Spiral Elevators

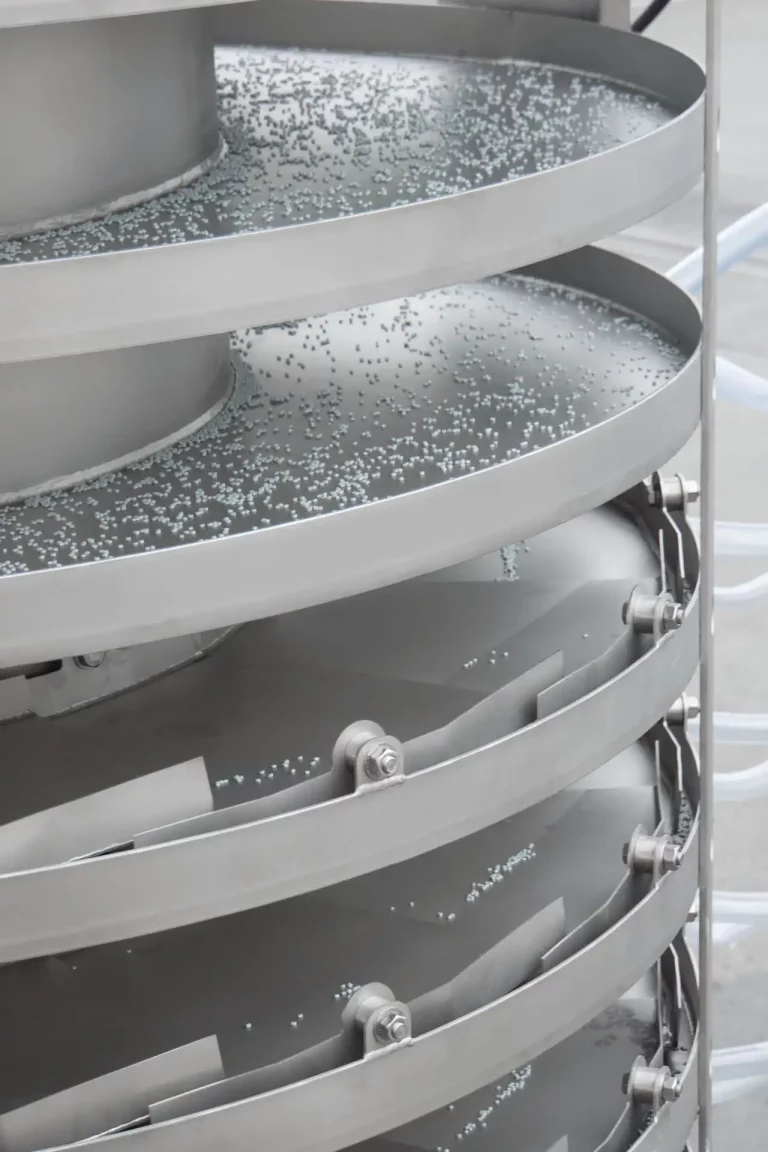

JOEST Spiral Elevators are the ideal solution for vertical conveying of bulk materials in confined spaces. The helical conveyor trough spirals around a central torsion tube, allowing for gentle and energy-efficient transport without the need for additional transfer points or conveying elements.

Thermal processes can also be integrated directly into the system: Heated or cooled trough bottoms enable simultaneous conveying and temperature control in a single unit – saving space and reducing technical complexity.

Various design options, such as dust- and gas-tight configurations, air- or fluid-cooled systems, and coated troughs, offer a wide range of process engineering applications.

Each unit is custom-designed to meet specific conveying heights, diameters, heat transfer surfaces, and industry requirements.

Whether in the foundry, food, chemical, or plastics industries – JOEST Spiral Elevators stand for robust design, high flexibility, and reliable performance in the most compact footprint.

FUNcTION

For thermal processing, double-walled, fluid-conducting troughs are available, allowing targeted heat input or removal. Heat transfer takes place via conduction – the product does not come into contact with the medium (e.g. water, steam, or thermal oil).These machines are available in various diameter ranges and with conveying heights up to 7,000 mm. Inverted designs typically reach heights of up to 5,000 mm. Depending on the configuration, heat transfer surfaces of up to 35 m² can be realized.

A wide range of equipment options – including ATEX-compliant versions, hygienic access points, resonant casings, and flanged inlets and outlets – make JOEST spiral elevators a versatile system solution for a broad spectrum of industries and requirements.

