Shakeout

The JOEST Shakeout is a high-performance solution for the automated separation of sand lumps and castings in foundry production. Especially in wet casting processes, it ensures reliable and gentle material processing – even under high temperatures and mechanical loads.

Its modular design, robust construction, and precisely adjustable vibration parameters allow optimal adaptation to a wide variety of requirements.

The use of high-quality materials such as manganese steel, individually configurable grate systems, and a low-vibration design ensures maximum operational safety while keeping noise levels low. Combined with automated control systems, energy-efficient drives, and ergonomic maintenance concepts, the shakeout becomes a key component of modern foundry operations.

FUNCTION

After excavation, the still in-tact molds are transferred either directly or via a vibrating feeder to the shakeout. There, targeted vibration breaks up the mold, enabling separation of castings and molding sand.

The sand falls through specially designed grate openings, while the casting is conveyed longitudinally. The micro-throw action of the trough ensures gentle and uniform separation without applying mechanical stress to the casting. The sand is then directed to return or sand reclamation, while the castings move on for further processing.

PRODUCT DETAILS

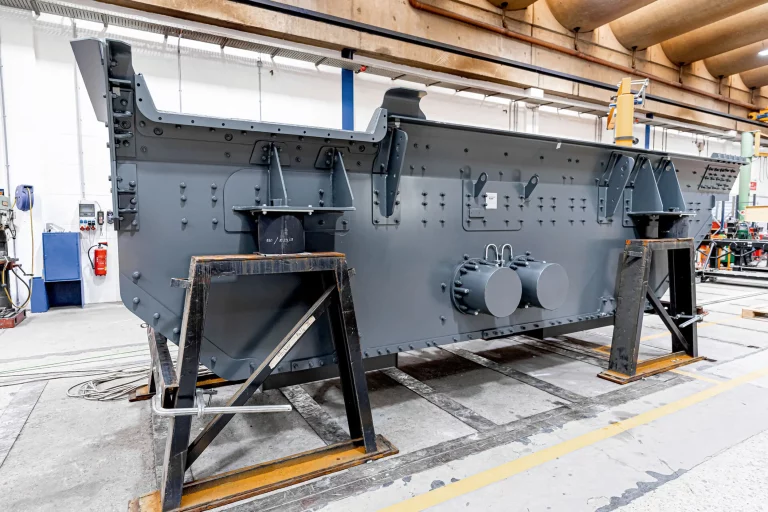

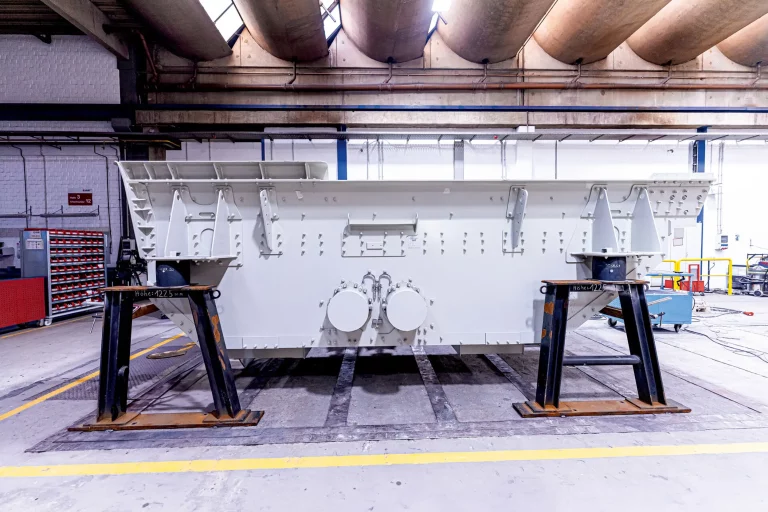

The JOEST Shakeout is specially designed to withstand the harsh conditions in foundries. The trough body is made of torsion-resistant steel profiles that ensure high stability while providing a vibration-optimized design. All wear-exposed components such as grates, side plates, and crossbeams are designed for maximum service life – e.g. by using wear-resistant manganese steel plates and riveted joints.

The system has a modular design and can be individually adapted in width, length, and grate geometry. Depending on the requirements, different grate types with defined hole shapes are used to ensure clean separation with minimal sand loss. Vibration is generated by frequency-controlled unbalance motors, which – in combination with electronically adjustable vibration angles – allow precise adaptation to the shape and weight of the sand lumps.

