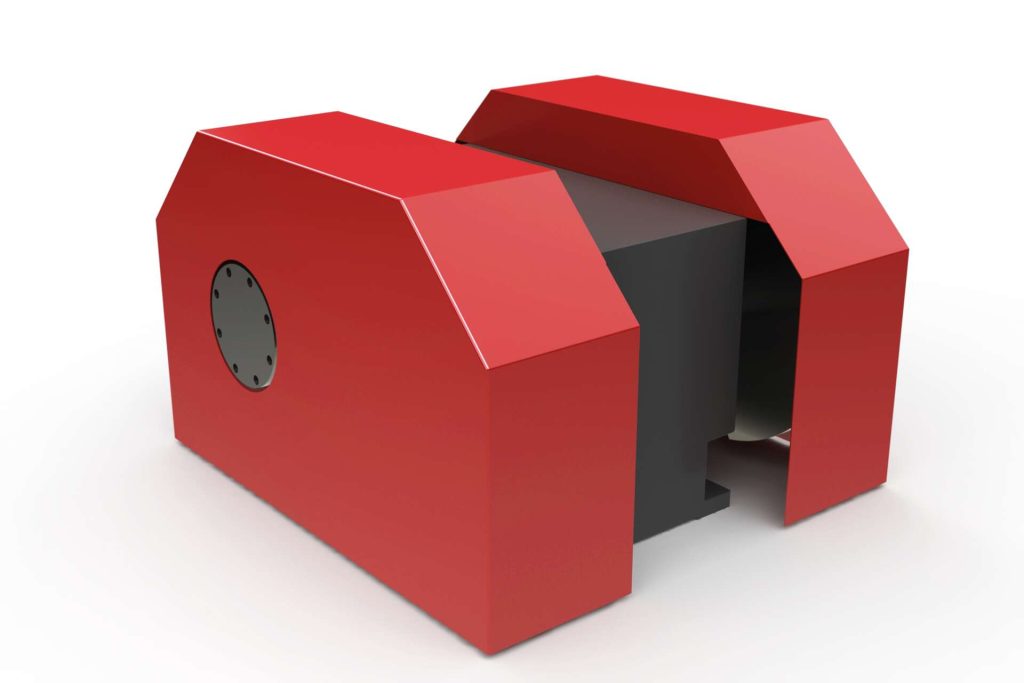

JVM® Exciter

JR rectangular vibrators are robust electromagnetic drives designed to generate linear vibrations and specifically engineered for use in orientation and conveying systems. With their compact design, high reliability, and steplessly adjustable stroke, they are ideally suited for tasks such as orienting, sorting, and conveying piece goods or bulk material flows.

Thanks to their precise vibration characteristics, processes can be controlled efficiently and adapted exactly to product-specific requirements. The JR series proves its value across a wide range of industries – from mechanical engineering and the automotive sector to electronics manufacturing – wherever precise positioning and conveying are essential.

FUNcTION

Scope of delivery

- Gear

- Flyweights

- Protection covers

- Connection flange

- Fan screw

- Manual

- Oil level stick

Advantages

- Long services lives

- Machine conservation

- Easy to maintain

- Variable parameters

Applications

JR rectangular vibrators are used wherever workpieces or bulk materials need to be precisely oriented, positioned, or separated – particularly in automated production and feeding processes.

Technical Data

The JVM® JR series rectangular vibrators are high-performance vibration exciters designed for reliable continuous operation in demanding industrial applications. They stand out with high working moments, versatile application options, and a rugged design that ensures maximum operational safety even under extreme environmental conditions.

6- and 8-Pole Designs

Available in 6- or 8-pole configurations to adapt rotational speed and vibration characteristics to the specific application.

Working Moments up to 20,400 kgcm (630 kN)

Deliver powerful vibration energy for the efficient operation of large and heavy machinery systems.

Adjustable Centrifugal Force

The generated centrifugal force can be flexibly adjusted to precisely match the vibration intensity to the conveying or screening process.

Continuous Duty – 100% (S1 Operation)

Designed for uninterrupted continuous operation at full power without the need for cooling intervals.

Ambient Temperature Range -40 °C to +80 °C

Reliable operation even under extreme climatic conditions – from arctic cold to tropical heat.