JOEST AUSTRALIA

Lithium Process Equipment

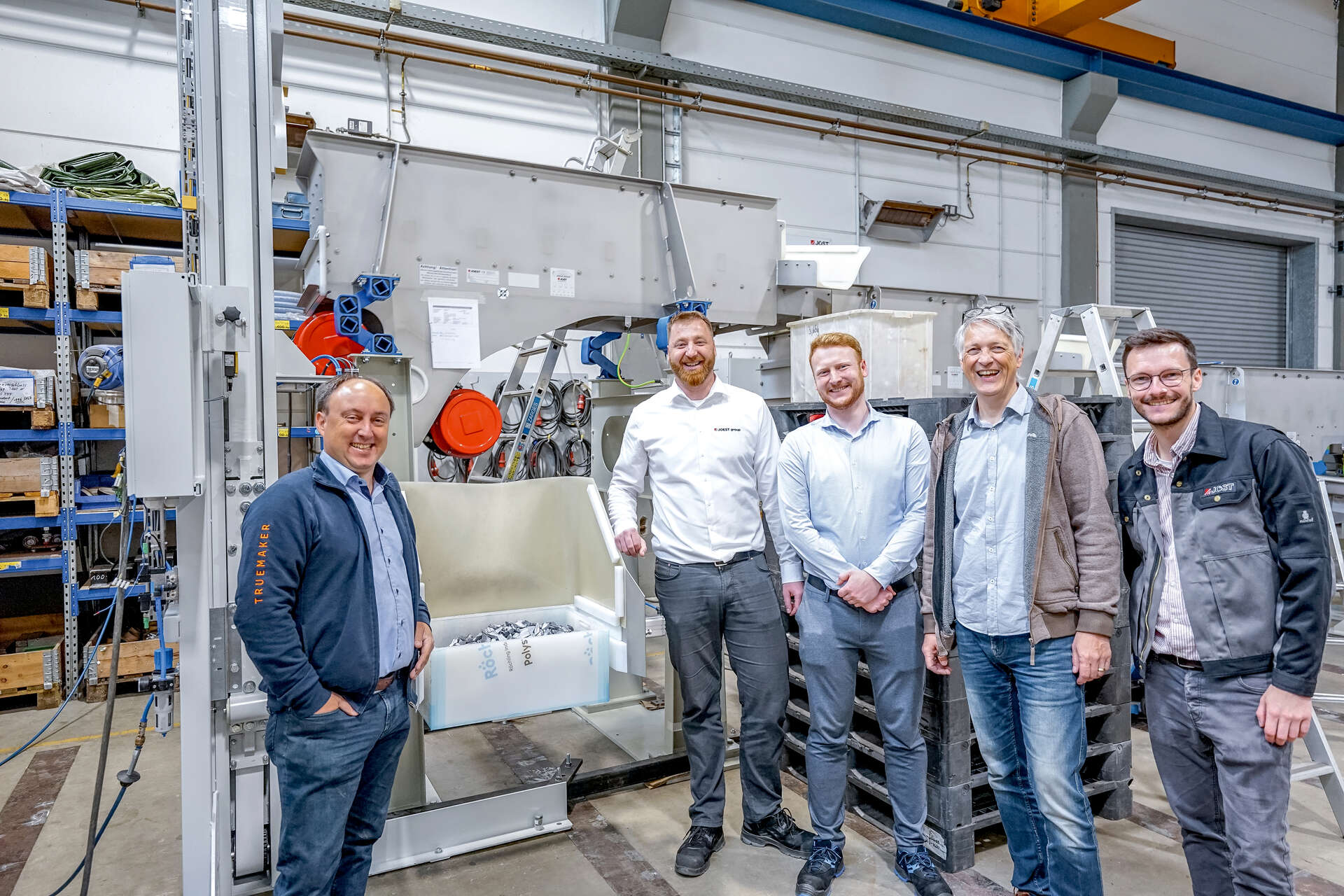

Expansion of the activity in the field of battery metals

![]()

In recent years, JOEST Australia has increased its footprint within the Australian battery metals industry.

JOEST Australia has delivered a package of 20 new machines comprising 18 different sizes and configurations, from dry scalping and sizing through to wet screening applications, to process the spodumene ore used in the conversion process to yield lithium hydroxide for the expanding battery industry.

Due to the project‘s specific requirements, JOEST Australia personnel worked in close collaboration with the customer’s process design team to optimise the feeding and screening equipment used in this latest landmark greenfield project.

Weitere Beiträge

The Berfus Info Exchange 2024 in Nottuln at the Liebfrauenschule was a complete success for us at JOEST and a great opportunity to get in touch with many committed young people. As an internationally active company, we are always happy to introduce young talents to our diverse training and career opportunities.

The Hey Job Apprentice Bus Tour 2024, which took place on October 10, was a complete success. Pupils from secondary schools in Dülmen had the opportunity to visit a total of 14 local companies on five different routes. The tour was organized by the City of Dülmen’s business development department and offered pupils in the 9th and 10th grades an ideal opportunity to introduce themselves directly to companies and gain an insight into various training occupations.

On 25.09.24, our #JOESTeam was at the “Anschub” training fair at Richard-von-Weizsäcker-Berufskolleg in Lüdinghausen!

We look back on a successful exhibition! The JOEST group was proud to be part of the EUROCAST booth – our Polish representation – at the Metal Expo in Kielce, and we would like to thank everyone who visited us at our stand!