Thanks to the integrated process control system, various operating modes can be mapped – from continuous to timed or interval-controlled operation. All components are easily accessible for maintenance and are designed for long-term use under high thermal loads.

OPTIONS

- Pre- or main shakeout

- Grates with variable hole geometry

- Various widths and lengths

- Drive units depending on machine size

- Integration of casting ladle chutes

- Noise-dampening installation

- Dust protection covers

Fields of Application

The JOEST shakekout is used in foundries worldwide for separating moulding sand lumps and castings. It is particularly suited for green sand casting, hot casting operations, and automated production lines. With its flexibility for different casting geometries, low-noise and low-vibration operation, and easy integration into existing systems, it is ideal for both new installations and modernisation projects.

Separation of molding sand and castings in wet casting processes, used in iron and steel foundries for processing hot mold lumps directly after shakeout.

Integration into fully automated high-speed lines, feeding and discharge of pre- and main shakeout systems, connection to casting ladle chutes, cooling systems or sand return units.

Retrofitting of existing foundry lines, space-saving installation in confined layouts, adaptation to variable lump sizes and weights.

Equipment Options

To optimally meet individual requirements, JOEST offers a wide range of proven equipment options. These allow the shakeout to be precisely adapted to existing processes, space constraints and material properties – for maximum efficiency and operational safety in everyday foundry operations.

Electronically Adjustable Vibration Parameters

Conveying capacity and dwell time can be adjusted steplessly – ideal for changing product types.

Manganese Steel Grates

Long service life due to robust design – engineered for continuous operation in foundries.

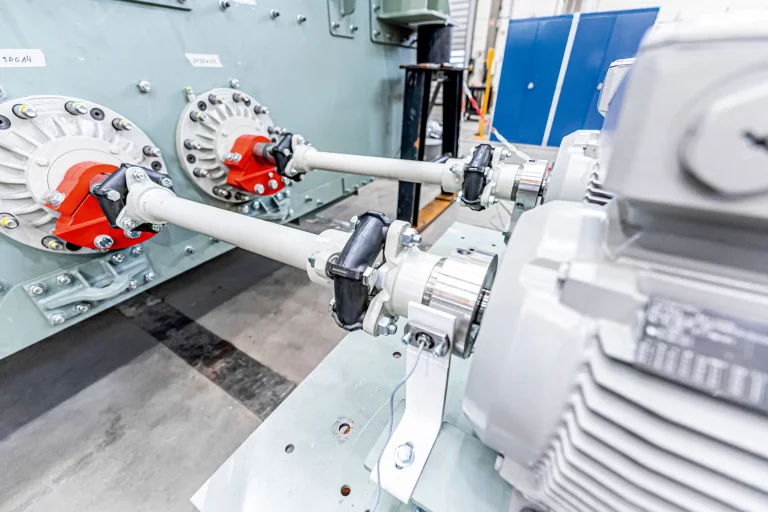

Frequency-Controlled Unbalanced Motors

Efficient operation with precise vibration control – for optimum process control.

Separate Pre- and Main Shakeouts

Combinable systems for integration into complex production lines.

Flexible Width and Length Configurations

Precisely tailored for any installation situation – from compact lines to large foundries.

Dust Protection Cover

Reduces workplace emissions – fully enclosed upon request.

Advantages

The JOEST shakeout combines technical robustness with intelligent design. It offers not only reliable separation of molding sand and castings, but also high process stability, long service life and low operating costs. The combination of a well-engineered design and application-oriented equipment provides measurable advantages in daily operation – even under the toughest foundry conditions.

GENTLE SEPARATION

Smooth vibration protects sensitive castings from damage.

LONG SERVICE LIFE

Low-wear design with robust manganese steel components.

PROCESS-RELIABLE & EFFICIENT

Reliable separation even with high throughputs and varying lump sizes.

LOW NOISE EMISSIONS

Sound-insulated design enables ergonomic operation in the plant environment.

ENERGY-EFFICIENT

Optimized drive unit with demand-based vibration adjustment.

ADAPTABLE & MODULAR

Flexible design based on installation layout, cycle rate, and material flow.

Our Shakeout – Simply Explained

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYour Material. Our Test Center.

Before our systems are used in production, they undergo extensive testing in our in-house technical center. There, we analyze the behavior of your materials under realistic operating conditions and develop customized, application-oriented solutions.