JOEST USA

New construction in the USA

JOEST USA Completes Expansion of Product Lines and Production Capacity.

![]()

JOEST USA just completed the merger of production capabilities with GOESSLING USA in the fall of 2021, which followed the commercial integration of the two companies in the spring of this year. What started in 2006 with a single, 500 square foot office in the Chicago Area, has now grown to become one of North America’s largest designers and manufacturers of non-belt conveying, screening, air separating and tipping equipment.

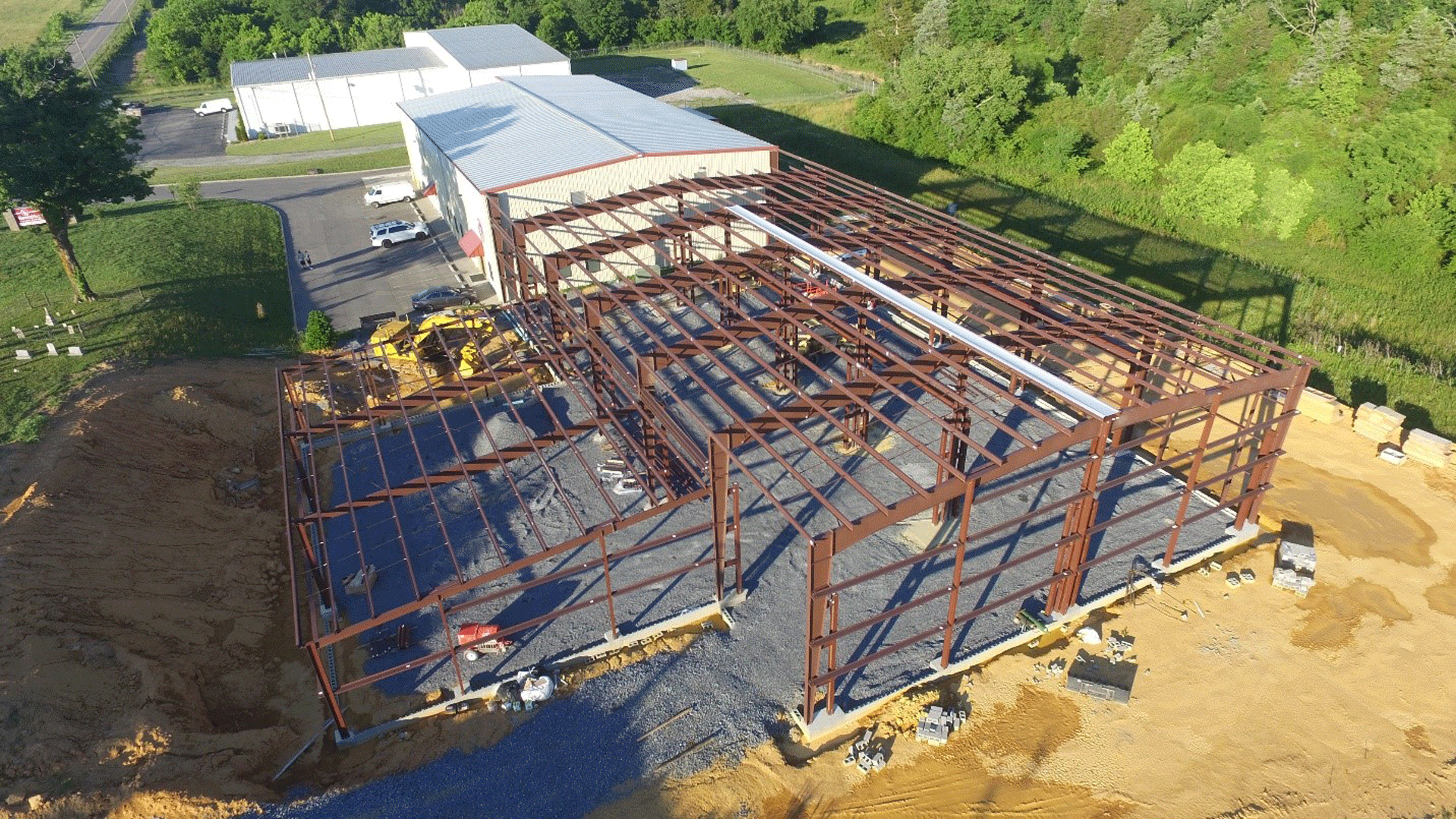

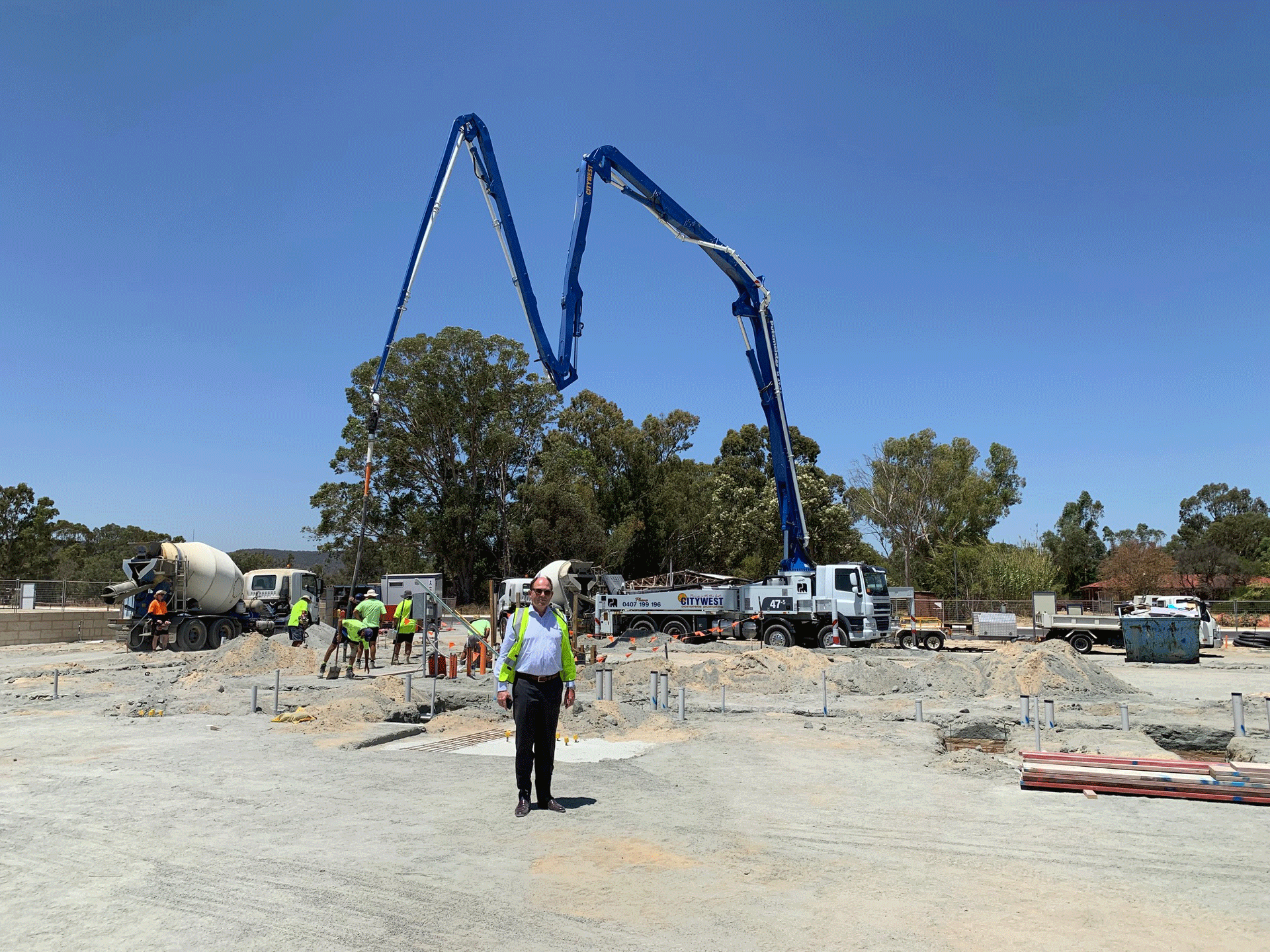

In November 2021, JOEST completed an over 15,000 square foot expansion of the production facility in Piney Flats, TN. This expansion more than doubled the production floor space as well as increased the production height and crane capacity to build even larger screens and longer conveyors in the US. The production floor is designed with a custom-built isolation pad that allows large conveyors and screens to be tested without transmitting destructive vibration to the frame of the building. While the intent was to build a space larger than the current needs, JOEST’s continued growth in new and existing markets has quickly filled up almost all the new capacity.

“We had been looking for several years to expand our production capacity in the US, but it’s been hard to find existing buildings with the right height, length and crane capacity to meet our slightly unusual production space requirements” commented Steve Rowland, General Manager of JOEST USA. “So we built the space to meet our exact needs.”

