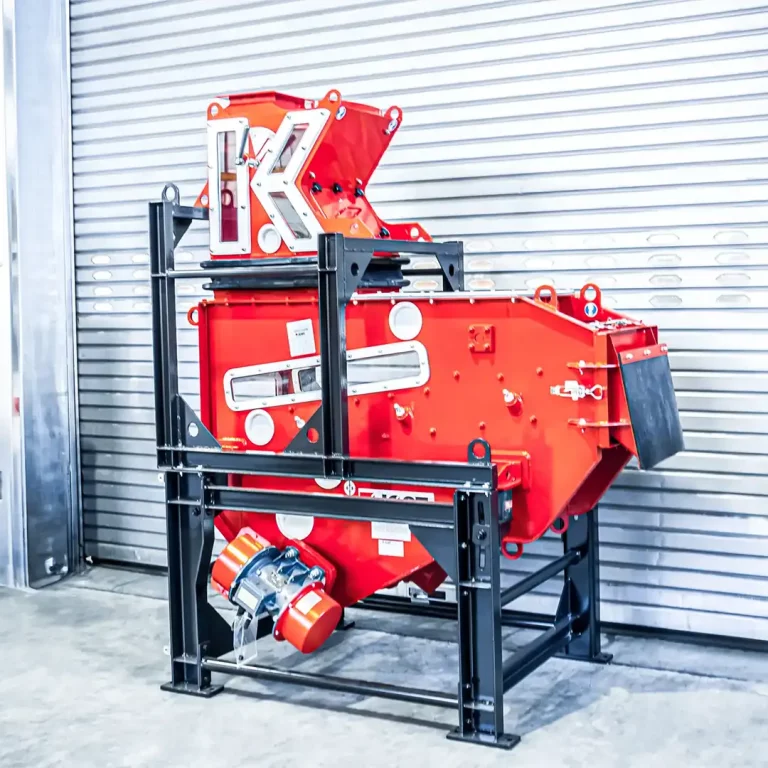

Separation Table

The JOEST Separation Table is the ideal solution for separating dry, free-flowing bulk materials with particle sizes of up to approx. 20 mm. The system uses a fluidized bed in which the material behaves like a liquid under the combined action of air flow and vibration: heavy particles sink to the bottom, while light particles “float” on top – ensuring clean, reliable separation even for heterogeneous material streams.

The Separation Table is suitable for a wide range of recycling applications, such as cable granulate, tire granulate, ASR or shredder fines, construction debris, or glass. It is particularly effective when combined with a preceding JOEST Air Separator, which removes ultra-light fractions (e.g. films, dust, or fluff) in advance – resulting in more stable fluidization conditions, higher throughput, and consistently precise separation quality.

FUNcTION

In the JOEST Separation Table, the material to be sorted is centrally fed into the machine’s vibratory hood. Inside, an integrated distribution device ensures an even spread of material across the entire machine width.

Vibration of the separating deck, combined with an upward air flow through the perforated fluidizing plate, creates a so-called fluidized bed. In this bed, the material behaves like a liquid, stratifying according to density: heavy particles settle downward, while lighter particles rise to the surface.

Thanks to the deck’s inclination and the directed vibration pattern, the material is separated into two fractions: heavy material moves upward toward the higher discharge end, while light material flows downward with the slope and is discharged over a weir. A adjustable backflow flap retains any misplaced light material, further enhancing separation efficiency.

The required process air is generated by a powerful pressure blower and supplied beneath the fluidizing plate. Dusty exhaust air from the separation process is reliably conveyed to a filter system for cleaning.

For materials containing a high proportion of ultra-light components – such as films, insulation materials, or dust – an optional JOEST Air Separator with upstream feeding chute can be integrated. An adjustable separation flap allows these ultra-light fractions to be removed in advance, preventing them from disrupting the stratification process.

For applications with highly fluctuating feed rates (greater than ±20 %), a dosing feeder with feed hopper is recommended. This ensures consistent feeding of the Separation Table and thereby maintains high and stable separation performance.

