxes and heavy castings.

EFFICIENT SAND SEPARATION

Targeted vibration input reliably breaks up even compacted or bonded sand structures.

FOUNDATION-FRIENDLY DESIGN

Vibration-isolated installation reduces vibration transmission and protects surrounding structures; optional isolation frame for optimal support.

DURABLE COMPONENTS

Wear-resistant grate elements for continuous operation under thermal and mechanical stress.

MODULAR DESIGN

Flexible sizes and customer-specific adaptation to factory layout and material flow.