The space also leverages the growing work force and access to transportation routes that have been part of Northeastern Tennessee’s rapid growth over the last few years. With the expansion has come the need to increase the number of engineers and production personnel as well. It also significantly increased our warehouse capacity so that we can stock even more spare parts and drives close to where our customers need them.

To complete the seamless integration of the two companies, the EPR and communications systems will also be integrated by the end of the year. Then customers will have just one number to call and one place to go for all their material handling needs.

“We had been looking for several years to expand our production capacity in the USA, but it’s been hard to find existing buildings with the right height, length and crane capacity to meet our slightly unusual production space requirements”

Steve Rowland

General Manager, JOEST USA

Weitere Beiträge

JOEST delivered two high-performance vibrating feeder including tunnel frame, discharge chute and needle gate, each one feeding gabbro up to an edge length of 700 mm as a free stockpile discharge. Our focus was on a robust, blockage-free, wear-optimized and installation-friendly design.

Under the motto #JOESTogether, we organized for the first time an EM pack-watching on our site. It was a fantastic event where we celebrated our community and team spirit.

On the occasion of the farewell of the long-serving managing director, the entire staff of JOEST organized a collective fundraising campaign for the nearby children’s hospice Gut Feismann. A total of over 1,200 euros was collected by the #JOESTeam and ultimately rounded up to 3,500 euros by the management.

Münster

The Job Fair 2024 in Münster was a complete success for us. We are especially proud of our first-time participation as exhibitors.