MINING, MINERALS & QUARRYING

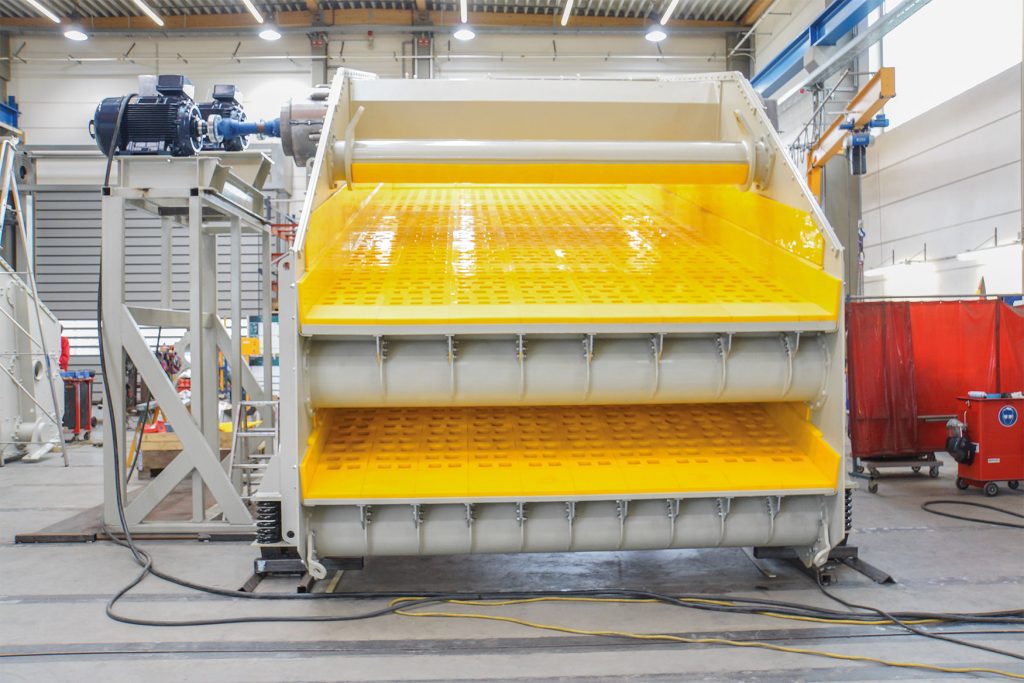

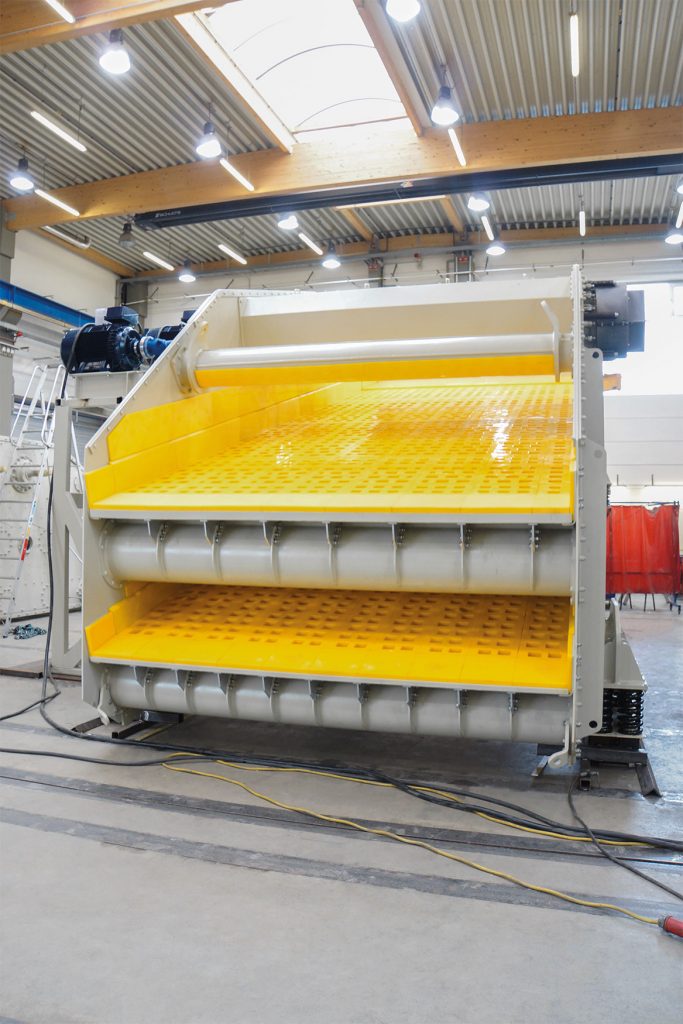

Advantages of the JOEST Double-Shaft Screen

Linear and elliptical motion combined in one screen

JOEST has developed a double-shaft screen for challenging screening applications. The screen allows a changeover from a linear motion to an elliptical motion in order to optimize the screening process fort he actual consistency of the product.

In the actual project in question, around 270 t/h of wet gravel and sand with a grain size of 0–120 mm were screened. This material is highly abrasive, sharp-edged and thus prone to clogging. Due to the twin-deck design, it is possible to produce gravel sizes of 0–4 mm, 4–22 mm and >22 mm.

The special feature of this screen is that it can be operated both as a linear motion as well as an elliptical motion screen. This is made possible by a JOEST electronic control system in combination with the proven, overhead JOEST double-shaft drive.

In addition, the new system with electronic control can variably adjust the angle of attack and the formation of the ellipse. The screen can therefore be precisely adjusted to suit the customer’s screening requirements.

Conveyed material with a tendency to clogging is screened primarily with an elliptical vibrator. To ensure clear screen cuts, it makes sense to switch to a linear vibrator.

The speed and vibration angle can be changed without stopping the machine. This results in different transport speeds and accelerations on each screen deck, which enables optimisations during the ongoing screening process.

When selecting the screening system to be used, JOEST accommodates the customer’s requirements and wishes, thus ensuring that all common screen covering systems can be used. Customers can also choose between oil or grease-lubricated drive units.

Weitere Beiträge

JOEST delivered two high-performance vibrating feeder including tunnel frame, discharge chute and needle gate, each one feeding gabbro up to an edge length of 700 mm as a free stockpile discharge. Our focus was on a robust, blockage-free, wear-optimized and installation-friendly design.

Under the motto #JOESTogether, we organized for the first time an EM pack-watching on our site. It was a fantastic event where we celebrated our community and team spirit.

On the occasion of the farewell of the long-serving managing director, the entire staff of JOEST organized a collective fundraising campaign for the nearby children’s hospice Gut Feismann. A total of over 1,200 euros was collected by the #JOESTeam and ultimately rounded up to 3,500 euros by the management.

Münster

The Job Fair 2024 in Münster was a complete success for us. We are especially proud of our first-time participation as exhibitors.