JOEST AUSTRALIA

Lithium Process Equipment

Expansion of the activity in the field of battery metals

![]()

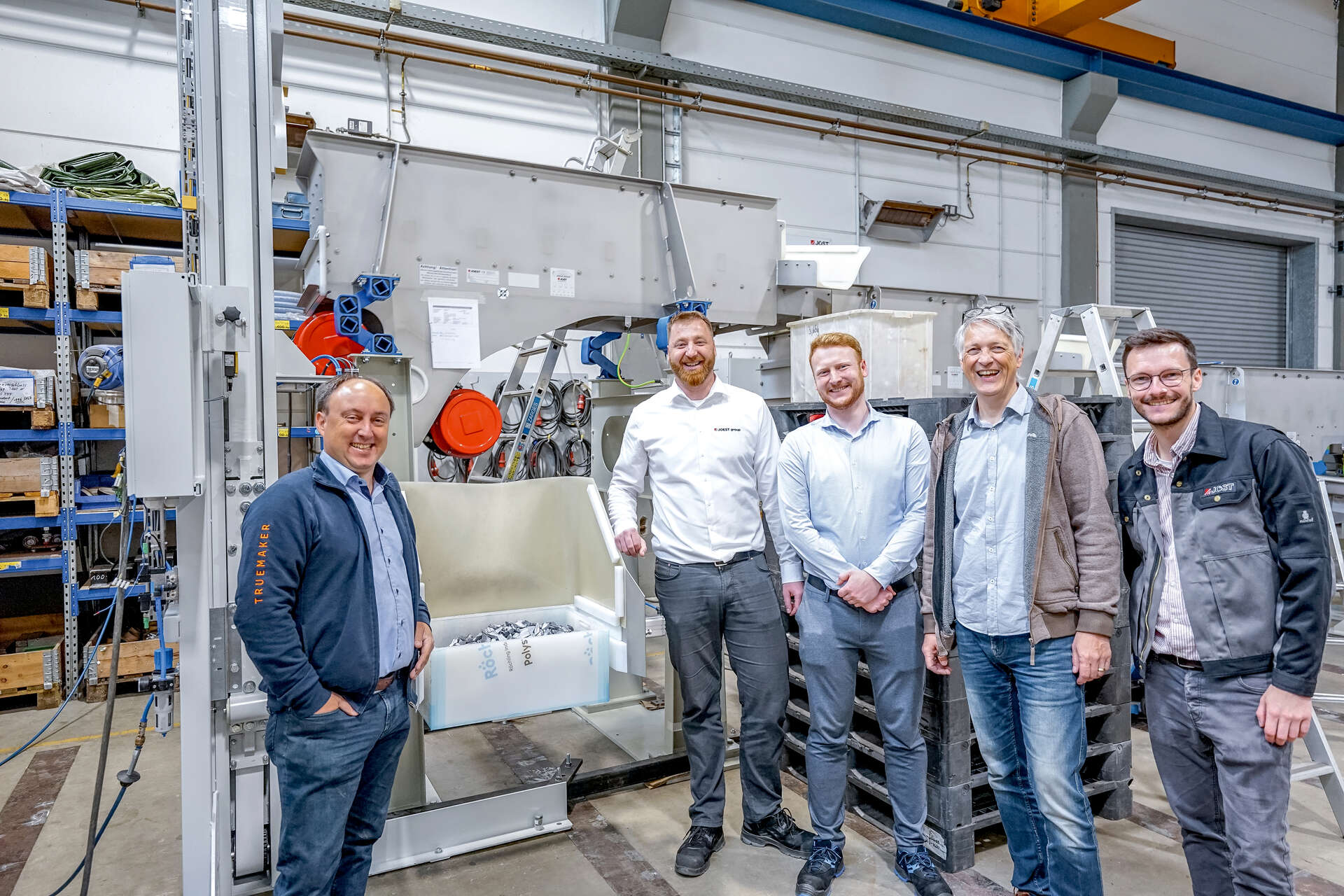

In recent years, JOEST Australia has increased its footprint within the Australian battery metals industry.

JOEST Australia has delivered a package of 20 new machines comprising 18 different sizes and configurations, from dry scalping and sizing through to wet screening applications, to process the spodumene ore used in the conversion process to yield lithium hydroxide for the expanding battery industry.

Due to the project‘s specific requirements, JOEST Australia personnel worked in close collaboration with the customer’s process design team to optimise the feeding and screening equipment used in this latest landmark greenfield project.

Weitere Beiträge

Today, we had the pleasure of welcoming FUNOSA from Spain to our headquarters in Dülmen for the factory acceptance test of their new customized Vibration Vonveying Systems for the foundry industry.

At yesterday’s triathlon in Münster, our #JOESTeam was on the starting line with two strong relay teams and two solo athletes – all pushing through in over 30°C! ☀️💪

Battery Recycling Conference & Expo, Metal Recycling Conference & Expo & E-Waste World Conference & Expo was packed with inspiring conversations, new ideas and strong momentum for the future of battery and metal recycling. ♻️🔋

For a demanding coal preparation plant, JOEST delivered a complete screening and feeding package. From sizing to dewatering – every JOEST machine contributes to a smooth, efficient process.