FOOD INDUSTRY

Drying system for extruded proteins

The contract manufacturer Driessen Food Extrusion, based in Deurne in the Netherlands, processes mixed and powdered plant-based proteins into high-quality intermediates for the Food Industry.

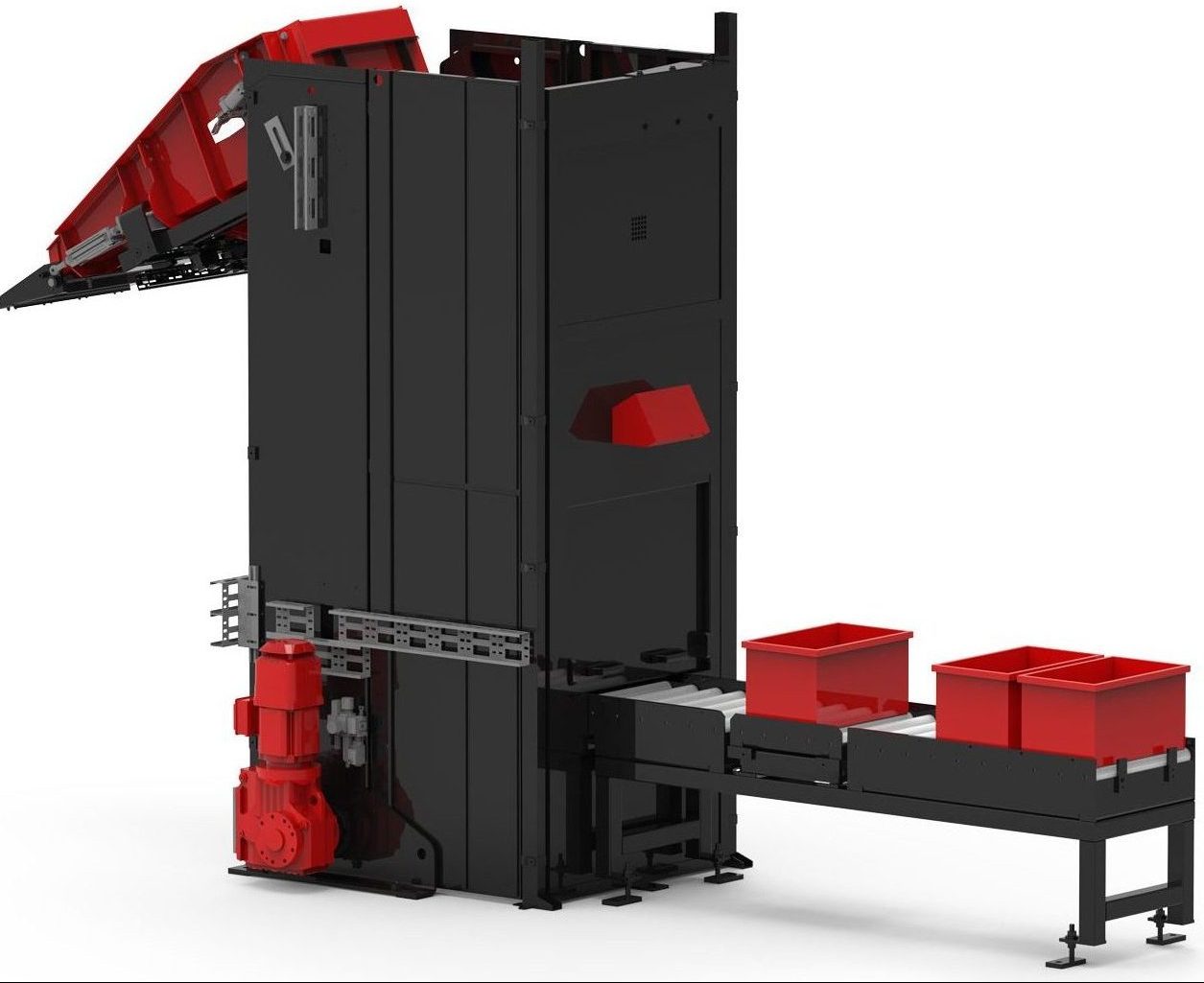

To expand production, JOEST supplied a new drying system. It was designed in close collaboration with the client to meet the special requirements of a contract manufacturer in the Food Industry. The drying system, consisting of a Fluidized Bed Dryer with a process- , heating- , cooling- and exhaust air system as well as a Spiral Conveyor, was already installed this summer. The scope of delivery also included the system controls (control cabinet, control panel, etc.) from JOEST's in-house Control Technology.