Product details

- Heat transfer surfaces up to 35 m²

- Infeed temperature for cooled applications up to 500 °C

- Infeed temperature for tempered or cooled applications up to 150 °C

- Inner diameters from 400 to 1,000 mm

- Outer diameters from 620 to 1,900 mm

- Inverted design: from 800 mm (inner) to 1,600 mm (outer)

- Conveying heights up to 7,000 mm; up to 5,000 mm for inverted design

- Also available as a spiral casting cooler

Options

- Double-walled, fluid-conducting troughs (for heating/cooling)

- Stationary or resonant casings (e.g. made of sheet metal or silicone cloth)

- Flanged inlets and outlets

- Cleaning nozzles and integrated drain options

- Residue-free discharge

- ATEX-compliant design

- Gas-tight execution

- High surface quality (ground, electropolished)

- Modular design (segment combinations for conveying height)

- Individually adjustable throw angle and amplitude

- Hygienic design for food and chemical industries

- Special design available for cooling castings

- Testing with original material possible at the JOEST Test Center

Fields of Application

JOEST spiral elevators are used wherever bulk materials need to be conveyed vertically and optionally subjected to thermal treatment. Typical applications include the plastics industry (e.g. granulate cooling), the chemical industry (e.g. drying or tempering of sensitive products), and food processing, where hygienic conveying and precise temperature control are essential. The combination of conveying and thermal technology also ensures high process efficiency with a minimal footprint for applications involving catalysts, glass fibers, or castings.

Fertilizers, Titanium dioxide, Zinc sulfate, Copper sulfate

Fine chemicals, raw material mixtures, powders and crystalline substances, moist or reactive bulk materials

Food granulates, powdered ingredients, additives and blended products, heat- or cooling-sensitive components

Active materials, supported catalysts, sensitive bulk materials with reactive properties

Glass fibers, fiber bundles and fragments, sharp-edged or lightweight bulk materials

Cooling of castings in wet casting processes, such as brake discs

Equipment Options

With numerous configuration options, our spiral elevators can be perfectly tailored to your application. Whether thermal processing, hygienic cleaning, or custom integration – here is an overview of the key features available:

Double-walled, fluid-conducting troughs

Enable targeted temperature control via heat conduction – using water, steam, thermal oil, or process fluids.

Stationary or resonant casings

Custom-made in sheet metal or silicone – either fixed in place or flexibly resonating with the system.

Flanged inlets and outlets

Standardized or custom-adapted interfaces for safe integration into existing process systems.

Hygiene-friendly cleaning solutions

Residue-free discharge, cleaning nozzles, and integrated drain options allow for easy and safe cleaning.

ATEX-compliant designs available

For safe operation in hazardous areas – gas- and dust-tight as required.

High surface qualities achievable

Mechanically ground or electropolished – suitable for hygiene-critical applications or sensitive products.

Gas-tight system variants available

For applications with protective atmospheres or process gases – ideal in combination with thermal treatment.

Modular design for maximum flexibility

Individually combinable modules for trough, drive, and outlet – ideal for installations with limited space or maintenance access.

Individually adjustable throw angle

Conveying characteristics and speed can be precisely adjusted via frequency, amplitude, and directional control.

Testing possible at the JOEST test center

Customer-specific tests with original material to verify temperature behavior and conveying performance.

Advantages

JOEST spiral elevators offer a well-engineered combination of vertical conveying and integrated temperature control. Their compact design, versatile configuration options, and proven vibration conveying technology ensure maximum efficiency with a minimal footprint – tailored to your specific application.

Compact and space-saving design

Vertical conveying in the smallest footprint – ideal for limited installation heights and for reducing transfer points in the process.

Conveying and thermal processing in one system

Material transport and thermal treatment in a single unit – reduces equipment complexity and significantly increases process efficiency.

Gentle conveying through micro-throw principle

The vibratory motion enables uniform, product-friendly transport – even sensitive materials remain undamaged.

Precise adjustment to product and process

Conveying capacity, amplitude, and throw angle can be individually adapted to the material and the required flow rate.

Thermal processing without product contact

Heat transfer takes place via conduction without direct contact – the product remains free from media such as water, oil, or steam.

Large heat transfer surface possible

Depending on the design, up to 35 m² of transfer surface can be achieved – ideal for efficient heating and cooling processes in material flow.

Hygiene-friendly designs available

Residue-free discharge, smooth surfaces, cleaning nozzles, and drain options enable hygienic operation during product changeovers.

ATEX- and gas-tight versions available

Also suitable for use in hazardous areas or where a protective atmosphere is required – safe and compliant with relevant standards.