SECUNDARY RAW MATERIALS

Top quality with JOEST Classification System

Innovative concrete recycling plant in the Netherlands equipped with JOEST Circular Motion Screens and Vibrating Trough Type Feeders.

Three JOEST Zig Zag Separators delivered to SKAPA in Austria last year.

In July 2018 JOEST was commissioned by the company SKAPA Recycling to deliver three Zig Zag Separators. Their task is to separate light materials from heavy materials to produce a pure aluminum can fraction.

The separator feed material has a grain size of 0–70/80 mm and is comprised mainly of shredded aluminum cans and contaminant materials. Among the heavy contaminant materials are rocks and bulky nonferrous metals such as brass, copper, and stainless steel. The light contaminants include film, lint, dust, and empty juice boxes.

The task of the first separator consists in separating out light contaminant materials such as lint, film, dust, and empty dog/cat food pouches. For the customer, it was extremely important for the last items to also be separated out by the JOEST Zig Zag Separators. This is not easy because they are made of an aluminum–PET film composite and hence the weight difference between them and the good material is very small.

The two other separators should separate out heavy contaminant materials such as bulky nonferrous metals and any rocks present.

In order for a perfect sorting result with clean aluminum can fractions to be obtained, the material is screened at 30 mm and each fraction is fed into another JOEST Zig Zag Separators for heavy contaminant removal. It is especially pleasing that even aluminum tubes containing residues such as mustard can be sorted out thanks to the innovative JOEST technology.

JOEST Zig Zag Separators also feature postseparation stages for the upper part of the separator channel with which heavy parts in the light stream can be fed back into the heavy stream. “We are impressed that JOEST was able to find and implement such precise solutions for our material,” says the CEO of SKAPA.

Since it was commissioned in mid-2018, the system has been running perfectly and delivering end products with top quality.

