MSH-SERIES

LIFTING/TIPPING

MSH-Series

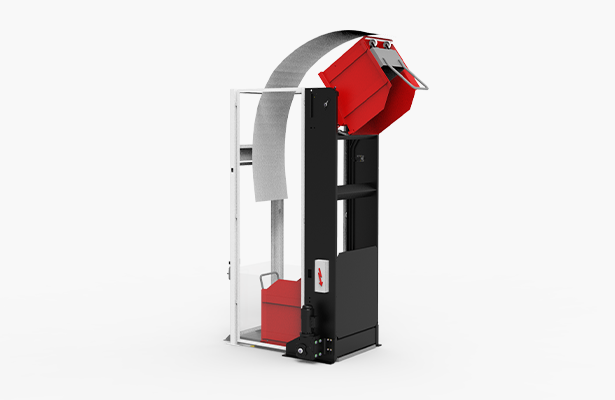

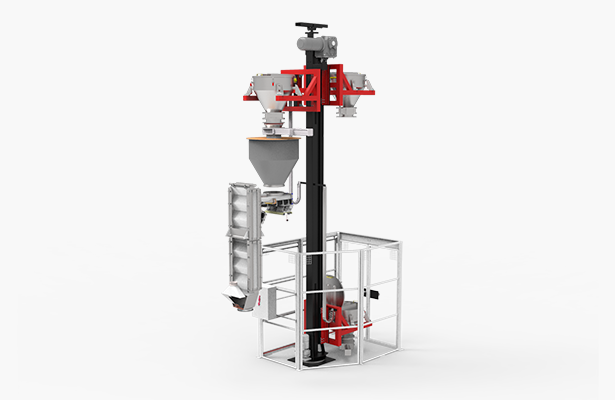

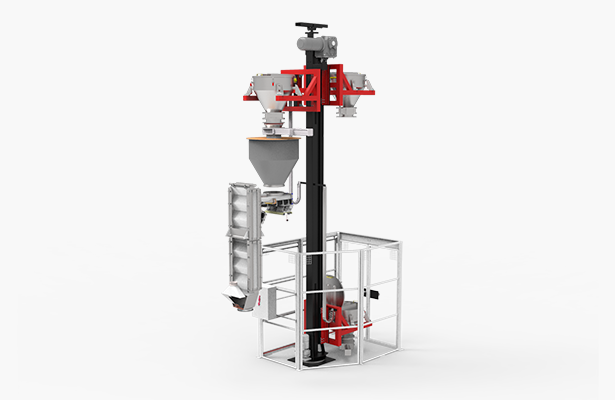

JOEST® Swivel Lifting Columns of the MSH Series can be used wherever containers need to be picked up, precisely positioned, retracted or swiveled from different positions and heights. The slim, three-dimensional JOEST swing-lifting column enables optimal space utilization and flexible container handling, which supports and accelerates the subsequent process technology. Thanks to the interplay of lifting and swiveling, the tipping of the input material is eliminated. Therefore, a product-friendly transfer process can be realized with minimized material mixing.

The vertical lifting column with top-mounted lifting drive is shifted on a slewing ring. This makes the swiveling process possible. The load-handling equipment can be equipped with a separate tipping drive that allows tipping up to 180 degrees.

The drives controlled by frequency converters ensure increased hoisting speed with reduced positioning speed in the end positions as well as exact positioning of the swivel lifting column. The compact design can achieve tipping heights of 500 mm to 12,000 mm with load-bearing capacity of up to 500 kg. If additional functions are required, these can also be implemented by means of various options. The high level of flexibility in the container feed enables power-saving and ergonomically designed handling, for example, by manual loading of the load-handling equipment at ground level.

The advantages of the MSH series include not only the reduction in energy expenditure, but also the time savings which an automatic tipping process provides. Various optional equipment help to optimize the tipping process and to provide the bulk material as best as possible for the subsequent process. Thus, a low-dust product transfers can be realized in connection with pneumatic container tension. By using an automatic container safety equipment, containers of different dimensions can be transported with the same lifting and swiveling column. In combination with conveyor systems an automatic feed and return of the containers is made possible.

By using containers with bottom discharge, a product-friendly and noise-reducing part-discharge is possible. Upon request, we manufacture containers specially designed to meet customer requirements, suitable for the swivel-lifting column, thus expanding the scope of delivery. The operationally safe tipping is adapted to your requirements through personal protection equipment. The MSH series is wired to a terminal box or is available complete with its own electrical control with various functions and operating modes for automated lifting and tipping.

The scope of application of the MSH series ranges from metallurgy, automotive, the chemical and plastics industries to the food and pharmaceutical industries. The material design is determined depending on the application. Thus, in addition to the design in normal steel, versions in stainless steel or mixed constructions are also possible. Likewise, requirements in a potentially explosive atmosphere (ATEX) or special hygiene and cleanliness regulations can be implemented.

- Closing lid in the bulk of the load carrier for gentle product transfer

- Various linings of the load carrier are available, these offer additional wear protection, serve for noise insulation or can contribute to an optimized material discharge

- Hydraulic container safety for different container dimensions

The MSH-Series

Read more about the MSH series, different designs and options here.

If you have any questions or are interested, please contact us directly!

BENEFITS

- Heavy construction for rough operation

- 2 pieces of load chainsand 2 pieces of safety chains each with 250,000 N breaking load

INDIVIDUAL

Options and Accessories

All lifting and tipping machines have a variety of different options and accessories to choose from. For example, you can be equipped with automatic chain lubrication, special coating in almost any RAL tone, container weighing, locking bolt securing to fix the load carrier, maintenance platforms on the machine head, PLC control, level monitoring, etc.

MD-SERIES

Designs

CONATCT FORM

Write to us!

Contact us quickly and easily via the following form. We will get back to you as soon as possible!

Alternatively, you can reach our head office at +49 2590

98-0.