PRIMARY RAW MATERIALS

JOEST delivers one of the

worldwide largest Vibrating Screens

for the aggregate industry

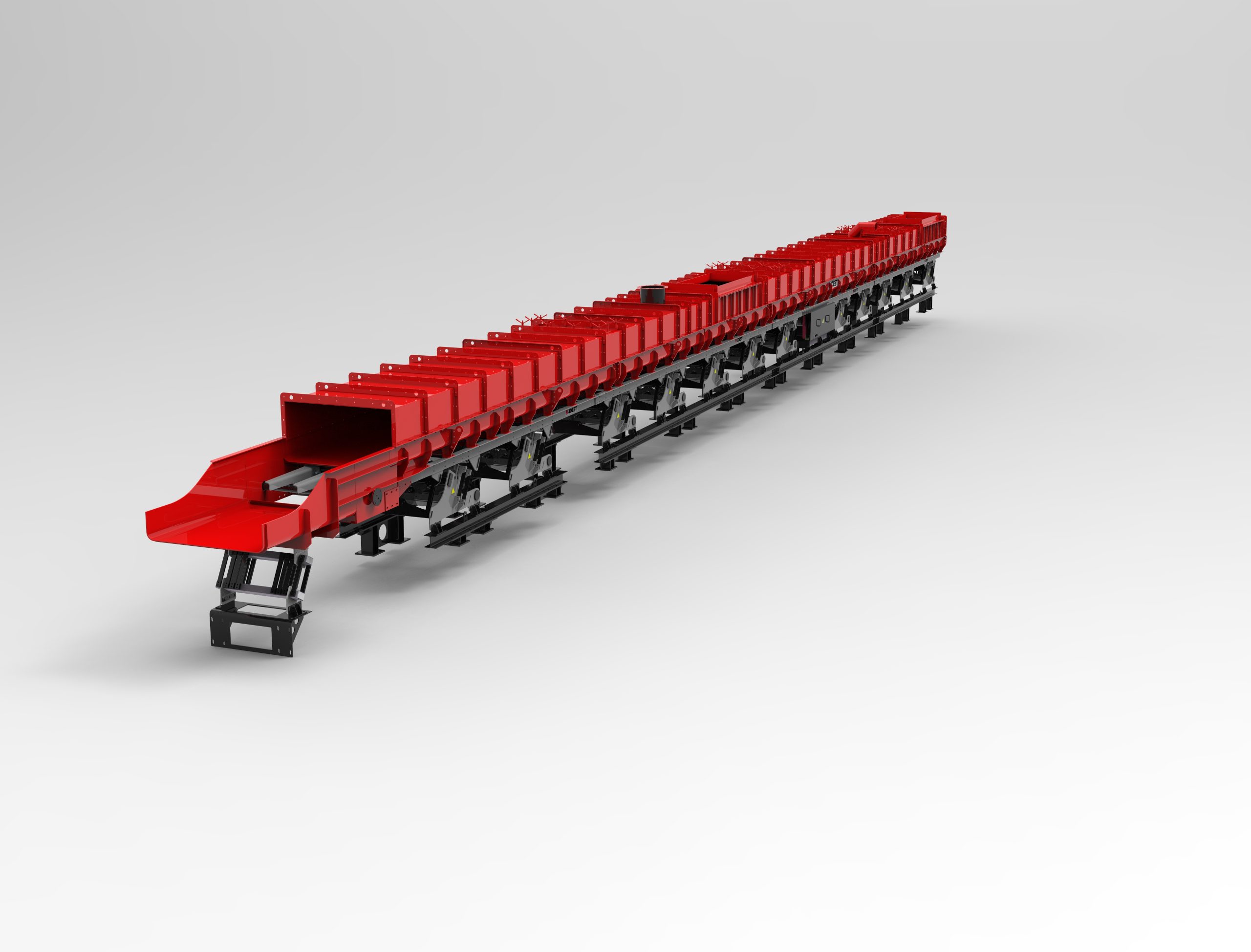

JOEST Motion Screen for Norsk Stein.

Back in 2008 and 2009, JOEST delivered a total of eight large, 3,070 x 7,000 mm, Linear Vibrating Screens to their client Norsk Stein in Jelsa. Norsk Stein is Norway’s leading producer of gravel and stone materials, producing more than 15 million tons of aggregates for the entire European market.

The JOEST Screens equip the secondary crushing plants with two parallel production lines for extremely abrasive granite. At a total capacity of 3,000 t/h, the material is classified from 125 mm down to 5 mm. In 2014, the plant was modified to focus more on the production of armourstone. An increased feed grain size and screen cuts of up to 220 mm became necessary. To achieve these new demands, one Linear Vibrating Screen was exchanged for a Double-Shaft Elliptical Motion Screen.

The positive experience with previous deliveries and the collaboration with the #JOESTeam as well as an increased demand for armourstone led to a new project. Last year, JOEST received the order to modify the second production line as well. An optimal concept for the exchange of the two machines was developed in close collaboration with the client.

Because the larger screen cuts of the first stage increased the material throughput, the following screen also had to be exchanged. Under the given parameters on site, the largest possible screening surface was implemented. An additional challenge was to modify the existing support structure, adjust all material transitions and create an installation concept.

Building on the experience gained from the first Elliptical Motion Screen, the new first stage machine was further improved. Wear liners on the side walls, feed and discharge ends as well as the traverse beams were optimized to ensure longer runtimes and quick and easy maintenance. The screen deck consists of extremely heavy, wear resistant rubber panels. Despite the large screen cuts, the machine runs nearly without pegging.

The challenge with the second screen was to meet classification standards even at higher throughput rates for the screen cuts 16 and 5 mm. Especially the fine fraction tends to clog the screen. With the solution designed by JOEST, one of the worlds largest Elliptical Motion Screens measuring 3,500 x 7,000 mm was manufactured and delivered. The acceleration rates of the screen are above average and in combination with flexible PU screen mats on the lower deck, a high screening quality is achieved.

Manually screen is no longer neccessary thanks to the self-cleaning effect, resulting in a significant cost reduction whilst maintaining the same high quality.

Both screens have a vibratory weight of more than 30 tons and are mounted to isolation frames of 18 tons. Each are driven by two oil-lubricated circular exciter cells that enable effective screen widths beyond the previously known limit of 3,000 mm for circular motion screens.

Due to the weight and size of both machines, shipping and transport were another challenge. After successfully loading on trucks at JOEST, the machines were loaded onto chartered cargo ships at Hamburg Harbor. Since End of May, the machines are operating.

The client’s expectations regarding performance, efficiency and availability were exceeded. Particularly the very good project management was

underlined.