Product details

The JOEST Separation Table is a compact, highly efficient system for density separation of fine-grained, dry bulk materials. It is particularly well-suited for fractions below 20 mm, where conventional mechanical separation methods reach their limits. Typical applications are found in the recycling industry, such as cable granulate, rubber-textile mixtures, or shredder fines / ASR fine fractions.

At the heart of the system is a fluidized deck. Air is introduced from below and, in combination with a precisely controlled vibratory motion, creates a stratification layer within the material bed. In this layer, particles separate according to their density, shape, and size.

The airflow is generated by a fan and regulated via a frequency converter. Air distribution can be individually adjusted. Likewise, vibration amplitude, frequency, and deck inclination can be set to match the specific process requirements. Separation Tables are available in various sizes and widths, depending on the desired throughput. All models feature a robust design, easy maintenance, and a long service life.

When combined with a preceding JOEST Air Separator, even highly complex material streams can be efficiently separated into valuable individual fractions.

Technical data

Lx B x H [m] | K-Sifter [m] | Dosing station[m] | ||||

|---|---|---|---|---|---|---|

Options

- Various working widths available

- K-Sifter with vibratory feeder trough

- Dosing feeder trough with feed hopper

- Cyclone separator with suction blower and rotary valve and/or filter unit

- Adjustable air distribution and airflow control

- Adjustable inclination of the separation deck

- Various discharge options for light and heavy fractions

- Process visualization with sensors and monitoring

- ATEX-compliant design available as standard

Fields of Application

Cable granulate for recovery of the copper fraction, shredder fines and ASR (Auto Shredder Residue) < 12 mm for recovery of metal fractions, separation of compact or spheroid heavy and light metals in particle sizes up to approx. 12 mm.

Separation of textile components

Fine glass cullet fractions, fine construction debris fractions for recovery of mineral components

Equipment Options

Working widths selectable

Depending on requirements and material throughput, various machine sizes are available – individually tailored to your plant.

Precisely adjustable air distribution and volume

Air volume can be regulated via frequency converter, and air distribution can be fine-tuned in segments via dampers – for optimal fluidization and consistent separation efficiency for any material.

Adjustable amplitude and frequency

Amplitude and frequency of the vibratory motion can be continuously adjusted via frequency converter – for ideal adaptation to material behavior and separation dynamics.

Adjustable deck inclination

The deck angle can be variably set – ensuring ideal adaptation to product behavior and separation dynamics.

Flexible discharge options for both fractions

Light and heavy fractions can be discharged via various outlet systems – with adaptable transfer points to downstream conveying equipment.

Process visualization and sensor integration

Optional sensors for monitoring air flow, material level, or speed – including display and control systems.

ATEX-compliant design

For use in potentially explosive atmospheres, ATEX-compliant versions with certified components are available.

Advantages

The JOEST Separation Table delivers precise density separation, high separation accuracy, and flexible adaptability – even with fine-grained, challenging materials. Its robust design, easy maintenance, and customizable configuration make it ideal for efficient fine classification in recycling and material recovery processes.

Precise density separation in fine particle sizes

Even the smallest particles below 2 mm are reliably separated by gravity – ideal for material recovery and final cleaning.

Higher separation accuracy through combination with JOEST Air Separator

Particularly effective for products with high proportions of films, foam, and/or insulation material.

Exact process adjustment through flexible parameters

Air volume, vibration characteristics, and deck inclination can be individually adjusted – for optimum results with varying products or material mixes.

Low energy demand with high efficiency

Purely mechanical operation with air support: energy-efficient, quiet, and economical – even in continuous operation.

Robust, low-maintenance design for long-term operation

The single-chamber system with externally positioned pressure blower prevents material build-up – ensuring low-maintenance continuous operation.

Optional ATEX version available

ATEX-compliant designs are generally available for use in explosive atmospheres.