SECUNDARY RAW MATERIALS

Handling of mixed packaging waste with the largest vibrating separator worldwide

Biggest Vibration Air Separator “AirVibe” goes to England

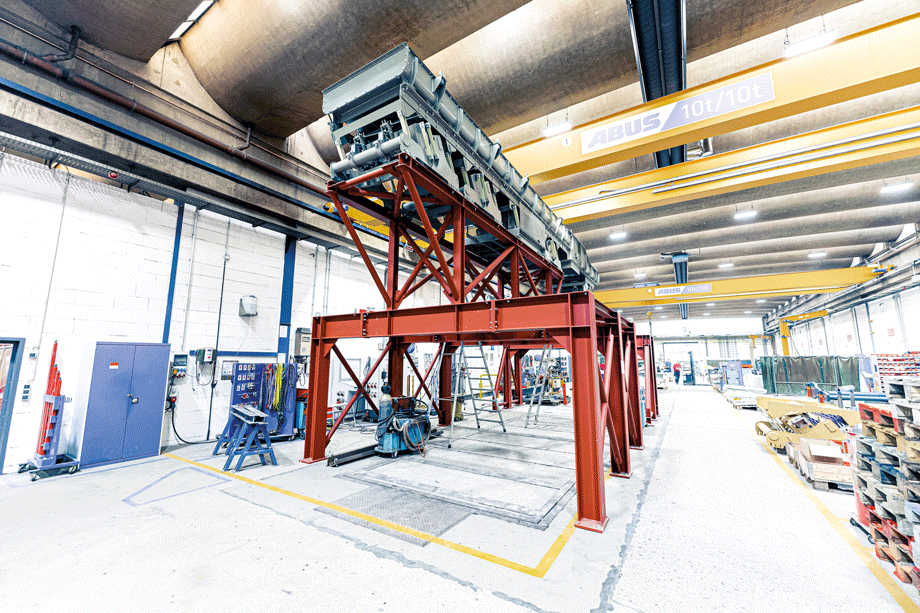

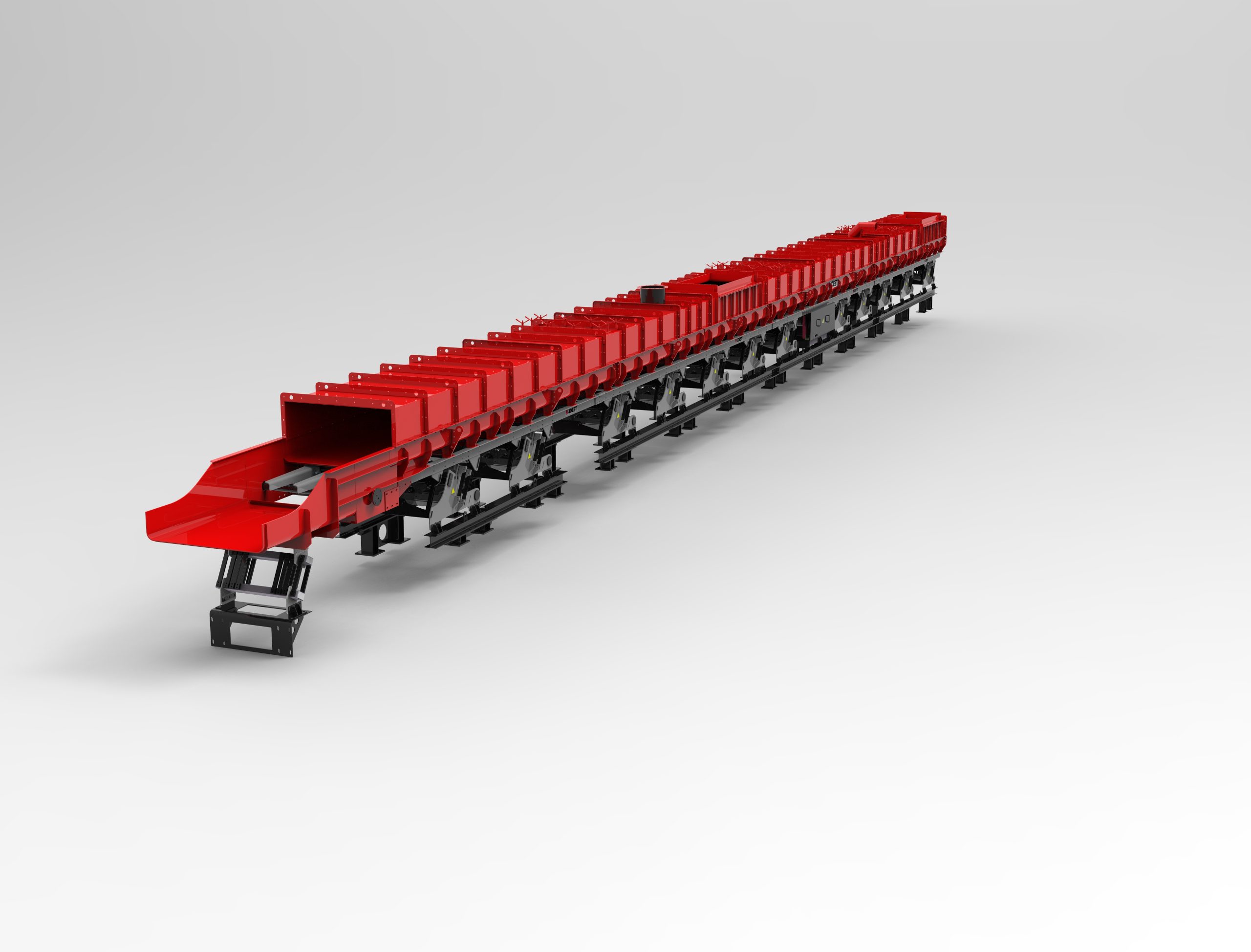

In spring 2018 JOEST delivered the largest AirVibe ever built to England. With a width of 2400 mm and a length of 3700 mm, it has a capacity of 20 t/h. The AirVibe is equipped with a support frame and recirculation mode so that it can be operated in octave.

This separator processes packaging waste consisting of bottle glass, foils, plastic, caps and paper. The AirVibe is used for pre-cleaning the bottle glass and removes the light impurities.

The AirVibe is vibrating with a linear stroke using 2 unbalanced motors. This motion is important for the transport, fluidization and even distribution of the infeed material. An adjustable air knife, positioned at the end of the impact area blows through the material stream. Light material particles like paper, plastic and card board are blown into the expansion room of the AirVibe and discharged at the light material fraction of the end of the separator. The medium weight particles which were not separated in the first separation stage based on size and shape hit an adjustable separation plate. Especially light particles with a larger surface area and those with a higher grip will be moved over the separation plate due to the linear stoke of the machine and added to the light material fraction.

The vibrating separator AirVibe has a fixed place in the JOEST product range for many years and is a worldwide success story.

Weitere Beiträge

JOEST delivered two high-performance vibrating feeder including tunnel frame, discharge chute and needle gate, each one feeding gabbro up to an edge length of 700 mm as a free stockpile discharge. Our focus was on a robust, blockage-free, wear-optimized and installation-friendly design.

Under the motto #JOESTogether, we organized for the first time an EM pack-watching on our site. It was a fantastic event where we celebrated our community and team spirit.

On the occasion of the farewell of the long-serving managing director, the entire staff of JOEST organized a collective fundraising campaign for the nearby children’s hospice Gut Feismann. A total of over 1,200 euros was collected by the #JOESTeam and ultimately rounded up to 3,500 euros by the management.

Münster

The Job Fair 2024 in Münster was a complete success for us. We are especially proud of our first-time participation as exhibitors.