Weitere Beiträge

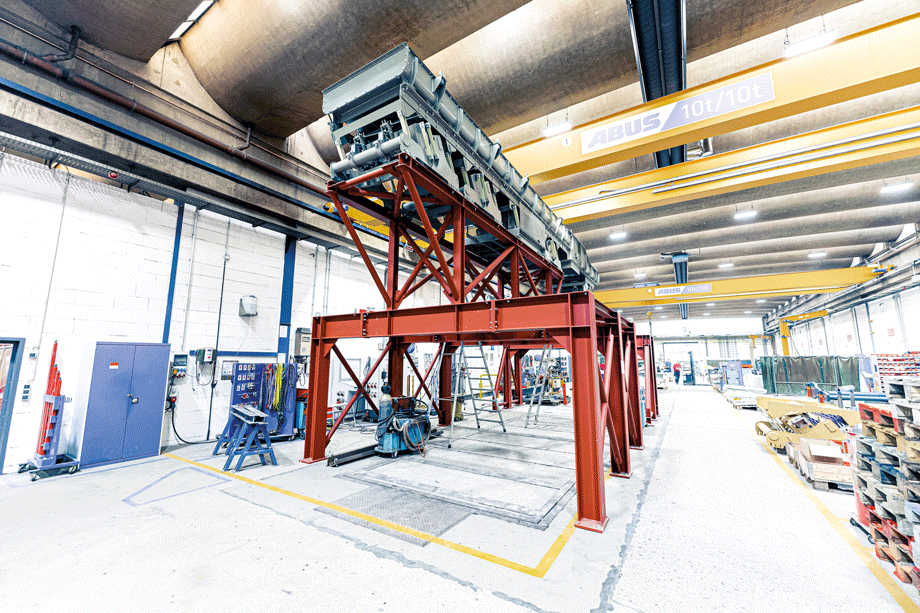

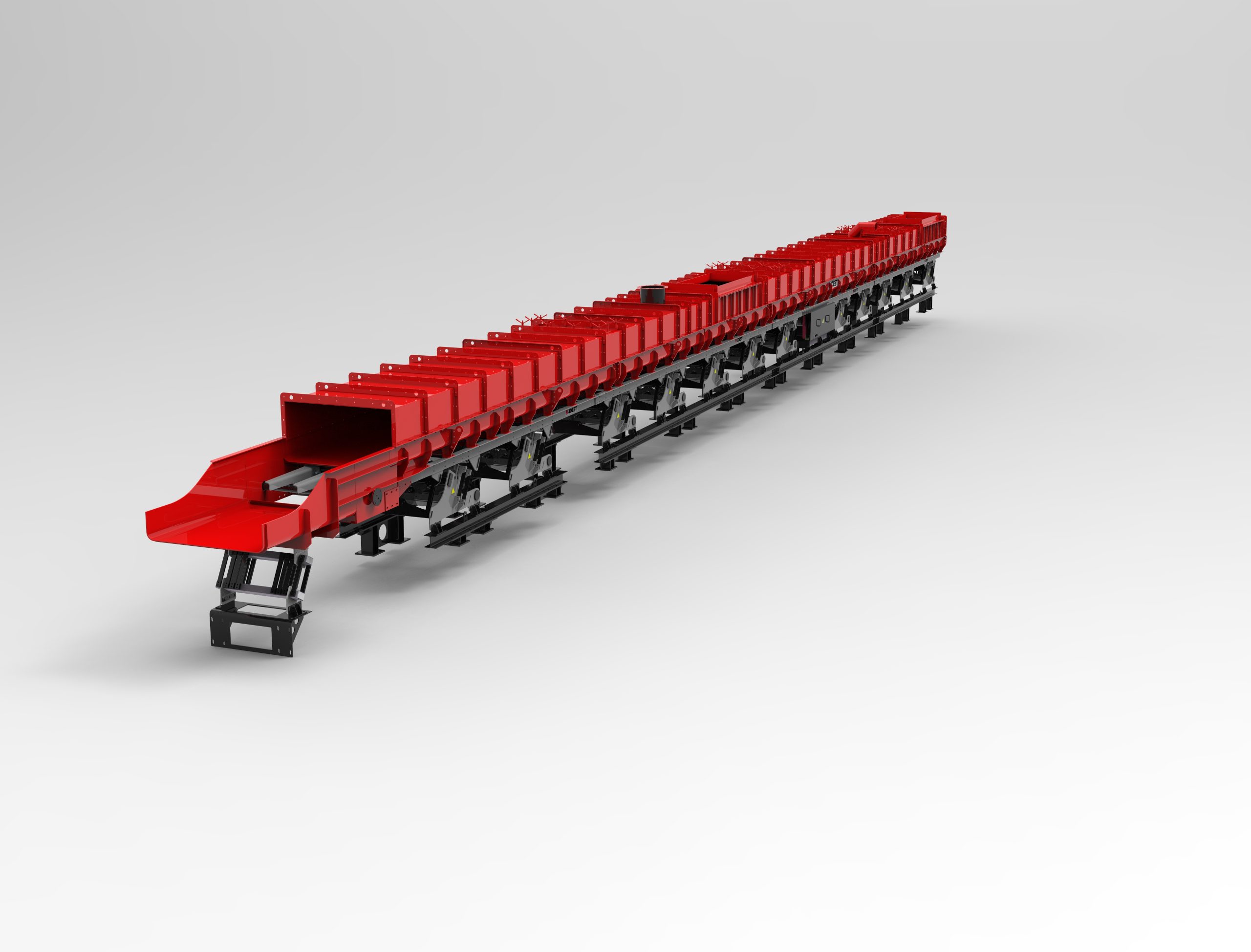

JOEST delivered two high-performance vibrating feeder including tunnel frame, discharge chute and needle gate, each one feeding gabbro up to an edge length of 700 mm as a free stockpile discharge. Our focus was on a robust, blockage-free, wear-optimized and installation-friendly design.

Under the motto #JOESTogether, we organized for the first time an EM pack-watching on our site. It was a fantastic event where we celebrated our community and team spirit.

On the occasion of the farewell of the long-serving managing director, the entire staff of JOEST organized a collective fundraising campaign for the nearby children’s hospice Gut Feismann. A total of over 1,200 euros was collected by the #JOESTeam and ultimately rounded up to 3,500 euros by the management.

Münster

The Job Fair 2024 in Münster was a complete success for us. We are especially proud of our first-time participation as exhibitors.