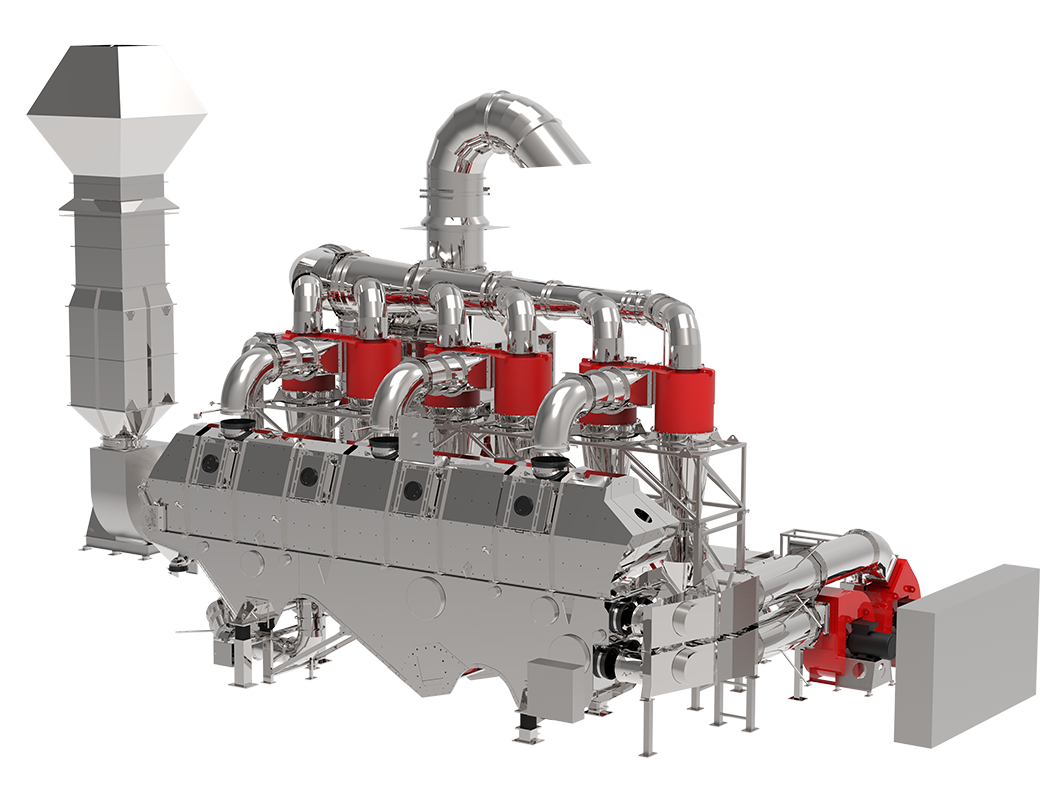

The biggest challenges were the different material shapes and sizes as well as ensuring batch purity for a wide variety of products from changing producers. Depending on the type of product, the drying time varies considerably. Granules, flakes, crumbs and other textures are dried at a throughput of one to two tons per hour to a moisture content of approx. 5%. Furthermore, cross-contamination of the products regarding allergens must be avoided. For this purpose, the surfaces in contact with the product were designed to be gap-free, a cleaning concept was developed, and exhaust air recirculation was eliminated from the design. Instead, a two-stage heat recovery system using heat exchangers was implemented. In this process, the recovered heat is transferred to a water cycle. This allows the regulation of the transmitted heat flow and avoids the formation of condensation.

The Vibrating Fluidized Bed Dryer with a length of more than eight meters includes two drying zones and a cooling zone. The dryer is equipped with an electronic oscillation angle control, which allows the processing time of the product in the dryer to be adjusted during operation. In this way, the system can be optimally adapted to the respective product and the corresponding parameters can be stored for individual products.

Like many projects, this one is guided by JOEST from the first tests at the JOEST Test Center all the way to commissioning and start of production.